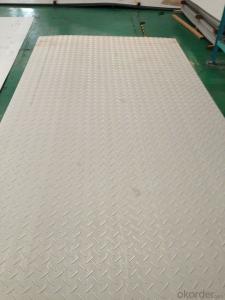

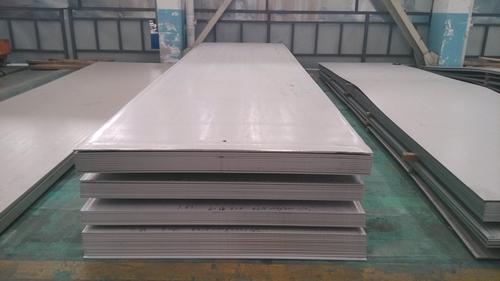

Stainless Steel 304 sheet for exporting only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: What is the difference between 304Ti and 316Ti stainless steel pipes?

- 304Ti and 316Ti are two types of stainless steel pipes that differ in several key aspects. The primary distinction between them lies in their chemical composition. 304Ti is a variant of the 304 stainless steel grade, whereas 316Ti is a variant of the 316 stainless steel grade. A significant difference between the two is the presence of molybdenum in 316Ti, which is absent in 304Ti. Molybdenum enhances the corrosion resistance of stainless steel, making 316Ti more resistant to pitting and crevice corrosion in chloride-containing environments like marine or coastal areas. This characteristic makes 316Ti the preferred choice for applications where exposure to corrosive elements is a concern. Furthermore, 316Ti has a lower carbon content compared to 304Ti, which improves its resistance to sensitization and intergranular corrosion. Sensitization occurs when stainless steel is exposed to high temperatures, leading to the formation of chromium carbides that can reduce the material's corrosion resistance. By reducing the carbon content, 316Ti minimizes the risk of sensitization and maintains its corrosion resistance even under high-temperature conditions. In terms of mechanical properties, 316Ti generally exhibits higher tensile strength and yield strength than 304Ti, making it more suitable for applications requiring greater strength and durability. However, it is essential to note that both grades of stainless steel pipes possess excellent strength and toughness. To summarize, the main differences between 304Ti and 316Ti stainless steel pipes lie in their chemical compositions and resulting corrosion resistance. 316Ti offers superior corrosion resistance in chloride-containing environments and better resistance to sensitization and intergranular corrosion. However, the choice between the two grades ultimately depends on specific application requirements and environmental factors.

- Q: Can stainless steel pipes be insulated with Teflon?

- No, stainless steel pipes cannot be insulated with Teflon. Teflon is not suitable for insulation purposes as it is a non-conductive material and lacks the necessary thermal properties to effectively insulate pipes.

- Q: Can stainless steel pipes be magnetized?

- Stainless steel pipes have the potential to be magnetized to some degree, although they are generally considered non-magnetic unlike ferromagnetic substances like iron or nickel. This is due to the presence of a substantial amount of chromium, which creates a protective oxide layer on the steel's surface, making it resistant to magnetization. Nevertheless, stainless steel can still exhibit a slight attraction to a magnet, particularly if it has undergone specific processes like cold working or welding. These procedures can alter the steel's crystalline structure, enabling it to acquire a slight magnetic quality. It is important to emphasize that the magnetic force in stainless steel pipes is relatively weak and will not possess the same level of magnetism or ability to attract other magnetic objects as ferromagnetic materials would.

- Q: Can stainless steel pipes be used in the agriculture industry?

- Indeed, the agriculture industry can employ stainless steel pipes. As a remarkably sturdy and corrosion-resistant material, stainless steel proves ideal for diverse agricultural applications. For instance, stainless steel pipes find frequent use in agricultural fields for irrigation systems, water distribution networks, and drainage systems. Their resistance to rust, corrosion, and chemical harm guarantees a prolonged lifespan despite the harsh agricultural environment. Moreover, stainless steel pipes offer convenience in terms of cleaning and maintenance, rendering them a favored option for transporting an array of liquids and gases within the agriculture industry.

- Q: Are stainless steel pipes fire-resistant?

- Indeed, fire resistance is a characteristic possessed by stainless steel pipes. Renowned for its elevated melting point and exceptional fire resistance, stainless steel is a secure material choice for numerous purposes, including the construction of pipes. With its incapability to readily ignite or facilitate the expansion of flames, stainless steel ensures safety in various applications. Moreover, stainless steel pipes exhibit remarkable durability and strength even when exposed to high temperatures, assuring an additional layer of safety in environments susceptible to fires.

- Q: How are stainless steel pipes joined or connected?

- Various methods are employed to join or connect stainless steel pipes, depending on the specific application and requirements. Welding is a commonly used technique, in which the pipes are fused together using heat to establish a robust and enduring connection. This can be accomplished through different welding methods, including TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. Another approach involves threading the ends of the pipes and subsequently fastening them together using pipe fittings. This method is particularly favored for smaller diameter pipes or situations that necessitate disassembly. Additionally, compression fittings can also be utilized to connect stainless steel pipes. This involves the use of a compression ring or ferrule to create a tight seal between the pipes. This method is often employed when connecting pipes with larger diameters or when frequent disassembly is required. Ultimately, the choice of joining or connecting method for stainless steel pipes relies on the specific project requirements, such as pipe size, pressure, temperature, and the need for disassembly.

- Q: Can stainless steel pipes be threaded with NPT threads?

- Yes, stainless steel pipes can be threaded with NPT (National Pipe Thread) threads.

- Q: What are the different types of stainless steel pipe reducers?

- On the market, there exists a variety of stainless steel pipe reducers. Some commonly found types are: 1. Concentric Reducers: These reducers possess a symmetrical design and facilitate the connection of pipes with varying diameters while maintaining a straight flow. They are primarily employed when a gradual reduction in pipe size is necessary. 2. Eccentric Reducers: In contrast to concentric reducers, eccentric reducers feature an offset design. They are used to connect pipes with different diameters while altering the centerline of the pipe. This type of reducer is often utilized when preventing the entrapment of air or fluids within the piping system is necessary. 3. Swage Reducers: Swage reducers, a unique kind of reducer, are employed to connect pipes with different diameters, especially in high-pressure applications. They find common usage in industries such as oil and gas, as well as chemical plants, where a smooth transition between various pipe sizes is required. 4. Threaded Reducers: These reducers possess threaded ends, enabling them to be screwed onto pipes. They are commonly employed in applications where a secure and leak-proof connection is imperative, such as in plumbing or gas systems. 5. Welded Reducers: Welded reducers are specifically designed to be welded onto pipes. They are frequently utilized in applications where strength and durability are essential, such as in industrial settings or high-pressure systems. 6. Socket Weld Reducers: Similar to welded reducers, socket weld reducers have a socket at one end, making it simple to connect them to pipes using a socket weld joint. They are commonly employed in applications where a robust and reliable joint is necessary. To ensure a proper and efficient connection between pipes of different sizes, it is crucial to select the appropriate type of stainless steel pipe reducer based on the specific application and requirements.

- Q: Are stainless steel pipes suitable for underground water supply?

- Yes, stainless steel pipes are suitable for underground water supply. They are highly resistant to corrosion, have a long lifespan, and are capable of withstanding high pressure. Additionally, stainless steel pipes maintain the quality and purity of the water, making them a reliable choice for underground water supply systems.

- Q: How do stainless steel pipes compare to concrete pipes?

- Stainless steel pipes offer several advantages over concrete pipes. Firstly, stainless steel pipes have a higher strength-to-weight ratio, making them lighter and easier to handle during installation. They are also more resistant to corrosion and have a longer lifespan than concrete pipes. Additionally, stainless steel pipes have smoother inner surfaces, enabling better flow rates and reducing the likelihood of blockages. Lastly, stainless steel pipes are more flexible and can withstand temperature variations, making them suitable for a wider range of applications compared to concrete pipes.

Send your message to us

Stainless Steel 304 sheet for exporting only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords