Stainless Steel Sheet in Embossed with Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Product Description

Stainless steel sheet Detailed introduction

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

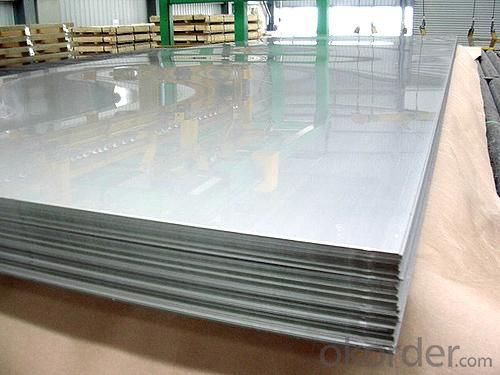

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for chemical storage vessels?

- Yes, stainless steel sheets are suitable for chemical storage vessels. Stainless steel is known for its excellent corrosion resistance, making it an ideal material for storing various chemicals. It is resistant to most acids, alkalis, and solvents, which ensures the integrity of the storage vessel and prevents any chemical reactions or leaks. Additionally, stainless steel is highly durable and can withstand high temperatures and pressure, making it suitable for a wide range of chemical storage applications.

- Q: Are stainless steel sheets suitable for elevator handrails?

- Yes, stainless steel sheets are suitable for elevator handrails. Stainless steel is a popular choice for handrails in elevators due to its durability, corrosion resistance, and aesthetic appeal. Elevator handrails are subject to constant use and exposure to various environmental factors, such as moisture and fingerprints. Stainless steel is highly resistant to corrosion, ensuring the longevity and maintenance-free operation of the handrails. Additionally, stainless steel has a sleek and modern appearance that complements the overall design of elevators. Its smooth surface is easy to clean and maintain, making it a hygienic choice for handrails in public spaces. Overall, stainless steel sheets are an excellent material choice for elevator handrails.

- Q: Can stainless steel sheets be used in automotive industry?

- Yes, stainless steel sheets can be used in the automotive industry. Stainless steel is a popular material choice in the automotive industry due to its various advantageous properties. It offers excellent resistance to corrosion, making it suitable for parts that are exposed to harsh weather conditions, such as car exteriors and body panels. Stainless steel sheets are also known for their high strength-to-weight ratio, which allows for the design and production of lightweight yet durable automotive components. Additionally, stainless steel is highly resistant to heat and can withstand high temperatures, making it suitable for applications such as exhaust systems. Overall, stainless steel sheets are widely used in the automotive industry for their durability, corrosion resistance, and versatility in various applications.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: What industries commonly use stainless steel sheets?

- Stainless steel sheets are extensively used in various industries due to their exceptional properties and versatility. One industry that commonly utilizes stainless steel sheets is the construction industry. Stainless steel sheets are used for roofing, cladding, and decorative purposes, providing durability, corrosion resistance, and an aesthetically pleasing appearance. Another industry that extensively uses stainless steel sheets is the automotive industry. Stainless steel sheets are used for manufacturing body panels, exhaust systems, and various components due to their high strength, heat resistance, and corrosion resistance properties. Additionally, stainless steel sheets are also used in the production of fuel tanks and other critical components in the transportation sector. The food and beverage industry also heavily relies on stainless steel sheets. These sheets are used for fabricating food processing equipment, storage tanks, and pipelines. Stainless steel sheets are preferred in this industry due to their resistance to corrosion, high cleanliness standards, and the ability to withstand extreme temperatures, ensuring hygienic and safe food processing. The medical and pharmaceutical industries also extensively use stainless steel sheets. These sheets are used for manufacturing surgical instruments, medical devices, and equipment due to their corrosion resistance, biocompatibility, and ease of sterilization. Moreover, the energy sector, including oil and gas, power generation, and renewable energy industries, commonly uses stainless steel sheets. These sheets are utilized for constructing pipelines, storage tanks, and various equipment in these industries due to their resistance to corrosion, high temperature, and pressure. Other industries that commonly use stainless steel sheets include aerospace, marine, chemical processing, and architectural industries. Stainless steel sheets provide the required strength, durability, and resistance to harsh environments in these sectors. Overall, stainless steel sheets find applications in a wide range of industries due to their exceptional properties, making them a preferred choice for various manufacturing and construction needs.

- Q: What is the maximum size of stainless steel sheets?

- The size of stainless steel sheets can differ based on the manufacturer and customer requirements. Generally, standard sizes for stainless steel sheets range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 5 feet by 10 feet (1.5 meters by 3 meters). Although some manufacturers may offer larger sizes like 6 feet by 12 feet (1.8 meters by 3.7 meters), these are rare and may need special ordering. It is important to note that custom sizes can be created by cutting or welding multiple sheets together, enabling larger dimensions if necessary.

- Q: How many steps do I need for stamping the stainless steel plate?

- Among the world's steel products, 60 to 70% are plates, most of which are finished by pressing. The car body, chassis, fuel tank, radiator plate, boiler drum, container shell, motor, electrical equipment, iron core, silicon steel sheet and so on are all stamping processing. Instruments and meters, household appliances, bicycles, office machinery, household utensils and other products, there are a large number of stamping parts.

- Q: What are the different types of corrosion that stainless steel sheets can resist?

- Stainless steel sheets are highly resistant to various types of corrosion, including general corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking.

- Q: What is the strength of stainless steel sheets?

- The strength of stainless steel sheets is one of its key advantages, as it possesses high tensile strength and can withstand heavy loads and impacts without easily deforming or breaking.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The quality and consistency of stainless steel sheets are ensured by several common manufacturing standards. One widely recognized standard is the ASTM International standard, formerly known as the American Society for Testing and Materials. Specifically, the ASTM A240 standard specifies the chemical composition, mechanical properties, and other relevant characteristics of stainless steel sheets. Another important standard is the EN standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers dimensions, tolerances, surface finishes, and more. Different countries also have their own national standards. For example, in Japan, stainless steel sheets are classified under specifications such as JIS G4304 and JIS G4305, which are part of the Japanese Industrial Standards (JIS). These standards define the chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in manufacturing, and their properties are defined by the AISI. Manufacturers and suppliers must adhere to these standards to ensure that stainless steel sheets meet quality requirements and can be reliably used in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across industries.

Send your message to us

Stainless Steel Sheet in Embossed with Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords