Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM 316l Stainless Angle Steel Bar

Main Structure of Angle Steel Bar

1.Surface:Bright,Polished,Turn smooth(Peeled),Brush,Mill,Pickled

2.Length:3m, 6m,9m,12m

3.Use:These products are widely supplied to areas of machine-made industry,chemical industry,spin,shipping industry,architecture,food industry,household products etc

4 ISO9001:2008

Data Information of Angle Steel Bar

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37, etc |

Technical parameters:

1) Material: Q235B , Q 345B, SS400 ,SS540, S235JR ,ETC. | |||

| 2) Usage: structure construction and electronic tower building | |||

| 3) Weight tolarance: -4% TO -10% | |||

| 4) Size tolarance : | |||

| ANGLE STEEL SIstructural steel angleE TOLARANCE (MM) | |||

| SIstructural steel angleE cm | WIDTH b/mm | THICKNESS d/mm | LENGTH /m |

| 2-5.6 | +/-0.8 | +/-0.4 | 4-12 |

| 6.3-9 | +/-1.2 | +/-0.6 | 4-12 |

| 10-14 | +/-1.8 | +/-0.7 | 4-12 |

| 16-20 | +/-2.5 | +/-1.0 | 4-12 |

| 5) Payment terms: TT or LC | |||

| 6) Delivery date: within 30 days after receiving the LC or TT prepay | |||

| 7) Packing: Export package | |||

| 8) Inspection: accept third party inspection | |||

Specification of Angle Steel Bar

1.Square bar:Size: 4mm*4mm~100mm*100mm

2.Round Bar:Diameter: 3mm~800mm

3.Angel Bar:Size: 3mm*20mm*20mm~12mm*100mm*100mm

4.Flat bar:Thickness: 2mm~100mm,Width: 10mm~500mm,

5.Hexagonal :Size: 2mm~100mm

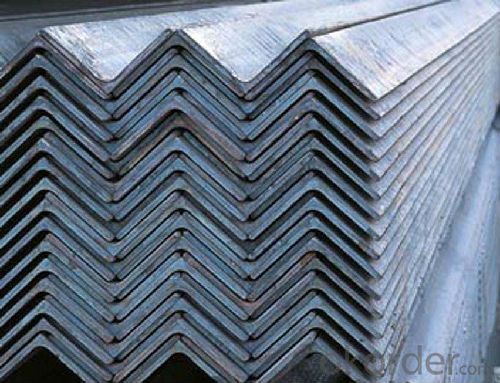

Picture

- Q: What are the load-bearing capacities of stainless steel angles?

- The load-bearing capacities of stainless steel angles vary depending on several factors such as the size, shape, and grade of the stainless steel angle, as well as the specific application and environmental conditions. Stainless steel angles are commonly used in structural applications where strength and corrosion resistance are required. They are often used as supports or brackets in construction, industrial, and architectural projects. The load-bearing capacity of a stainless steel angle is determined by its cross-sectional area, which is influenced by the dimensions of the angle, including the thickness of the material and the length of the legs. Additionally, the grade of stainless steel used can affect its load-bearing capacity, as different grades have different mechanical properties. To determine the load-bearing capacity of a specific stainless steel angle, it is necessary to consult engineering resources such as design manuals, technical specifications, or consult with a structural engineer. These resources provide guidelines and formulas for calculating the safe load capacity based on the specific dimensions and material properties of the angle. It is important to note that load-bearing capacities should always be determined by a qualified professional, as incorrect calculations or assumptions can lead to structural failure or safety hazards.

- Q: How do you calculate the moment of resistance for an unequal leg stainless steel angle?

- In order to determine the moment of resistance for an unequal leg stainless steel angle, one must take into account the properties of the angle section and utilize the appropriate formulas. The moment of resistance indicates the angle's ability to withstand bending and is determined by its geometry and material properties. To calculate the moment of resistance, follow these steps: 1. Measure the dimensions of the angle: Obtain the lengths of each leg and the thickness of the angle. These measurements will be necessary for further calculations. 2. Calculate the moment of inertia: The moment of inertia is a geometric characteristic that describes the distribution of mass around an axis. For an unequal leg angle, it is necessary to calculate the moment of inertia for both the x-axis and y-axis. The specific formulas for calculating the moment of inertia can be found in engineering handbooks or online resources. 3. Determine the yield strength of the stainless steel: The yield strength is a material property that represents the maximum stress the stainless steel can endure without experiencing permanent deformation. This information can typically be obtained from material specifications or testing. 4. Utilize the moment of resistance formula: The moment of resistance (M) can be determined using the equation M = fy * Z, where fy represents the yield strength of the stainless steel and Z denotes the plastic section modulus. The plastic section modulus is obtained by dividing the moment of inertia by the distance from the neutral axis to the outermost fiber of the angle section. 5. Insert the values into the equation: Substitute the yield strength and the plastic section modulus into the equation to calculate the moment of resistance for the unequal leg stainless steel angle. Please note that these calculations are based on simplified assumptions and may not account for all potential factors. For critical applications or specific design requirements, it is advisable to consult a qualified structural engineer or refer to applicable design codes and standards.

- Q: Can stainless steel angles be used in water treatment facilities?

- Yes, stainless steel angles can be used in water treatment facilities. Stainless steel is resistant to corrosion and can withstand the harsh conditions and chemicals commonly used in water treatment processes. It provides durability and longevity, making it an ideal choice for constructing various structures and equipment in these facilities.

- Q: What are the factors that affect the cost of stainless steel angles?

- The factors that affect the cost of stainless steel angles include the grade and quality of stainless steel used, the size and dimensions of the angles, the quantity purchased, market demand and supply, and any additional processing or finishing required. Other factors such as transportation costs, tariffs, and fluctuations in raw material prices may also impact the overall cost.

- Q: What are the maintenance requirements for stainless steel angles?

- To ensure the longevity and optimal performance of stainless steel angles, regular maintenance is necessary. Here are some key maintenance tips for stainless steel angles: 1. Keep them clean: Regularly clean stainless steel angles to remove any dirt, dust, or debris that may accumulate on the surface. You can use a mild detergent or cleaner along with a soft cloth or sponge. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. 2. Avoid harsh chemicals: It's important to steer clear of harsh chemicals or cleaners containing chlorine or bleach, as these can corrode the surface and cause damage. Instead, opt for mild, non-abrasive cleaners specifically designed for stainless steel. 3. Remove stains and spots: If stains or spots appear on stainless steel angles, you can remove them by using a mixture of baking soda and water or a stainless steel cleaner. Apply the cleaner to the affected area and gently scrub with a soft cloth or sponge, following the grain of the stainless steel. 4. Prevent scratches: Although stainless steel is highly durable, it can still get scratched, especially when exposed to abrasive materials or rough handling. To prevent scratches, avoid using abrasive cleaning tools and handle stainless steel angles with care. 5. Protect from corrosion: While stainless steel is resistant to corrosion, certain conditions can still lead to corrosion over time. To protect stainless steel angles from corrosion, avoid prolonged exposure to saltwater, acidic or alkaline substances, and high humidity environments. If the angles are installed outdoors, consider applying a protective coating or using a stainless steel grade designed for outdoor use. By adhering to these maintenance requirements, stainless steel angles can maintain their appearance, durability, and performance for many years, ensuring they continue to serve their intended purpose effectively.

- Q: How do you calculate the bending resistance for torsion of a stainless steel angle?

- To calculate the bending resistance for torsion of a stainless steel angle, you need to consider a few factors. First, you need to determine the moment of inertia of the angle. The moment of inertia is a measure of the resistance of an object to changes in its rotational motion. For an angle, the moment of inertia can be calculated using the formula I = (b * h^3) / 12, where b is the width of the angle and h is the height of the angle. Next, you need to calculate the modulus of elasticity for stainless steel. The modulus of elasticity is a measure of the stiffness of a material and is denoted by the symbol E. The value of E for stainless steel can be obtained from material property data or handbooks. Once you have the moment of inertia and modulus of elasticity, you can calculate the bending resistance for torsion using the formula R = (E * I) / L, where R is the bending resistance, E is the modulus of elasticity, I is the moment of inertia, and L is the length of the angle. It is important to note that this calculation assumes the stainless steel angle is subjected to pure torsion and is free from any additional loads or constraints. Additionally, it is always advisable to consult relevant engineering codes, standards, or guidelines for more accurate and specific calculations based on the design requirements and the specific properties of the stainless steel being used.

- Q: What is the tolerance for stainless steel angles?

- The tolerance for stainless steel angles can vary depending on the specific requirements and standards set by manufacturers. However, in general, the tolerance for stainless steel angles is typically determined by the accepted industry standards, such as the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). These standards specify the permissible deviations in dimensions, straightness, and surface quality for stainless steel angles, ensuring consistency and quality in their manufacturing and usage.

- Q: Can stainless steel angles be used in construction?

- Yes, stainless steel angles can be used in construction. Stainless steel is a popular material choice in the construction industry due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel angles are commonly used in various construction applications, such as framing, support structures, staircases, handrails, and architectural designs. The angles provide strength and stability to the structures, ensuring their longevity and structural integrity. Additionally, stainless steel angles can withstand harsh weather conditions, extreme temperatures, and exposure to chemicals, making them suitable for both indoor and outdoor construction projects.

- Q: Can stainless steel angles be used for signage?

- Yes, stainless steel angles can be used for signage. Stainless steel is a durable and corrosion-resistant material, making it well-suited for outdoor applications such as signage. Stainless steel angles can be used to create frames or supports for signs, providing stability and a sleek, professional appearance. The material is also easy to clean and maintain, ensuring that the signage will remain in good condition for a long time. Additionally, stainless steel has a modern and stylish look, making it a popular choice for various types of signage, including commercial, residential, and industrial applications.

- Q: Can stainless steel angles be used in storage tank manufacturing?

- Yes, stainless steel angles can be used in storage tank manufacturing. Stainless steel is a preferred material for storage tanks due to its excellent corrosion resistance, durability, and strength. Stainless steel angles are commonly used to reinforce the structure of storage tanks, providing additional support and stability. The angles are typically welded or bolted together to form the tank's framework, ensuring it can withstand the internal pressure and external forces. Moreover, the smooth and polished surface of stainless steel angles makes it easier to clean and maintain the storage tank, which is crucial in industries like food and beverage, pharmaceuticals, and chemical storage. Therefore, stainless steel angles are a suitable choice for storage tank manufacturing.

Send your message to us

Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords