HRB400 stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering hrb400 stainless steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

HRB400 stainless steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

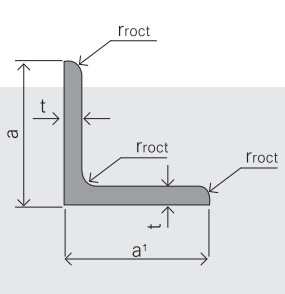

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Material details:

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel angles be used as lintels?

- Yes, steel angles can be used as lintels. Steel angles are commonly used in construction as lintels due to their strength and durability. Lintels are structural elements that support the weight of the wall above an opening, such as a door or window. Steel angles are especially suitable for this purpose because they can bear heavy loads and provide excellent structural support. They are often used in masonry construction to create a strong and stable lintel. Additionally, steel angles can be easily customized to fit specific dimensions, making them a flexible choice for lintel applications.

- Q: How do you determine the torsional stiffness of a steel angle?

- To determine the torsional stiffness of a steel angle, you need to consider its geometry and material properties. First, you should calculate the polar moment of inertia (J) of the steel angle. The polar moment of inertia represents a shape's resistance to torsion and is calculated by summing the products of the differential area elements and their distances squared from the axis of rotation. For a steel angle, you can use standard formulas or reference tables to determine the polar moment of inertia. Next, you need to determine the material properties of the steel angle, specifically its modulus of rigidity (G). The modulus of rigidity measures a material's resistance to deformation under shear stress. This value is typically provided by the steel manufacturer or can be obtained from material property databases. Once you have calculated the polar moment of inertia and obtained the modulus of rigidity, you can determine the torsional stiffness (K) using the formula K = G * J. The torsional stiffness represents the ability of the steel angle to resist twisting or torsional deformation when subjected to a torque. It is important to note that the torsional stiffness of a steel angle can vary depending on factors such as the angle's size, shape, and the specific steel alloy used. Therefore, it is recommended to consult relevant design codes or engineering references to ensure accurate calculations and consider any additional factors that may affect the torsional stiffness.

- Q: How do you determine the required angle thickness for a specific application?

- To determine the necessary thickness of an angle for a particular application, multiple factors must be taken into account. First and foremost, one must understand the load or force that will be placed on the angle. This can be achieved by analyzing the specific application and estimating the weight or pressure that will be exerted on the angle. Next, the material of the angle must be considered. Different materials possess varying strength properties, and their ability to withstand the applied load will differ accordingly. It is crucial to select a material that possesses the necessary strength and durability for the application at hand. Alongside this, the length of the angle and the distance between its supports should also be considered. Longer angles or greater distances between supports may necessitate thicker angles to prevent buckling or bending when subjected to the applied load. Furthermore, environmental factors like temperature, humidity, or corrosive substances may impact the required thickness of the angle. For example, in corrosive environments, a thicker angle may be essential to ensure its longevity and structural integrity. Finally, it is imperative to consult applicable building codes, regulations, or industry standards to ensure compliance and safety. These guidelines often provide specific recommendations or requirements for angle thickness based on the intended application. In conclusion, determining the required angle thickness for a specific application entails analyzing the load, material strength, length, support distance, environmental factors, and relevant regulations. Proper consideration of these factors will help guarantee that the angle can withstand the applied load and provide a safe and durable solution for the given application.

- Q: Are steel angles available in different finishes?

- Yes, steel angles are available in different finishes. Steel angles can be finished with various coatings or treatments to enhance their appearance or provide additional protection against corrosion. Some common finishes for steel angles include galvanized, painted, or powder-coated finishes. Galvanized steel angles are coated with a layer of zinc to prevent rusting, while painted or powder-coated finishes offer a wide range of color options for aesthetic purposes. Additionally, steel angles can also be left unfinished, which gives them a raw, industrial look. The availability of different finishes for steel angles allows for greater versatility in their applications, as they can be tailored to meet specific functional and aesthetic requirements.

- Q: What is the typical thickness of the base of a steel angle?

- The base thickness of a steel angle can vary depending on its specific application and requirements. Typically, the base thickness of a steel angle ranges from 1/8 inch to 3/8 inch. It is worth mentioning that this range is not comprehensive, and there may be instances where the base thickness deviates from these parameters. Elements such as the steel angle's size, load-bearing capacity, and intended purpose will impact the necessary base thickness for a particular project or structure. As a result, consulting engineering specifications or seeking professional guidance is crucial in determining the suitable base thickness for a steel angle in a specific application.

- Q: How are steel angles measured?

- Steel angles are measured using two main dimensions: the length of each leg and the thickness of the material. The length of each leg refers to the distance from the intersection point of the two legs to the end of each leg. This measurement is usually expressed in inches or millimeters. The thickness of the material, also known as the gauge, is the measurement of the width of the steel angle. It is typically expressed in fractions of an inch or in millimeters. To provide a comprehensive measurement, steel angles are often described using a combination of these two dimensions. For example, a common specification could be "2 x 2 x 1/4," indicating that the steel angle has legs measuring 2 inches in length, a thickness of 1/4 inch, and both legs are equal in length. It is important to note that steel angles can be measured differently depending on the specific industry or region. Some industries may use metric measurements, while others may use imperial measurements. Therefore, it is always advisable to verify the measuring standards used in a particular context to ensure accurate understanding and communication.

- Q: Can steel angles be used for framing or supporting partitions?

- Yes, steel angles can be used for framing or supporting partitions. Steel angles are commonly used in construction due to their strength and durability. They provide excellent support and stability, making them suitable for framing or supporting partitions in various structures.

- Q: What are the design standards for steel angles?

- The design standards for steel angles depend on the specific application and industry requirements. However, there are some general design standards that are commonly followed in the construction and engineering fields. One important aspect is the dimensional and mechanical properties of the steel angles. These properties include the angle's size, thickness, length, and weight. The dimensions are typically specified in millimeters or inches, and the mechanical properties determine the angle's strength and load-bearing capacity. In terms of shape, steel angles are typically L-shaped with equal or unequal legs. The equal-legged angles have two legs of the same length, while unequal-legged angles have two legs of different lengths. The angle's shape and geometry play a crucial role in determining its structural integrity and stability. Another important consideration is the material specification for the steel angles. The material used for fabrication should meet certain standards, such as the American Society for Testing and Materials (ASTM) specifications, to ensure the required strength, ductility, and toughness. Commonly used materials for steel angles include carbon steel, stainless steel, and alloy steel. The design standards for steel angles also include guidelines for connection details. These details specify the method of connecting the angles to other structural members, such as beams, columns, or plates. The connection details ensure proper load transfer and structural stability, and they may involve welding, bolting, or other mechanical fastening methods. Additionally, design standards may include guidelines for the design of steel angle members subjected to specific loads, such as axial compression, bending, or shear. These guidelines provide formulas, charts, and design tables that allow engineers to calculate the required size and strength of the angle based on the applied loads and other factors. Overall, the design standards for steel angles ensure that these structural members meet specific requirements in terms of dimensions, material properties, shape, and connection details. These standards help ensure the safety, reliability, and performance of steel angles in various applications, ranging from building construction to industrial machinery.

- Q: Can steel angles be used for load-bearing walls?

- Yes, steel angles can be used for load-bearing walls. Steel angles are commonly used in construction as a structural element to provide support and stability. They are often used to reinforce load-bearing walls by adding strength and rigidity. Steel angles can be used to distribute the weight of a load evenly, making them suitable for load-bearing applications. However, it is important to ensure that the steel angles are appropriately designed and installed to meet the specific load requirements of the wall. Consulting with a structural engineer or construction professional is recommended to ensure the proper use of steel angles for load-bearing walls.

- Q: Can steel angles be used in historical or heritage restoration projects?

- Yes, steel angles can be used in historical or heritage restoration projects. Steel angles are versatile and can be used in a variety of applications, including structural support, reinforcing, and decorative detailing. They can be fabricated to match the original design and materials used in historical structures, ensuring a seamless integration with the existing architecture. Steel angles offer several advantages, such as strength, durability, and resistance to corrosion, which can be particularly beneficial in restoration projects where the goal is to preserve the historical integrity of the structure while improving its structural stability and longevity. Additionally, steel angles can be customized and fabricated to meet specific project requirements, making them suitable for a wide range of restoration applications.

Send your message to us

HRB400 stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords