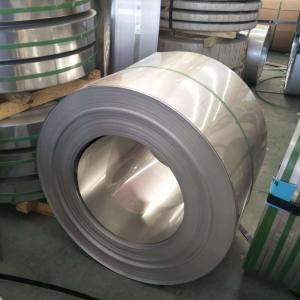

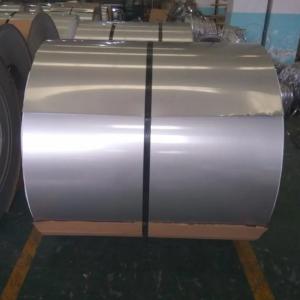

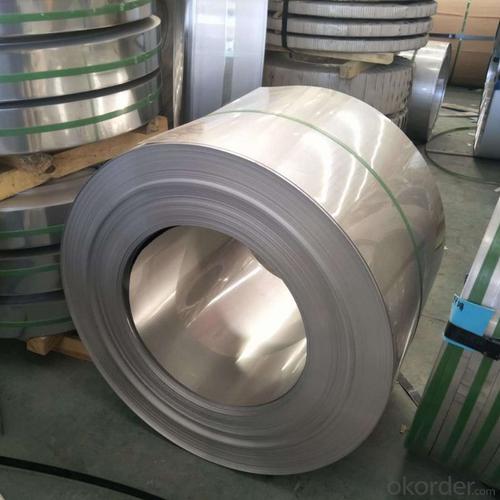

Stainless Steel Coils for Carbin Building Decoration JIS EN ASTM AISI

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

1

Width:

1000

Length:

2000

Net Weight:

19

Stainless steel which can be produced in different chemical, physical and mechanical properties, have high corrosion and heat resistance, mechanical strength, manufacturing ease, aesthetic appearance hygienic and long lasting properties.

STANDARDS

ASTM A240/A240M,ASME A240/A240,EN 10088-2, EN10028-7,JIS G 4305

| Hot Rolled Stainless Steel Coil | |

| Size | Thickness 2.8mm-14mm, Width can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

| Finish | 1D, No.1 finish, black finish |

| Cold Rolled Stainless Steel Coil | |

| Size | Thickness 0.02mm-3mm, Width can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

| Finish | 2B, 2D, BA, NO.3, NO.4, SB, NO.8, HL |

| Application | Elevator, Carbin Decoration, Building Decoration, Architectural Decoration, Kitchen Decoration |

- Q: How do you clean stainless steel sheets?

- To clean stainless steel sheets, you can start by wiping them down with a soft cloth or sponge dipped in mild soapy water. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. Rinse the sheets thoroughly with clean water and dry them with a soft towel to prevent water spots. For stubborn stains or fingerprints, you can use a stainless steel cleaner or a mixture of vinegar and water. Gently scrub the affected areas with a soft cloth, rinse, and dry.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Indeed, stainless steel sheets prove to be apt for cryogenic applications. Renowned for its commendable mechanical attributes like remarkable strength and resilience, stainless steel emerges as an ideal choice for environments characterized by low temperatures. Furthermore, stainless steel exhibits an impressive ability to resist corrosion, a critical quality when confronted with cryogenic temperatures. It remains steadfast in maintaining its mechanical properties, steadfastly refusing to succumb to brittleness even in ultra-low temperatures. Consequently, stainless steel sheets find themselves widely employed in cryogenic applications such as storage tanks, pipelines, and equipment designed to handle liquefied natural gas (LNG), liquid nitrogen, and other cryogenic fluids.

- Q: Are stainless steel sheets suitable for railway station platforms?

- Yes, stainless steel sheets are suitable for railway station platforms. Stainless steel is a highly durable material that can withstand heavy foot traffic and extreme weather conditions, making it an ideal choice for platforms in railway stations. It is resistant to corrosion, which is crucial in areas exposed to moisture, such as platforms where rain, snow, or spilled liquids may occur. Stainless steel sheets are also easy to clean and maintain, ensuring a hygienic and safe environment for passengers. Additionally, stainless steel has a sleek and modern appearance, adding to the aesthetic appeal of the railway station. Overall, stainless steel sheets provide the necessary strength, durability, and aesthetic qualities required for railway station platforms.

- Q: Can stainless steel sheets be used for decorative ceiling tiles?

- Yes, stainless steel sheets can indeed be used for decorative ceiling tiles. Stainless steel is a versatile material that offers a modern and sleek appearance, making it a popular choice for decorative purposes. Its durability, resistance to corrosion, and ability to withstand high temperatures also make it suitable for ceiling applications. Additionally, stainless steel sheets can be easily customized with various finishes, patterns, and designs to create unique and visually appealing ceiling tiles.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- Stainless steel sheets can be finished with various edge treatments to achieve different appearances and functionalities. These finishes serve to enhance the sheet's aesthetics, protect against sharp edges and potential corrosion. 1. Mill Finish: The standard edge finish for stainless steel sheets is the raw, untreated edge produced during manufacturing. While it may have a slightly rough or uneven appearance, it is functional and commonly used in industrial applications. 2. Deburred Edges: To eliminate any sharp or jagged edges, the stainless steel sheet can undergo deburring. This involves grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly chosen in safety-sensitive applications like food processing or medical equipment. 3. Rounded Edges: Rounded edges are achieved by utilizing a rounding tool to smooth out the sharp corners of the stainless steel sheet. This finish not only enhances the sheet's aesthetics but also reduces the risk of injury from sharp edges. Rounded edges are often favored for architectural or decorative purposes. 4. Beveled Edges: By cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees, beveled edges are created. This chamfered edge adds a sleek and modern appearance to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to achieve a smooth and mirror-like finish. This edge treatment adds a touch of elegance and sophistication, making it suitable for high-end architectural or decorative applications. To sum up, stainless steel sheets can be finished with mill finish, deburred edges, rounded edges, beveled edges, or polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q: Can stainless steel sheets be used for food packaging or containers?

- Food packaging or containers can indeed utilize stainless steel sheets. The food industry widely employs stainless steel due to its numerous advantageous qualities. Its corrosion resistance guarantees that the food will not react with the container, ensuring safety for consumption. Moreover, stainless steel is highly durable, making it appropriate for long-term utilization in food packaging or containers. It is also effortless to clean and maintain, meeting the necessary hygiene standards. Furthermore, stainless steel containers or packaging can withstand extreme temperature changes, making them suitable for diverse food storage and transportation requirements. All in all, stainless steel sheets are a dependable and secure option for food packaging or containers.

- Q: How do you remove scratches from mirror-finish stainless steel sheets?

- Follow these steps to remove scratches from mirror-finish stainless steel sheets: 1. Begin by cleaning the surface using a mild detergent or stainless steel cleaner to eliminate dirt, grime, and oils. Make sure the surface is completely dry before proceeding. 2. Assess the scratch's depth by running your fingernail over it. Superficial scratches that are barely noticeable can be easily repaired, while deeper scratches may require professional assistance. 3. For minor scratches, utilize a non-abrasive cleaner or toothpaste. Apply a small amount to a soft cloth or sponge and gently rub the scratched area in a circular motion. Thoroughly rinse the area and wipe it dry with a clean cloth. 4. If the scratch remains visible after using a non-abrasive cleaner, try using a metal polish specifically designed for stainless steel. Apply a small amount to a clean, soft cloth and gently rub it onto the scratched area in a circular motion. Continue until the scratch fades away, then rinse and dry. 5. For deep scratches or extensive damage, consult a professional stainless steel restoration expert. They will assess the damage and recommend the best course of action, which may involve sanding and polishing the surface to restore its original mirror finish. Remember to test any cleaning or polishing products in an inconspicuous area first to avoid damage or discoloration. Always follow the manufacturer's instructions when using such products.

- Q: What is the maximum thickness available for stainless steel sheets?

- The specific grade of stainless steel and the manufacturing capabilities of the supplier can cause the maximum thickness of stainless steel sheets to differ. Nevertheless, stainless steel sheets are commonly available in thicknesses ranging from 0.5mm to 80mm. It should be emphasized that thicker sheets are typically utilized for specialized purposes that demand heightened strength and durability, like construction projects or heavy machinery. To ensure the desired thickness is obtainable, it is essential to carefully consider the intended use of the stainless steel sheets and seek advice from a reputable supplier.

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a durable and versatile material that is resistant to corrosion, making it suitable for outdoor applications. It can be cut into various shapes and sizes, allowing for customized signage and lettering designs. Additionally, stainless steel can be finished in different ways, such as brushed or polished, to achieve the desired aesthetic.

Send your message to us

Stainless Steel Coils for Carbin Building Decoration JIS EN ASTM AISI

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords