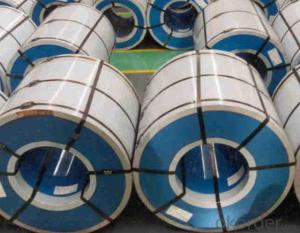

Prepainted Steel Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:0.42*1180mm, RAL9010

Surface Treatment:Coated

Technique:Cold Rolled

Standard:ASTM, JIS, GB, DIN, BS

Steel Grade:ASTM A755m, En10169

Thickness 0.20~1.10mm:Coil Width 600~1250mm

Export Markets:Global

Additional Info.

Trademark:HZZN

Packing:STANDARD EXPORT PACKAGE, IN 20′ CONTAINER

Standard:0.42*1180mm, RAL9010

Origin:China

HS Code:7210701000

Production Capacity:10, 000 Tons/Year

Product Description

Description of Prepainted steel coils:

1) Standard: JIS G3312 CGCC & CGLCC, equivalent to ASTM A755M, EN10169

2) Grade: CGCC and CGLCC

3) Hardness of material: Both soft and full hard are available

4) Surface finish: With or without protect film covered

5) Thickness range: 0.14-1.20mm

6) Width range and General width: Width range 600-1250mm, general width: 914mm, 1000mm, 1220mm and 1250mm.

7) Shape: Both sheet and coil are available

8) Zinc coating: 60-275G/M2, both sides

9) Paint thickness: Top 5 um + (10-20) um modified polyester, any RAL color code. We use Beckers paint for producing

| Standard | JIS G3312 CGCC ASTM A755M EN10169 |

| Valid thickness | 0.20~1.20mm |

| Coil width | 600~1250mm |

| Coil ID | 508mm & 610mm |

| Coil weight | 3~5 tons |

| Zinc coating | 80~275 g/m2 |

| Thickness of top paint | 15~25 microns |

| Thickness of reverse paint | 5~7 microns |

| Color | any RAL code |

| Package | vertical, eye to sky & horizontal |

| MOQ | 25 tons |

- Q: Whats the difference in composition? When LTCS is used generally?Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these?Thankyou very much in advance..

- Low Temperature Carbon Steel

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- All the stainless steel cleaners I've tried are fine for polishing, but they don't clean anything. A damp microfiber towel (the kind with loops like terry cloth) does a good job. You might be able to use plain water because the cloths are so good. Or mix up some dish soap in water and wet the towel with that. You can use windex if you want something more convenient.

- Q: What are the different types of steel coil handling equipment used during processing?

- There are several types of steel coil handling equipment used during processing, including coil cars, coil upenders, coil tilters, coil transfer cars, coil grabbers, coil lifters, and coil reels. These machines are designed to efficiently handle and maneuver steel coils of various sizes and weights, ensuring safe and smooth operations during the processing stages.

- Q: How are steel coils used in the production of agricultural equipment?

- Steel coils are used in the production of agricultural equipment as they are often shaped and formed into various components such as frames, chassis, and structural parts. These coils provide strength, durability, and stability to the equipment, making it capable of withstanding the demanding conditions and heavy workloads typically associated with agricultural tasks.

- Q: what does steel have inside of it that makes it rust.I need the answer fast!!!!!!!!!

- Steel is made adding carbon to iron.The iron in steel reacts with oxygen in the air, producing ferric oxide(Rust).

- Q: Why buy recycled steel and from where to buy?

- Recycling old steel is very advantageous to manufacturers because it is always cheaper to use recycled metal scrap in Dubai than to expensively mine iron ore to gain it. Lucky Groups is one the recognized company to deal in recycled steel.

- Q: Can steel and/or stainless steel turn rusty ?

- Steel will rust. Stainless Steel does not rust.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils are both widely used in various industries for their strength and durability. However, there are some key differences between the two that should be considered when choosing the appropriate material for a specific application. One of the main distinctions between steel coils and stainless steel coils is the composition of the materials. Steel coils are made primarily of iron and carbon, with other elements added to enhance specific properties. On the other hand, stainless steel coils are made of iron, carbon, and a significant amount of chromium, which gives them their unique corrosion-resistant properties. Due to the presence of chromium, stainless steel coils offer superior resistance to corrosion, tarnishing, and rust compared to regular steel coils. This makes stainless steel coils particularly suitable for applications in environments with high humidity, moisture, or exposure to corrosive substances. In contrast, steel coils are more prone to rust and may require additional protective coatings or treatments to prevent corrosion. Another significant difference is the appearance of the two materials. Stainless steel coils have a shiny and reflective surface, giving them an aesthetically pleasing look. They are commonly used in applications where appearance is important, such as kitchen appliances, architectural structures, or decorative purposes. Steel coils, on the other hand, have a matte or dull finish and are often used in industrial applications where appearance is not a primary concern. In terms of strength, both steel and stainless steel coils offer excellent mechanical properties. However, stainless steel coils generally exhibit higher tensile strength and greater resistance to high temperatures. This makes them suitable for applications that require strength, such as construction, automotive, or aerospace industries. Lastly, cost is a factor that should be considered when comparing steel coils to stainless steel coils. Steel coils are generally more cost-effective than stainless steel coils due to the lower cost of raw materials and simpler manufacturing processes. However, when the added value of corrosion resistance and longevity is taken into account, stainless steel coils may prove to be a more economical choice in the long run, as they require less maintenance and replacement. In conclusion, steel coils and stainless steel coils have different properties and characteristics that make them suitable for specific applications. Stainless steel coils offer superior corrosion resistance, a shiny appearance, and higher tensile strength, while steel coils are more cost-effective. The choice between the two ultimately depends on the specific requirements of the application, such as the environment, aesthetics, strength, and budget.

- Q: what is the refining process doing to raw materials in steel

- The refining process removes impurities. Impurities are anything that is not iron (Fe). Most steels are at least 98% iron, with a fraction of a percent of carbon, a dash of manganese, and traces of sulphur and phosphorus. These are called carbon steels. The non-iron elements are impurities found with the iron in the ore. A certain amount of carbon and manganese is beneficial to the strength of steel, so part of the refining process is designed to control the carbon and manganese content to give desired properties to the steel. Sometimes small amounts of these are added in the process. Besides the common carbon steels, there are many alloys of steel in use today. Alloying is done after the steel is refined to over 98% iron, and while it is a liquid. Various elements are added to the steel in controlled amounts to give it special properties. These include silicon, aluminum, magnesium, vanadium, beryllium, nickel and chromium, and sometimes molybdenum, tungsten and titanium. Alloy steels are still mostly iron, ususally at least 95%, but some stainless steels are only 75% iron because of large amounts chromium and nickel added to the mix.

- Q: I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

- This Site Might Help You. RE: How do I remove rust spots from stainless steel? I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

Send your message to us

Prepainted Steel Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords