Spring Steel Round Bars Grade 55cr3

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Basic Information:

Material | ASTM SAE 5155 | ||

Chemical Composition | Mechanical Properties(In Quenched & Tempered State) | ||

C | 0.52-0.60 | Tensile strength(MPA) | 1078 |

Si | 0.17-0.37 | Yield strength (MPA) | 1225 |

Mn | 0.65-0.95 | Elongation(δ5/%) | 9 |

Cr | 0.65-0.95 | Reduction in Area (ψ/%) | 20 |

Mo | - | Impact (J) | - |

P | ≤0.035 |

Hardness |

- |

S | ≤0..035 | ||

Cu | 0.25 | ||

Ni | 0.35 | ||

Product Sales Information:

Material | bearing Steel round bar |

Size | Diameter:20mm-1000mm Length:500mm-6000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled,cold drawn,forged |

Surface require | Black,grinding,bright,polish |

Heat treatment | Quenched,Tempered,annealed |

Packing | seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | In 10-50 days |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

MOQ | 1 Ton |

FAQ of Spring Steel Round Bars:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard.Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

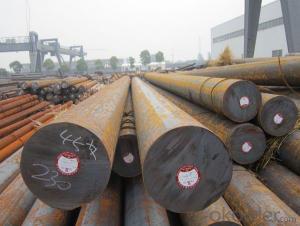

Spring Steel Round Bars Images

- Q: How is precipitation-hardening steel used in aerospace applications?

- Precipitation-hardening steel is commonly used in aerospace applications due to its exceptional strength-to-weight ratio and excellent corrosion resistance. It is extensively used in critical components such as aircraft structural parts, landing gear, engine components, and fasteners. The precipitation hardening process involves heating and cooling the steel to create a fine dispersion of precipitates, which significantly enhances its mechanical properties. This steel's high strength allows for the construction of lighter and more fuel-efficient aircraft, while its corrosion resistance prolongs the lifespan of aerospace components, ensuring safe and reliable operation.

- Q: How does special steel contribute to the energy storage sector?

- Special steel plays a crucial role in the energy storage sector by providing essential components for various energy storage systems. One significant application of special steel is in the manufacturing of batteries, which are essential for storing energy in various forms. Special steel is ideal for battery casings and frames due to its high strength, excellent corrosion resistance, and durability. Battery casings made from special steel can withstand high pressures and protect the internal components from external impacts, ensuring the safety and reliability of the entire energy storage system. Furthermore, special steel is utilized in the production of electrodes, a critical component of batteries. Electrodes require materials that can efficiently conduct electricity while enduring repeated charge and discharge cycles. Special steel, such as stainless steel, possesses excellent electrical conductivity and can withstand the demanding conditions within batteries, making it an ideal choice for electrode manufacturing. Additionally, special steel is employed in the construction of infrastructure for energy storage systems. Steel structures are used to support large-scale energy storage devices like pumped hydro storage facilities and compressed air energy storage systems. These structures must be strong, durable, and resistant to environmental conditions. Special steel provides the necessary strength and corrosion resistance to ensure the longevity and reliability of these energy storage infrastructure projects. In summary, special steel contributes significantly to the energy storage sector by providing essential components for batteries, such as casings and electrodes. It also plays a vital role in the construction of infrastructure for energy storage systems. With its exceptional properties, special steel enhances the safety, efficiency, and durability of energy storage technologies, thereby facilitating the growth and advancement of the renewable energy sector as a whole.

- Q: How does special steel contribute to the efficiency of automotive engines?

- Special steel plays a vital role in enhancing the efficiency of automotive engines in various ways. To begin with, it provides exceptional strength and durability, allowing for the production of lighter and more compact engine components. This reduction in weight contributes to increased fuel efficiency, as the engine requires less effort to propel the vehicle, resulting in improved performance and reduced emissions. Moreover, special steel possesses excellent properties of heat resistance and thermal conductivity. These characteristics are particularly important in automotive engines, which generate significant heat during operation. By incorporating special steel into critical engine parts such as cylinder heads, valves, and pistons, manufacturers can effectively manage the generated heat, preventing engine overheating and ensuring optimal performance. Additionally, special steel exhibits high resistance to wear, corrosion, and fatigue, making it an ideal choice for components exposed to high levels of stress and friction in automotive engines. This enhanced durability translates into a longer engine lifespan, reduced maintenance costs, and improved reliability. Furthermore, the use of special steel allows for the production of more precise and intricate engine designs. Its superior machinability enables the creation of complex shapes and structures, optimizing airflow and combustion within the engine. This leads to improved fuel combustion efficiency, power output, and overall engine performance. In conclusion, the contribution of special steel to the efficiency of automotive engines cannot be underestimated. Its properties of strength, heat resistance, durability, and machinability enable the production of lighter, more durable, and high-performing engine components. By integrating special steel into automotive engines, manufacturers can achieve enhanced fuel efficiency, reduced emissions, longer engine lifespan, and improved overall performance.

- Q: How does special steel contribute to the tool manufacturing industry?

- Special steel plays a crucial role in the tool manufacturing industry as it offers several advantages that enhance the quality, performance, and durability of tools. Firstly, special steel is known for its exceptional strength and toughness, which makes it ideal for manufacturing high-quality tools that can withstand heavy usage and extreme conditions. In addition to strength, special steel also offers excellent wear resistance. Tools made from special steel can retain their sharpness and cutting edge for a longer period, reducing the need for frequent re-sharpening or replacement. This not only saves time and effort but also increases productivity in various industries that heavily rely on tools, such as construction, automotive, and aerospace. Moreover, special steel can be heat-treated to achieve specific properties, such as hardness, which is vital for tools like drills, saws, and blades. This heat treatment process allows manufacturers to tailor the steel's characteristics to meet the specific requirements of different tools, ensuring optimal performance and effectiveness. Special steel also provides corrosion resistance, an essential feature for tools that may be exposed to moisture, chemicals, or harsh environments. By preventing rust and corrosion, special steel helps to prolong the lifespan of tools, reducing maintenance costs and ensuring their reliable performance over time. Furthermore, the versatility of special steel allows manufacturers to create tools with complex shapes and designs. This flexibility opens up opportunities for innovation and the development of specialized tools that cater to unique applications and industries. Special steel can be easily machined, welded, and formed into various tool designs, enabling manufacturers to create efficient and ergonomic tools that offer improved handling and user comfort. In summary, special steel significantly contributes to the tool manufacturing industry by providing strength, wear resistance, heat treatability, corrosion resistance, and versatility. These properties enable the production of high-quality tools that are durable, reliable, and efficient, meeting the demands of diverse industries and enhancing productivity.

- Q: What are the main advantages of using special steel in the food processing industry?

- The main advantages of using special steel in the food processing industry are its high corrosion resistance, durability, and hygienic properties. Special steel is resistant to rust and corrosion, ensuring that it does not contaminate the food being processed. It also possesses excellent strength and durability, making it suitable for handling heavy loads and withstanding harsh operating conditions. Furthermore, special steel is easy to clean and maintain, promoting a higher level of hygiene in food processing facilities.

- Q: How does special steel perform in corrosive environments?

- The purpose of special steel is to excel in corrosive environments. This is achieved by incorporating a greater amount of alloying elements, like chromium, which generates a safeguarding oxide layer on the steel's surface. By doing so, the steel is shielded from direct contact with the corrosive elements present in the environment. In addition, special steel may contain other alloying elements such as molybdenum, nickel, or copper, which further enhance its ability to resist corrosion. These elements contribute to the steel's capacity to withstand various types of corrosion, including pitting, crevice corrosion, and stress corrosion cracking, which are commonly observed in corrosive environments. Moreover, special steel often undergoes treatments with diverse surface coatings or finishes that offer additional defense against corrosion. These coatings encompass materials like zinc, epoxy, or polymers, which establish an extra barrier between the steel and the corrosive elements. To summarize, special steel delivers exceptional performance in corrosive environments due to its abundant alloying elements, protective oxide layer, and supplementary surface coatings. It provides remarkable resistance against different forms of corrosion and guarantees the durability and dependability of structures or equipment operating in such environments.

- Q: How does special steel contribute to the manufacturing of consumer goods?

- Consumer goods manufacturing greatly relies on special steel to enhance the durability, strength, and performance of various products. This type of steel is specifically engineered with unique properties and alloys to meet the demanding standards of the industry. One way in which special steel significantly contributes to consumer goods manufacturing is through its exceptional strength and durability. It forms a solid foundation for products that need to endure heavy use, such as kitchen appliances, power tools, and automotive components. The strength of special steel guarantees that these products can withstand daily wear and tear, resulting in longer lifespans and reduced maintenance costs for consumers. Additionally, the corrosion resistance properties of special steel make it an ideal material for consumer goods exposed to harsh environments or moisture. This is particularly crucial for products like kitchen utensils, cutlery, and bathroom fixtures, as they frequently come into contact with water or corrosive substances. By incorporating special steel, manufacturers can ensure that their products remain free from rust and maintain their aesthetic appeal over time. Furthermore, special steel offers enhanced performance capabilities. For example, it can be utilized in the manufacturing of consumer goods requiring high heat resistance, such as cooking appliances and automotive engine components. Special steel's ability to withstand extreme temperatures without deforming or losing its properties makes it an essential material for these applications. Moreover, the versatility of special steel allows it to be customized to meet specific consumer needs. Manufacturers have a wide range of special steel alloys with varying characteristics to choose from, enabling them to optimize the performance of their products. This flexibility enables the production of personalized consumer goods that meet specific requirements, whether it involves lightweight materials for portable electronics or impact-resistant components for sporting equipment. Overall, special steel plays a vital role in consumer goods manufacturing by providing strength, durability, corrosion resistance, and enhanced performance. Its unique properties contribute to the production of high-quality products that can withstand heavy use, offer extended lifespans, and ensure customer satisfaction.

- Q: How does special steel contribute to the aerospace racing aftermarket industry?

- Special steel plays a significant role in enhancing the performance, durability, and safety of aircraft and racing vehicles within the aerospace racing aftermarket industry. Its importance cannot be overstated. To start with, critical engine components like turbine blades, compressor discs, and shafts are manufactured using special steel. These components must withstand extreme temperatures, pressures, and mechanical stress during operation. Nickel-based superalloys, which are a type of special steel alloy, provide excellent heat resistance, high strength, and exceptional corrosion resistance. This ensures that the engine systems perform at their best and are reliable. Additionally, special steel is essential in constructing airframe structures. Titanium alloys, which are lightweight yet possess high-strength properties, are crucial in reducing the overall weight of aircraft and racing vehicles. This reduction in weight leads to improved fuel efficiency, increased speed, and better handling capabilities. Therefore, special steel is an indispensable material in the aerospace racing aftermarket. Furthermore, special steel is utilized in the production of landing gear systems, which are vital for safe takeoffs, landings, and overall maneuverability. The landing gear must endure immense forces and shock loads during these operations. Special steel alloys such as chromium-molybdenum steel offer exceptional toughness, fatigue resistance, and impact strength. This ensures the landing gear's reliability and longevity. Moreover, special steel plays a crucial role in manufacturing aerospace racing aftermarket components like fasteners, bearings, and gears. These components require high strength, wear resistance, and dimensional stability to withstand the demanding conditions of racing and provide optimal performance. Special steel alloys like stainless steel and tool steel possess these desirable properties, ensuring the longevity and reliability of these crucial components. To sum up, special steel's exceptional properties, including high strength, heat resistance, corrosion resistance, and fatigue resistance, enable the production of reliable, efficient, and high-performance aircraft and racing vehicles within the aerospace racing aftermarket industry. Without special steel, the industry would be unable to achieve the level of advanced technology, speed, and safety that it currently enjoys.

- Q: What is the tensile strength of special steel?

- The tensile strength of special steel can vary depending on the specific alloy and manufacturing process, but it is generally much higher than that of regular steel.

- Q: How does special steel perform in corrosion fatigue conditions?

- Special steel is renowned for its exceptional performance under corrosion fatigue conditions. Corrosion fatigue refers to the detrimental effect of both corrosion and cyclic loading on materials' mechanical properties over time. However, special steel is specifically engineered and alloyed to withstand corrosion and maintain its structural integrity in these challenging circumstances. The addition of alloying elements like chromium, nickel, and molybdenum enables special steel to achieve high corrosion resistance. These elements create a protective oxide layer on the steel's surface, acting as a barrier against corrosive agents. This layer effectively prevents the infiltration of moisture, oxygen, and other corrosive substances, reducing the likelihood of corrosion initiation and propagation. Moreover, special steel exhibits remarkable fatigue strength, enabling it to endure cyclic loading without premature failure. Its unique microstructure, typically martensitic or austenitic, provides superior mechanical properties and resistance to fatigue crack initiation and propagation. Consequently, the material can withstand repeated loading cycles without compromising its structural integrity. Additionally, special steel possesses good ductility and toughness, essential properties in corrosion fatigue conditions. These characteristics allow the material to effectively absorb and distribute stress, preventing localized stress concentrations that may result in crack formation and propagation. In conclusion, special steel's exceptional performance under corrosion fatigue conditions can be attributed to its high corrosion resistance, fatigue strength, ductility, and toughness. These properties make it an ideal choice for applications involving cyclic loading and corrosive environments, such as offshore structures, marine equipment, and oil and gas pipelines.

Send your message to us

Spring Steel Round Bars Grade 55cr3

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords