Stainless Steel Plate 304L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

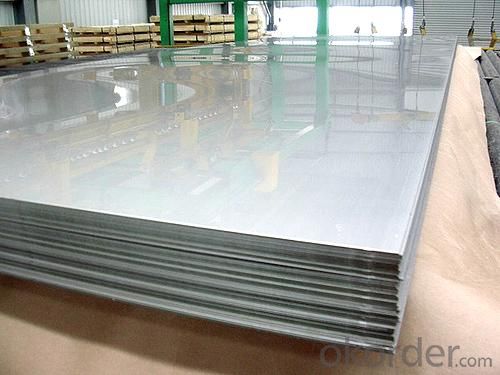

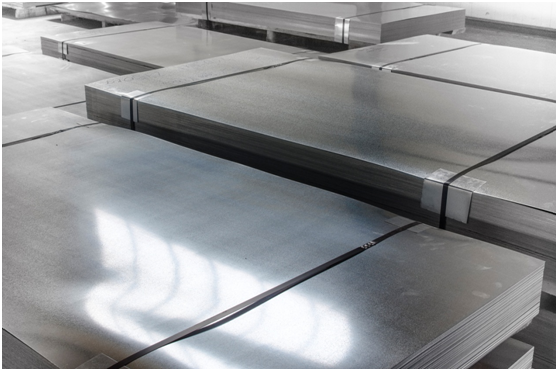

Stainless Steel Plate 304L with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

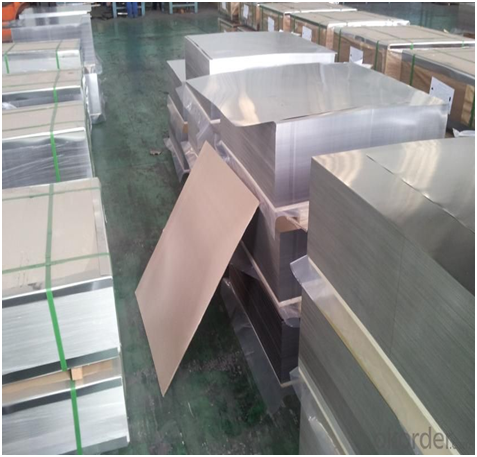

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

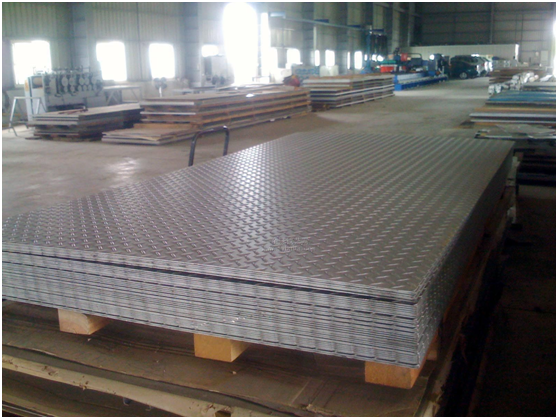

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the difference between the stainless steel plate and the second board?

- Stainless steel rolling will have uneven thickness significantly phenomenon, characteristics of whole plate on both sides of the middle thick thin stainless steel board material, generally does not appear such phenomenon

- Q: What is the price per square foot for stainless steel sheets?

- The cost of stainless steel sheets per square foot can fluctuate due to different factors, including the grade, thickness, finish, and supplier. Generally, the price range for stainless steel sheets is $3 to $10 per square foot. Nevertheless, superior quality and specialty options may have a higher price, reaching $20 or even more per square foot. Considering these variables and exploring different options is crucial in order to find the most suitable price for your specific needs.

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: Are stainless steel sheets suitable for desalination plants?

- Yes, stainless steel sheets are suitable for desalination plants. Stainless steel is highly corrosion resistant, making it ideal for applications in saltwater environments. It can withstand the harsh conditions of desalination plants, including exposure to saltwater, high temperatures, and pressure. Additionally, stainless steel is a durable and hygienic material, making it an excellent choice for desalination plant components such as heat exchangers, pipes, and tanks.

- Q: What are stainless steel sheets made of?

- Stainless steel sheets are made from a type of steel alloy that contains a minimum of 10.5% chromium. The addition of chromium creates a protective layer on the surface of the steel called a passive film, which makes stainless steel resistant to corrosion and staining. In addition to chromium, stainless steel sheets may also contain other elements such as nickel, molybdenum, and nitrogen, which enhance its mechanical properties and corrosion resistance. The specific composition of stainless steel sheets can vary depending on the desired properties and applications.

- Q: How to clean stainless steel plate cleaning?

- Grease can be applied to soft cloth to dissolve alcohol. I was impressed with how the grease turned off my pizza oven. Some thicker deposits did not respond once to a cloth, but I had been rubbing them with alcohol and completely disappeared within one or two minutes. With other methods, it is important to rinse off the alcohol and dry it so that it has a shiny metal.

- Q: What are the features of stainless steel plates?

- According to the method of hot and cold rolled two categories, including thickness 0.5.10-885 mm 72938 thin cold plate and 4.5-100 mm thick plate.

- Q: Are stainless steel sheets suitable for elevator flooring?

- Yes, stainless steel sheets are suitable for elevator flooring. They are durable, resistant to corrosion, easy to clean, and provide a sleek and modern look that complements the interior design of elevators.

- Q: Are stainless steel sheets suitable for marine environments?

- Yes, stainless steel sheets are suitable for marine environments. Stainless steel is highly resistant to corrosion and rust due to the presence of chromium in its composition. This makes it an ideal material for use in marine environments where constant exposure to saltwater and moisture can cause other metals to corrode quickly. Stainless steel sheets also have good mechanical properties, high strength, and excellent durability, which further make them suitable for marine applications. Additionally, stainless steel is easy to clean and maintain, ensuring its longevity and performance in harsh marine conditions.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets may differ based on their thickness and dimensions. Typically, stainless steel sheets possess a density of 8 grams per cubic centimeter. To determine the weight of a stainless steel sheet, one must acquire the dimensions (length, width, and thickness) and multiply them to ascertain the volume. Subsequently, the weight can be determined by multiplying the volume by the density.

Send your message to us

Stainless Steel Plate 304L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords