55Cr3 Alloy Flat Spring Steel Bars for Leaf Springs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

55Cr3 Alloy Flat Spring Steel Bars for Leaf Springs

Product Information:

Certificate:ISO 9001:2008

International Standard:GB DIN JIS AISI ASTM SAE

Angle:Right-Angle & Double Angle

Technique:Oil Heat Treatment & Hot Rolled

Surface:Grooved / Plain-Smoothed

Quenchant:Oil /Water

Quenching Temperature:800°C~1000°C

Stressing Temperature:480°C~560°C

Raw Material;Concast Steel Billets (150×150mm)

OEM:Material Composition Offered By Customers

Allpication:Automotive suspension leaf springs

Rotary tools and Blades

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

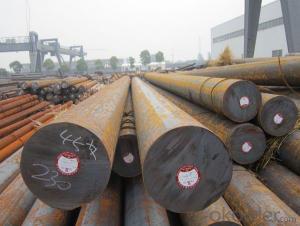

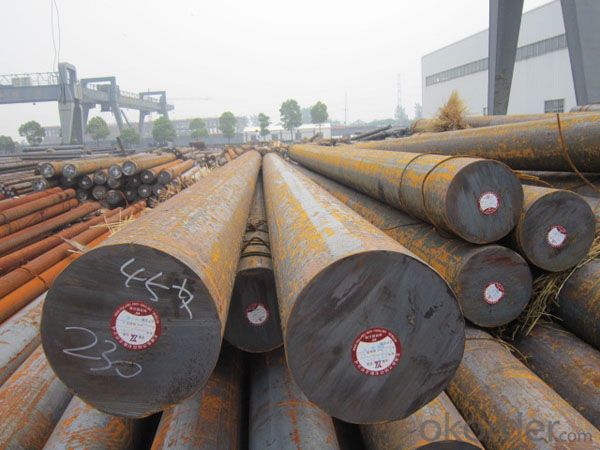

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: What are the common surface treatments applied to special steel?

- Some common surface treatments applied to special steel include galvanizing, powder coating, electroplating, and heat treatments such as case hardening. These treatments help improve the corrosion resistance, hardness, and appearance of the steel, making it suitable for various applications in industries like construction, automotive, and aerospace.

- Q: What are the requirements for special steel used in military applications?

- The requirements for special steel used in military applications typically include high strength, toughness, and durability to withstand extreme conditions and heavy impact. It should have excellent resistance to corrosion, wear, and fatigue to ensure long-term performance. The steel must also possess good weldability and machinability for ease of fabrication and maintenance. Additionally, it should meet stringent specifications and standards set by military organizations to ensure reliability, safety, and compatibility with other materials and systems.

- Q: Can special steel be used in the production of artistic sculptures?

- Yes, special steel can definitely be used in the production of artistic sculptures. Special steel, which refers to steel alloys that have been specifically designed and manufactured for particular applications, offers a wide range of advantages that make it suitable for creating sculptures. Firstly, special steel alloys provide exceptional strength and durability, allowing sculptors to create large and intricate structures that can withstand external forces and environmental conditions. This strength and resilience is crucial, especially for outdoor sculptures that are exposed to weather elements such as rain, wind, and extreme temperatures. Additionally, special steel alloys offer versatility in terms of shaping and forming. They can be easily molded and manipulated into various shapes and sizes, which allows artists to bring their creative visions to life. Sculptors can utilize different techniques such as welding, cutting, and bending to shape the steel into their desired forms, enabling them to create unique and captivating sculptures. Moreover, special steel alloys can be finished in various ways, such as polishing, painting, or coating, to enhance their aesthetic appeal. This allows artists to add different textures, colors, and surface finishes to their sculptures, further enhancing their artistic value. Furthermore, special steel alloys can also provide resistance to corrosion, which is particularly important for sculptures that are placed in outdoor or humid environments. This corrosion resistance ensures that the sculptures retain their visual appeal and structural integrity over time, reducing the need for frequent maintenance and repairs. In conclusion, special steel offers a wide range of advantages that make it an excellent choice for the production of artistic sculptures. Its strength, versatility, aesthetic appeal, and resistance to corrosion provide artists with the necessary tools to create visually stunning and durable sculptures that can be enjoyed for years to come.

- Q: How does special steel compare to other materials like aluminum or titanium?

- Special steel, such as stainless steel or tool steel, offers several advantages over materials like aluminum or titanium. Firstly, special steel generally exhibits higher strength and hardness, making it ideal for applications requiring durability and resistance to wear. Secondly, special steel possesses excellent thermal conductivity, allowing it to dissipate heat more efficiently compared to aluminum or titanium. Additionally, special steel is often more cost-effective and readily available in comparison to titanium. However, aluminum and titanium are known for their lightweight properties, making them preferable for applications where weight reduction is crucial. Ultimately, the choice between special steel, aluminum, or titanium depends on the specific requirements and constraints of the intended application.

- Q: How does special steel contribute to the fatigue resistance of products?

- Special steel contributes to the fatigue resistance of products through its unique properties and manufacturing processes. Firstly, special steel is specifically designed and engineered to have enhanced strength and durability, making it highly resistant to fatigue. This is achieved by incorporating alloying elements such as chromium, nickel, molybdenum, and vanadium, which improve the material's ability to withstand cyclic loading and stress. In addition, special steel undergoes rigorous heat treatment processes, such as quenching and tempering, to further enhance its fatigue resistance. These processes help refine the microstructure of the steel, resulting in a more uniform and fine-grained material. This, in turn, improves the steel's resistance to crack initiation and propagation, which are key factors leading to fatigue failure. Moreover, special steel often undergoes specialized surface treatments, such as shot peening or nitriding, which introduce compressive residual stresses on the surface of the material. These compressive stresses act as a barrier against crack formation and growth, significantly enhancing the fatigue resistance of the product. Additionally, special steel can be manufactured with specific grain orientations, such as through the use of directional solidification techniques. This allows for the alignment of grains along the primary loading direction, improving the material's fatigue performance by reducing the likelihood of crack initiation at grain boundaries. Overall, the unique properties and manufacturing processes associated with special steel contribute to its exceptional fatigue resistance. Its enhanced strength, refined microstructure, specialized surface treatments, and tailored grain orientations all work together to prolong the lifespan and reliability of products, making special steel a preferred choice in various industries where fatigue failure is a concern.

- Q: How does special steel contribute to the transportation equipment industry?

- The transportation equipment industry relies heavily on special steel for several reasons. To begin with, special steel alloys are utilized in the manufacturing of various vehicle components, including engine parts, suspension systems, and transmission components. These alloys possess exceptional strength, durability, and resistance to corrosion, ensuring that vehicles can withstand harsh operating conditions and have a longer lifespan. Furthermore, special steel is crucial in the production of railway tracks and infrastructure, which greatly contributes to the efficiency and safety of transportation systems. The high-quality steel used in railway tracks ensures stability, reduces maintenance requirements, and improves overall railway performance. Moreover, special steel is employed in the manufacturing of aircraft components, where precision, reliability, and lightness are of utmost importance. Steel alloys with outstanding mechanical properties are utilized in critical parts like landing gear, engine components, and structural elements, guaranteeing the safety and efficiency of air transport. Additionally, special steel plays a vital role in shipbuilding and the production of marine vessels. The use of corrosion-resistant steel alloys in shipbuilding helps to prevent rusting, extending the lifespan of vessels and reducing maintenance costs. Moreover, certain steel alloys with a high strength-to-weight ratio allow for the construction of lighter ships, resulting in increased fuel efficiency and reduced emissions. In summary, special steel's exceptional properties and characteristics make it an essential material in the transportation equipment industry. It enhances the performance, safety, and durability of vehicles, railways, aircraft, and ships, ultimately improving the efficiency and reliability of transportation systems.

- Q: How does special steel resist oxidation?

- Special steel resists oxidation due to the presence of alloying elements, such as chromium, that form a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen from reaching the underlying steel and thus inhibiting the oxidation process.

- Q: What are the different methods of surface grinding for special steel?

- There are several different methods of surface grinding that can be used for special steel. Here are some of the most commonly utilized methods: 1. Blanchard Grinding: This method involves using a rotary table and a grinding wheel to remove material from the surface of the steel. The grinding wheel is typically made of abrasive particles bonded together in a matrix and rotates at a high speed. Blanchard grinding is known for its ability to quickly and efficiently remove large amounts of material, making it suitable for roughing operations. 2. Precision Grinding: This method is often used for finishing operations, where a high degree of accuracy and surface finish is required. Precision grinding involves using a surface grinder with a fine-grit grinding wheel to remove a small amount of material from the surface of the steel. This process is typically slower and more precise than Blanchard grinding, resulting in a smoother and more polished surface. 3. Centerless Grinding: This method is commonly used for cylindrical steel parts that require a high degree of precision. Centerless grinding involves feeding the steel between a grinding wheel and a regulating wheel, with the grinding wheel removing material from the surface as it rotates. The regulating wheel controls the speed and feed rate of the steel, ensuring consistent and accurate grinding. 4. Creep Feed Grinding: This method is used for heavy stock removal on large steel parts. Creep feed grinding involves using a slow feed rate and deep cuts to remove material from the surface. This method is typically used for specialized applications where traditional surface grinding methods are not suitable due to the size or complexity of the steel part. Overall, the choice of surface grinding method for special steel will depend on factors such as the desired surface finish, accuracy requirements, and the size and complexity of the steel part. It is important to consult with a skilled grinding professional to determine the most appropriate method for a specific application.

- Q: Is special steel suitable for manufacturing firearms?

- Yes, special steel is highly suitable for manufacturing firearms. Special steel alloys are specifically designed to possess exceptional properties such as high strength, hardness, and resistance to wear and corrosion. These characteristics are crucial for firearms as they need to withstand high pressures, recoil forces, and intense heat generated during firing. Special steel alloys, such as stainless steel or chrome-molybdenum steel, offer excellent tensile strength, allowing firearms to handle the immense pressure generated by the ignition of gunpowder. Moreover, the hardness of special steel ensures that the critical components, such as barrels and receivers, are durable and can withstand repeated use without deforming or cracking. Firearms also require resistance to wear and corrosion, as they are often exposed to harsh environments and various weather conditions. Special steel alloys are engineered to have superior resistance to both wear and corrosion, ensuring that the firearms remain functional and reliable even after prolonged use or exposure to moisture. Furthermore, special steel alloys can be easily machined and formed into complex shapes, allowing manufacturers to create intricate firearm components with precision. This versatility in manufacturing processes enables the production of firearms that meet stringent quality standards and precise specifications. In conclusion, special steel is unquestionably suitable for manufacturing firearms due to its exceptional strength, hardness, resistance to wear and corrosion, and ease of machining. These properties ensure the reliability, durability, and performance of firearms, making special steel an ideal material choice for this purpose.

- Q: What are the requirements for special steel used in defense equipment manufacturing?

- The requirements for special steel used in defense equipment manufacturing typically include high strength and durability, resistance to corrosion and wear, good toughness and impact resistance, as well as the ability to withstand extreme temperatures and harsh environments. Additionally, the steel must meet stringent quality control standards and industry specifications to ensure its reliability and performance in critical defense applications.

Send your message to us

55Cr3 Alloy Flat Spring Steel Bars for Leaf Springs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords