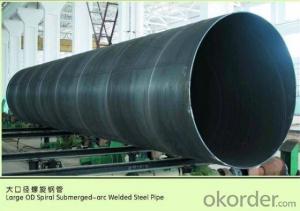

SPIRAL WELDED STEEL PIPE 16/18/20/22'' CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: Are steel pipes suitable for underground oil pipelines?

- Yes, steel pipes are suitable for underground oil pipelines. Steel pipes are commonly used in underground oil pipelines due to their durability, strength, and resistance to corrosion, making them a reliable choice for transporting oil over long distances. Additionally, steel pipes can withstand high pressure and extreme temperatures, ensuring the safe and efficient transport of oil underground.

- Q: Can steel pipes be used for brewery installations?

- Yes, steel pipes can be used for brewery installations. Steel pipes are commonly used in breweries for various applications such as transferring liquids, connecting equipment, and supporting structures. They are durable, resistant to corrosion, and can withstand high temperatures and pressures, making them suitable for brewery installations.

- Q: What is the maximum allowable deflection for steel pipes?

- Industry standards and design codes typically determine the maximum allowable deflection for steel pipes. These regulations specify the acceptable limits of deflection to guarantee the pipes' structural integrity and functionality. The maximum allowable deflection can vary, depending on factors like pipe diameter, wall thickness, material properties, and the application type. To determine the specific maximum allowable deflection for a particular steel pipe application, it is crucial to reference relevant standards and codes such as the ASME B31.3 code for process piping or AWWA standards for water transmission and distribution pipes. Adhering to these guidelines ensures the safe and efficient operation of steel pipes in various industries and applications.

- Q: SC15 what does galvanized steel pipe look like?

- DN15 galvanized pipe, nominal diameter of 15mm

- Q: What are the different methods of coating steel pipes for insulation?

- There are several methods of coating steel pipes for insulation, each with its own advantages and disadvantages. 1. Thermal Insulation Coating: This method involves applying a layer of thermal insulation material, such as mineral wool or foam, onto the steel pipe. The insulation material helps to reduce heat transfer and minimize energy loss. Thermal insulation coatings are relatively easy to apply and can provide excellent insulation properties. However, they may be prone to degradation over time and may require regular maintenance and replacement. 2. Corrosion Protection Coating: Steel pipes are often coated with corrosion protection materials, such as epoxy or polyethylene, to prevent rust and corrosion. These coatings act as a barrier between the steel surface and the surrounding environment, protecting the pipe from moisture, chemicals, and other corrosive elements. Corrosion protection coatings are typically durable and long-lasting, providing effective protection for the steel pipe. However, they may not provide significant thermal insulation properties. 3. Fusion-Bonded Epoxy (FBE) Coating: FBE coating is a popular method for both insulation and corrosion protection. It involves applying a layer of epoxy powder to the steel pipe and then heating it to create a strong, durable bond. FBE coatings provide excellent adhesion and resistance to corrosion, as well as some thermal insulation properties. They are commonly used in oil and gas pipelines and can withstand high temperatures and harsh environments. 4. Polyurethane Foam Coating: Polyurethane foam is often used as an insulation coating for steel pipes. It is applied by spraying or injecting the foam onto the pipe surface, which then expands and hardens to create a protective layer. Polyurethane foam coatings provide excellent thermal insulation properties and can be applied to pipes of various sizes and shapes. However, they may require special equipment and expertise for application and may be susceptible to physical damage or moisture absorption if not properly sealed. 5. Ceramic Coating: Ceramic coatings are another option for insulating steel pipes. These coatings are typically applied using a thermal spray process, which creates a layer of ceramic material on the pipe surface. Ceramic coatings can provide high-temperature insulation, corrosion resistance, and thermal shock protection. They are commonly used in industries such as power generation and aerospace, where extreme temperature conditions are present. However, ceramic coatings can be expensive and may require specialized equipment and expertise for application.

- Q: How long is the seamless tube?

- Seamless steel tube specification: 8-1240 * 1-200mm

- Q: How are steel pipes used in the construction of bridges?

- Steel pipes are commonly used in the construction of bridges for various purposes such as supporting the bridge structure, providing stability, and facilitating the passage of fluids like water or gases. Steel pipes are used as piers or piles to support the weight of the bridge, acting as strong and durable foundations. They are also used for constructing the bridge's framework, such as beams and trusses, which provide the necessary strength and load-bearing capacity. Additionally, steel pipes may be used as conduits for utilities like water, gas, or electrical cables, allowing for efficient transportation across the bridge.

- Q: Can steel pipes be used for culvert applications?

- Yes, steel pipes can be used for culvert applications. Steel pipes are commonly used for culverts due to their strength, durability, and resistance to corrosion. They are capable of handling heavy loads and can withstand harsh environmental conditions, making them suitable for various culvert applications such as road and railway crossings, drainage systems, and stormwater management.

- Q: Can steel pipes be used for underground fire protection systems?

- Yes, steel pipes can be used for underground fire protection systems. Steel pipes are commonly used in these systems due to their durability, strength, and resistance to fire. They can effectively withstand high temperatures and provide reliable and long-lasting protection against fire hazards in underground environments.

- Q: What is the lifespan of steel pipes?

- The lifespan of steel pipes can vary depending on various factors such as the quality of the steel used, the environment in which they are installed, and the maintenance and care given to them. However, generally speaking, steel pipes can have a lifespan ranging from 20 to 100 years or even longer if properly maintained and protected against corrosion.

Send your message to us

SPIRAL WELDED STEEL PIPE 16/18/20/22'' CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords