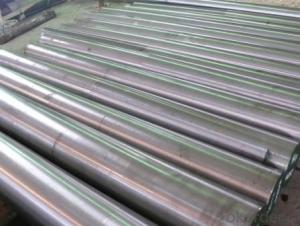

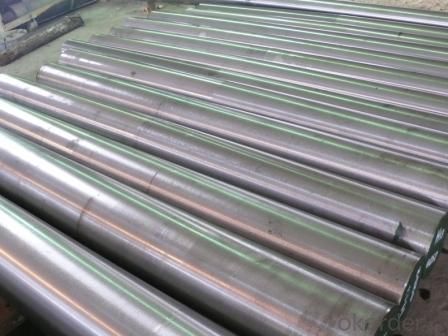

AISI 304 Stainless Steel Bar /stainless steel shafting bright surface

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What is stainless steel pipe?

- Stainless steel pipe is a type of pipe made from an alloy of steel and chromium, which provides excellent resistance to corrosion and oxidation. It is commonly used in various industries, including construction, automotive, and manufacturing, due to its durability, strength, and aesthetic appeal. Stainless steel pipes are known for their ability to withstand high temperatures and pressure, making them suitable for applications that involve transporting fluids and gases. Additionally, they are available in various sizes, shapes, and grades to meet specific requirements. Whether in residential or industrial settings, stainless steel pipes are widely used for plumbing, water supply systems, HVAC systems, and many other applications where durability and corrosion resistance are essential.

- Q: What is the difference between annealed and pickled stainless steel pipes?

- Annealed stainless steel pipes and pickled stainless steel pipes both undergo different processes that affect their properties and appearance. Annealing is a heat treatment process that involves heating the stainless steel pipes to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses and improve the ductility and toughness of the material. Annealed stainless steel pipes are usually softer and more malleable, making them easier to work with during fabrication and installation. They also tend to have a smoother, more polished surface finish. On the other hand, pickling is a chemical process that removes surface impurities such as oxides, scales, and rust from stainless steel pipes. It involves immersing the pipes in an acid solution, typically a mixture of nitric and hydrofluoric acid, which dissolves the impurities. Pickling helps to restore the corrosion resistance of the stainless steel and leaves a clean, bright, and uniform surface finish. In summary, the main difference between annealed and pickled stainless steel pipes lies in the processes they undergo. Annealing improves the material's ductility and toughness, while pickling removes surface impurities and restores corrosion resistance. The choice between annealed and pickled stainless steel pipes depends on the specific requirements of the application, such as the desired mechanical properties and surface finish.

- Q: What factory uses industrial stainless steel tube to be more?

- The automotive industry also has a lot of demand for stainless steel pipes. The main use of stainless steel is the exhaust system, which accounts for more than 1/2 of the total amount of stainless steel in the automobile, and 80% of the ferritic stainless steel. The exhaust gas from the automobile engine flows through the exhaust manifold, front pipe, hose, converter, and central pipe and finally flows out of the muffler. Commonly used in the exhaust system are 409L, 436L and so on. Automobile muffler mainly uses stainless steel pipe. According to estimates, the use of stainless steel pipes in the car accounted for the entire downstream of the stainless steel pipe about 1.5% of the amount, while the use of stainless steel seamless tubes and welded pipe ratio of about 2:1.

- Q: Are stainless steel pipes recyclable?

- Yes, stainless steel pipes are recyclable. Stainless steel is a highly sustainable material that can be recycled repeatedly without losing its properties or quality. Recycling stainless steel pipes helps conserve resources, reduce waste, and minimize environmental impact.

- Q: What are the different types of stainless steel pipe gaskets?

- There are several types of stainless steel pipe gaskets available, including ring gaskets, spiral wound gaskets, and sheet gaskets.

- Q: Can stainless steel pipes be used for paper and pulp industry applications?

- Stainless steel pipes are highly suitable for applications in the paper and pulp industry. This industry prefers stainless steel due to its exceptional resistance to corrosion, durability, and strength. Given the challenges posed by corrosive chemicals, high temperatures, and abrasive materials, stainless steel pipes are an optimal choice for a wide range of uses. These pipes are used to transport chemicals, steam, and water, as well as to convey pulp and paper products. Additionally, stainless steel pipes are hygienic, easy to clean, and do not cause contamination of the conveyed products. In summary, stainless steel pipes exhibit exceptional performance and durability in the demanding conditions of the paper and pulp industry.

- Q: Is stainless steel flexible enough for plumbing applications?

- Yes, stainless steel is flexible enough for plumbing applications. It can be easily bent and shaped to fit the required plumbing configurations, making it a versatile and commonly used material in the plumbing industry.

- Q: Can stainless steel pipes be used for chemical laboratories?

- Yes, stainless steel pipes can be used for chemical laboratories. Stainless steel is highly resistant to corrosion and chemical reactions, making it suitable for handling a wide range of chemicals and substances commonly used in laboratories. Additionally, stainless steel pipes are known for their strength, durability, and ease of maintenance, making them a reliable choice for laboratory applications.

- Q: What is the difference between 430 and 316 stainless steel pipes?

- The composition and properties of 430 and 316 stainless steel pipes differ significantly. 430 stainless steel, a ferritic stainless steel, contains chromium, providing it with good corrosion resistance. However, its resistance to corrosion falls short of that of 316 stainless steel. Furthermore, it has a lower nickel content compared to 316 stainless steel. In contrast, 316 stainless steel is an austenitic stainless steel that encompasses both chromium and nickel. It boasts exceptional corrosion resistance, rendering it suitable for a wide range of applications, particularly in marine environments where exposure to saltwater and other corrosive substances occurs. Additionally, it possesses superior tensile strength and creep resistance in comparison to 430 stainless steel. In terms of appearance, 430 stainless steel features a dull, brushed finish, whereas 316 stainless steel boasts a bright, reflective finish. Given these disparities, the selection between 430 and 316 stainless steel pipes hinges upon the specific application and the desired level of corrosion resistance.

- Q: Are stainless steel pipes resistant to abrasion?

- Stainless steel pipes possess remarkable resistance to abrasion, thanks to the exceptional characteristics of stainless steel, including its exceptional hardness and strength. Crafted from an alloy that comprises at least 10.5% chromium, stainless steel pipes are endowed with a protective coating on their surface, which efficiently thwarts rust and corrosion. This protective layer further aids in resisting abrasion, rendering stainless steel pipes an outstanding option for situations prone to intense wear and tear. Furthermore, stainless steel pipes exhibit remarkable heat resistance and durability, making them the perfect choice for industries like oil and gas, chemical, and construction.

Send your message to us

AISI 304 Stainless Steel Bar /stainless steel shafting bright surface

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords