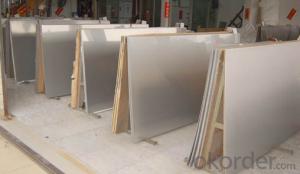

Stainless Steel 304 sheet for wholesale only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: Classification, advantages and disadvantages of stainless steel welding

- Metal gas shielded arc welding.It belongs to the gas protection welding, also is a kind of arc welding, that is, in the protection of gas, welding rod arc melting. Metal gas welding can be used in steel, non alloy steel, low-alloy steel and high alloy, etc. these materials are widely used. But one thing, its protective gas must be an active gas, such as carbon dioxide or a mixture of gases. The only drawback is that if the outdoor welding, then the workpiece can not be damp, otherwise it will affect the protection of gas protection effect.

- Q: Can stainless steel pipes be used for pharmaceutical processing equipment?

- Indeed, pharmaceutical processing equipment can utilize stainless steel pipes. The pharmaceutical industry highly favors stainless steel as it boasts exceptional resistance to corrosion, long-lasting durability, and effortless cleaning. Its ability to withstand chemicals, corrosion, and high temperatures renders it suitable for the manipulation and conveyance of a diverse range of pharmaceutical substances. Furthermore, stainless steel pipes possess a sleek surface that diminishes the likelihood of contamination and facilitates effortless cleansing and sterilization. In conclusion, stainless steel pipes find extensive use in pharmaceutical processing equipment, guaranteeing the integrity and excellence of pharmaceutical products.

- Q: How do you insulate stainless steel pipes?

- To prevent heat loss, condensation, and energy wastage, insulating stainless steel pipes is a crucial step. There are multiple effective methods available for insulating these pipes: 1. Pipe insulation wraps: The most common and cost-effective method involves using wraps made of materials like fiberglass, rubber, or foam. These wraps are easy to install and provide excellent insulation against heat transfer. They also serve as a barrier to prevent condensation. 2. Insulation jackets: Pre-formed covers made of insulation materials such as mineral wool or fiberglass are used for this method. These jackets are designed to fit around the stainless steel pipes and are secured with adhesive or straps. They offer a high level of thermal insulation and are ideal for pipes in areas with extreme temperatures. 3. Spray foam insulation: This method entails spraying a layer of polyurethane foam insulation directly onto the stainless steel pipes. This creates a seamless and durable insulation layer that adheres well to the pipes, providing excellent thermal insulation and preventing moisture buildup. 4. Insulation tape: Foam or rubber insulation tape is wrapped around the stainless steel pipes to provide thermal insulation. This method works best for smaller pipes or areas with limited space. Regardless of the chosen method, it is important to consider the temperature range, moisture exposure, and specific requirements of the stainless steel pipes when selecting insulation materials. Additionally, proper installation and maintenance of the insulation are essential to optimize its effectiveness and durability.

- Q: What is the difference between seamless and ERW stainless steel pipes?

- Seamless and ERW (Electric Resistance Welded) stainless steel pipes are two different types of pipes used in various applications. The main difference between these two types lies in their manufacturing process and physical characteristics. Seamless stainless steel pipes are manufactured without any welding seam. They are made by extruding a solid billet of stainless steel through a die to form the desired shape and size. This process ensures a smooth and uniform surface finish, with no weak points or potential areas for leakage. Seamless pipes are generally considered to have higher strength and pressure ratings, making them suitable for high-pressure applications such as oil and gas pipelines, refineries, and petrochemical plants. On the other hand, ERW stainless steel pipes are manufactured by rolling a strip of stainless steel into a tube shape and welding the edges together using a high-frequency electric current. This welding process creates a strong bond between the edges, resulting in a welded seam running along the length of the pipe. ERW pipes are more cost-effective compared to seamless pipes and are commonly used in applications where high pressure is not a major concern, such as plumbing, structural applications, and low-pressure fluid transport. In terms of physical characteristics, seamless pipes have a smoother interior surface, which allows for better flow properties and reduces the risk of corrosion or scaling. ERW pipes, due to the welding process, may have a slightly rougher interior surface, but this does not significantly impact their performance in most applications. It is important to consider the specific requirements of your project when choosing between seamless and ERW stainless steel pipes. Factors such as pressure ratings, corrosion resistance, cost, and intended use should all be taken into account to ensure the most suitable option is selected.

- Q: Can stainless steel pipes be engraved?

- Yes, stainless steel pipes can be engraved. Engraving is a process that involves etching or carving designs, patterns, or text onto the surface of an object. Stainless steel is a versatile material that can be engraved using various methods, such as laser engraving, rotary engraving, or hand engraving. Laser engraving is particularly popular for stainless steel pipes as it provides precise and permanent markings. The engraved design or text can enhance the aesthetic appeal of the pipes and also serve functional purposes, such as identification or branding. However, it is important to note that the depth and quality of the engraving may vary depending on the type and grade of stainless steel used.

- Q: Can stainless steel pipes be wrapped with tape?

- Yes, stainless steel pipes can be wrapped with tape. However, it is important to use the appropriate type of tape designed specifically for stainless steel. This is because stainless steel pipes are often used in industrial and high-temperature applications, and ordinary tapes may not be able to withstand the extreme conditions. Stainless steel pipe tapes are typically made of materials like stainless steel foil or aluminum foil with a heat-resistant adhesive to ensure long-lasting durability and resistance to corrosion. These tapes can be used for various purposes such as insulation, sealing, or protection against abrasion. It is always recommended to consult the manufacturer's guidelines or seek professional advice before applying any tape to stainless steel pipes to ensure proper installation and avoid any potential issues.

- Q: Are stainless steel pipes suitable for marine environments?

- Yes, stainless steel pipes are highly suitable for marine environments. They have excellent corrosion resistance properties, which make them resistant to the harsh conditions found in marine settings such as saltwater, high humidity, and exposure to various chemicals. Stainless steel pipes are durable, long-lasting, and can withstand the corrosive effects of seawater, making them an ideal choice for marine applications.

- Q: Can stainless steel pipes be used for underground gas lines?

- Yes, stainless steel pipes can be used for underground gas lines. Stainless steel is highly resistant to corrosion and can withstand extreme temperatures, making it a suitable material for underground gas distribution systems. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a reliable choice for underground gas line installations.

- Q: How are stainless steel pipes measured?

- Two main parameters are used to measure stainless steel pipes: outer diameter (OD) and wall thickness. The outer diameter corresponds to the pipe's outer circumference, while the wall thickness indicates the thickness of the pipe's walls. These measurements are crucial for determining the pipe's suitability for a particular application and ensuring compatibility with fittings and connectors. Stainless steel pipe dimensions are typically stated in millimeters or inches, and they may vary depending on project requirements or industry standards. Precise measurement is essential to guarantee the correct fitting and functionality of stainless steel pipes in diverse applications, including plumbing, construction, or industrial processes.

- Q: Can stainless steel pipes be painted or coated?

- Yes, stainless steel pipes can be painted or coated. However, it is essential to choose the appropriate paint or coating that is specifically designed for stainless steel to ensure proper adhesion and long-term durability. Additionally, the surface of the stainless steel pipes should be thoroughly cleaned and prepared before applying any paint or coating.

Send your message to us

Stainless Steel 304 sheet for wholesale only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords