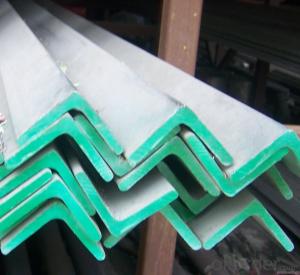

Stainless steel angle; angle steel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Informaiton of Stainless Steel Angle Bar

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry etc.

Specification of Stainless Steel Angle Bar

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: What are the different types of surface finishes for slotted stainless steel angles?

- There are several different types of surface finishes available for slotted stainless steel angles, each offering unique characteristics and benefits. Some of the common types of surface finishes for slotted stainless steel angles include: 1. Mill Finish: This is the most basic type of finish, which is achieved by leaving the stainless steel angle in its raw, unpolished state. It has a rough texture and may have visible imperfections, but it provides a natural and industrial look. 2. Brushed Finish: Also known as satin finish, this finish is achieved by brushing the surface of the stainless steel angle with abrasive material. It creates a consistent linear pattern with fine lines, giving the angle a smooth and even appearance. Brushed finish is commonly used for decorative purposes and provides a contemporary look. 3. Mirror Finish: This finish involves polishing the stainless steel angle to a highly reflective surface, resembling a mirror. It requires extensive polishing and buffing to remove any imperfections, resulting in a flawless and glossy appearance. Mirror finish is often used in architectural applications and provides a luxurious and elegant look. 4. Bead Blasted Finish: This finish is achieved by propelling fine glass beads onto the surface of the stainless steel angle under high pressure. It creates a textured and matte appearance, with a uniform pattern of small dimples or pits. Bead blasted finish is commonly used for aesthetic purposes, providing a unique and visually appealing texture. 5. Powder Coated Finish: In this finish, a dry powder coating is applied electrostatically to the surface of the stainless steel angle and then cured under heat. It provides a durable and long-lasting finish, available in a wide range of colors and textures. Powder coating offers excellent resistance to corrosion, scratches, and fading, making it suitable for both indoor and outdoor applications. These are just a few examples of the different types of surface finishes available for slotted stainless steel angles. The choice of finish depends on the desired aesthetic appeal, functionality, and environmental factors such as corrosion resistance and durability.

- Q: What are the different types of surface treatments for stainless steel angles?

- Stainless steel angles offer a variety of options for surface treatments. 1. Passivation is a commonly used treatment that utilizes chemicals to eliminate iron particles and contaminants from the stainless steel surface. This process enhances the material's resistance to corrosion. 2. Pickling involves immersing the stainless steel angles in an acidic pickling solution to eliminate oxide scale and heat tint. This treatment restores corrosion resistance and improves the overall appearance of the stainless steel. 3. Electropolishing is an electrochemical technique that eliminates a thin layer of material from the surface of stainless steel angles. It enhances the surface finish, eliminates irregularities, and improves corrosion resistance. 4. Coating is another option, where stainless steel angles can be coated with different materials such as epoxy, powder coating, or paint. These coatings provide an extra layer of protection against corrosion and enhance the aesthetic appearance. 5. For an enhanced surface finish, mechanical treatments such as grinding and polishing can be employed. These processes eliminate imperfections, scratches, and blemishes, resulting in a smooth and glossy surface. Each surface treatment offers unique advantages and is suitable for various applications. The choice of treatment depends on factors like desired appearance, corrosion resistance requirements, and the intended usage of the stainless steel angles.

- Q: What is a stainless steel angle?

- A stainless steel angle is a type of metal profile that features two sides that are perpendicular to each other, forming a right angle. It is made from stainless steel, which is an alloy of iron, chromium, and other elements that provide corrosion resistance and durability. The angle shape allows for structural support and reinforcement in various applications, such as construction, architecture, and manufacturing. Stainless steel angles can be found in a range of sizes and thicknesses, making them versatile for different projects. They are commonly used for framing, bracing, and supporting structures, as well as for decorative purposes. Due to the stainless steel material, these angles are resistant to rust, staining, and other forms of corrosion, making them ideal for both indoor and outdoor use.

- Q: Are stainless steel angles suitable for mezzanine floors?

- Yes, stainless steel angles are suitable for mezzanine floors due to their high strength and resistance to corrosion. They provide structural support and stability, making them a reliable choice for mezzanine floor construction.

- Q: What is the thermal conductivity of stainless steel angles?

- The thermal conductivity of stainless steel angles may vary based on the particular grade of stainless steel employed. In comparison to materials like aluminum or copper, stainless steel generally exhibits a moderately elevated thermal conductivity. The range of thermal conductivity for stainless steel angles is typically between 14 and 19 watts per meter-kelvin (W/m·K). Nevertheless, it is crucial to acknowledge that factors such as alloy composition, surface finish, and temperature can influence the thermal conductivity.

- Q: Can stainless steel angles be used in the automotive industry?

- Yes, stainless steel angles can be used in the automotive industry. Stainless steel offers excellent corrosion resistance, strength, and durability, making it suitable for various automotive applications such as frame structures, exhaust systems, brackets, and supports. Additionally, stainless steel angles can be easily fabricated and welded, making them a popular choice in the automotive industry.

- Q: Can stainless steel angles be used in the production of renewable energy systems?

- Yes, stainless steel angles can be used in the production of renewable energy systems. Stainless steel is a versatile and durable material that offers several advantages for renewable energy applications. Firstly, stainless steel is highly resistant to corrosion and rust, making it ideal for outdoor installations in renewable energy systems such as solar panels, wind turbines, and wave energy converters. These systems are often exposed to harsh environmental conditions, including moisture, saltwater, and extreme temperatures. By using stainless steel angles, the structural integrity of these systems can be maintained over a long period of time, ensuring their reliability and longevity. Secondly, stainless steel has excellent strength-to-weight ratio, meaning it can provide structural support while being relatively lightweight. This is particularly important in applications like solar panel frames and wind turbine towers, where a combination of strength and lightness is required for optimal performance and ease of installation. Furthermore, stainless steel is an environmentally friendly material itself. It is fully recyclable and can be reused in other applications, reducing waste and conserving resources. This aligns with the sustainability goals of renewable energy systems, making stainless steel angles a suitable choice for their production. Overall, the use of stainless steel angles in the production of renewable energy systems offers numerous benefits, including corrosion resistance, strength, lightness, and environmental sustainability. These qualities make stainless steel angles a reliable and efficient choice for supporting the growth and development of renewable energy technologies.

- Q: What are the different surface treatments for stainless steel angles?

- Some common surface treatments for stainless steel angles include polishing, brushing, passivation, and coating. Polishing gives the surface a smooth and reflective finish, while brushing creates a brushed or satin finish. Passivation is a chemical process that removes impurities and enhances corrosion resistance. Coating can involve applying a thin layer of paint, powder coating, or electroplating to provide additional protection and aesthetics.

- Q: What is the minimum angle measurement for stainless steel angles?

- The minimum angle measurement for stainless steel angles is typically 90 degrees.

- Q: What are the load distribution properties of stainless steel angles?

- The load distribution properties of stainless steel angles pertain to the effective and even distribution of weight and forces across the angle's surface when subjected to external forces or loads. Stainless steel angles are renowned for their robustness and durability, making them highly suitable for crucial load-bearing applications in construction and structures. Typically, stainless steel angles possess a consistent cross-sectional shape with two legs of equal length, joined at a right angle. This geometrical design ensures efficient load distribution along both legs, resulting in a balanced dispersion of weight and forces. The equal leg length aids in uniformly spreading the load across the entire angle, minimizing stress concentration and potential points of failure. Furthermore, stainless steel exhibits exceptional mechanical properties, such as high tensile strength and resistance to corrosion and fatigue. These attributes empower stainless steel angles to withstand heavy loads without deforming or succumbing to stress. The material's capacity to resist deformation and maintain its structural integrity guarantees an even distribution of load across the angle's surface, thereby enhancing its load-bearing capability. Moreover, stainless steel angles often possess a polished and smooth surface, which further facilitates uniform load distribution. The smoothness of the surface reduces friction and enables more efficient transfer of forces along the angle, preventing localized stress concentrations and promoting even load dispersion. In conclusion, the load distribution properties of stainless steel angles are characterized by their consistent cross-sectional shape, robust strength, and resistance to deformation. These features enable stainless steel angles to effectively distribute loads and forces, making them reliable structural components in various applications where load-bearing capacity is crucial.

Send your message to us

Stainless steel angle; angle steel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords