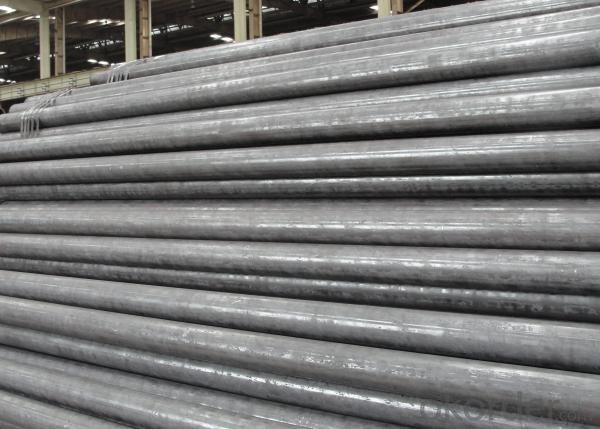

Seamless Steel Tubes And Pipes For Automotive Axle Housing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Seamless carbon steel pipes and steel tubes for automotive axle housing,pipe steel pipe

Standard: GB/T6479-2000

WT: 1mm-40mm

OD: 25mm-80mm

Length: 3000mm-12000mm

Heat treatment: Quenched and tempered , Normalized ,Tempered

Size: Cut to order and cut to size, any size is available

Surface: As your requirements

Stock: In large quantity stock

Trade terms: FOB,CFR,CIF

Payment terms: L/C,or TT 30% deposit and the balance paid against the copy B/L

Pakaging of Seamless carbon steel pipes and steel tubes for automotive axle housing,pipe steel pipe:

Wrapped in bundles with steel strips or according to customers' requirements

- Q: What is the average lifespan of a steel pipe?

- The average lifespan of a steel pipe can vary depending on various factors such as its quality, usage conditions, maintenance, and exposure to external factors. However, on average, a properly installed and maintained steel pipe can last anywhere from 20 to 100 years or more.

- Q: Can steel pipes be used for underground gas distribution?

- Indeed, underground gas distribution can make use of steel pipes. Within the gas industry, steel pipes are widely employed due to their exceptional strength, durability, and resistance to corrosion. These pipes possess the capacity to endure the pressure and stress inherent in gas distribution systems. Moreover, steel pipes have demonstrated their reliability and safety as a means of transporting natural gas below ground. Nevertheless, it is crucial to ensure that these steel pipes are adequately coated and shielded against corrosion in order to preserve their integrity and prolong their lifespan. Consistent inspections and maintenance procedures are also imperative to detect and rectify any potential problems that may arise.

- Q: How do you calculate the pipe friction loss for steel pipes?

- To calculate the pipe friction loss for steel pipes, you need to use the Darcy-Weisbach equation. This equation is commonly used in fluid dynamics to determine the pressure drop or friction loss due to the flow of fluid through a pipe. The equation is as follows: ΔP = (f * L * ρ * V²) / (2 * D) Where: ΔP = Pressure drop or friction loss f = Darcy friction factor L = Length of the pipe ρ = Density of the fluid V = Velocity of the fluid D = Diameter of the pipe The Darcy friction factor (f) is a dimensionless value that depends on the Reynolds number (Re) and the relative roughness (ε/D) of the pipe, where ε is the absolute roughness of the pipe. To determine the friction factor, you can use various correlations or Moody's diagram. Once you have the friction factor, you can plug in the values for length, density, velocity, and diameter into the equation to calculate the pressure drop or friction loss. It is important to note that the units of all the variables should be consistent (e.g., length in meters, density in kg/m³, velocity in m/s, diameter in meters) to obtain accurate results. By using this equation and obtaining the necessary parameters, you can calculate the pipe friction loss for steel pipes, which is crucial in designing and analyzing fluid flow systems.

- Q: What are the different types of thread connections used in steel pipes?

- The different types of thread connections used in steel pipes include tapered threads such as NPT (National Pipe Thread), BSPT (British Standard Pipe Taper), and API (American Petroleum Institute) threads. There are also parallel threads like BSP (British Standard Pipe) and G (ISO 228-1). These thread connections are used to join and seal steel pipes in various industries and applications.

- Q: Can steel pipes be used for conveying solids?

- Yes, steel pipes can be used for conveying solids. Steel pipes are commonly used in industries such as mining, construction, and agriculture to transport various solid materials, including ores, gravel, sand, and grains. The durability and strength of steel make it a suitable material for handling solid substances efficiently and ensuring their safe transportation.

- Q: What are steel pipes used for?

- Steel pipes are commonly used for transporting fluids and gases, as well as for structural applications such as construction, oil and gas exploration, and plumbing systems.

- Q: What is the role of steel pipes in the transportation of liquefied natural gas (LNG)?

- Steel pipes play a vital role in the transportation of liquefied natural gas (LNG) due to their unique properties and characteristics. LNG is a form of natural gas that has been cooled to a liquid state for ease of transportation and storage. The transportation of LNG requires specific infrastructure, and steel pipes are an essential component of this infrastructure. Firstly, steel pipes are used in the construction of LNG terminals and liquefaction plants. These facilities are responsible for converting natural gas into its liquid form and storing it before transportation. The extreme cold temperatures required to maintain LNG in its liquid state necessitate the use of materials that can withstand these conditions, and steel pipes are well-suited for this purpose. Steel pipes have excellent strength and durability, making them capable of handling the low temperatures and high pressures involved in the liquefaction and storage processes. Secondly, steel pipes are used in the transportation of LNG from the liquefaction plants to the storage tanks or shipping vessels. LNG is typically transported over long distances, either through pipelines or via specialized LNG carriers. Steel pipes are used in the construction of underground or above-ground pipelines, providing a reliable and safe means of transporting the LNG. The pipes must be able to maintain the low temperatures of the LNG while withstanding the pressures and stresses associated with the transportation process. Steel pipes offer the necessary strength, corrosion resistance, and thermal properties to ensure the safe and efficient transportation of LNG. Lastly, steel pipes are also used in the construction of storage tanks for LNG. These tanks are designed to maintain the LNG in its liquid state until it is ready for use or further transportation. The tanks are often constructed using a combination of steel plates and steel pipes. Steel pipes are used to connect the various components of the tank, such as the inner and outer shells, reinforcing the structural integrity of the tank and ensuring its ability to withstand the extreme conditions to which it is subjected. In summary, steel pipes play a crucial role in the transportation of liquefied natural gas (LNG) due to their strength, durability, and ability to withstand low temperatures and high pressures. From the construction of LNG terminals and liquefaction plants to the transportation through pipelines or on specialized vessels, steel pipes are a vital component of the infrastructure required for the safe and efficient transportation and storage of LNG.

- Q: How do steel pipes perform in marine environments?

- Steel pipes perform well in marine environments due to their high strength and corrosion resistance. The protective oxide layer formed on the surface of the steel helps prevent rust and deterioration caused by salty sea air and water. Additionally, steel pipes can withstand the high pressure and temperature fluctuations commonly found in marine applications, making them a reliable choice for transporting fluids and gases in offshore structures, ships, and other marine installations.

- Q: Can steel pipes be used for high-temperature applications?

- Yes, steel pipes can be used for high-temperature applications. Steel is known for its excellent strength and durability, making it suitable for handling high temperatures. However, the specific grade of steel used and the operating conditions must be considered to ensure it can withstand the desired temperature range without compromising its structural integrity.

- Q: Are steel pipes suitable for food processing facilities?

- Yes, steel pipes are suitable for food processing facilities. Steel pipes are widely used in the food processing industry due to their numerous benefits. Firstly, steel pipes are highly durable and can withstand high temperatures, pressures, and corrosive substances often used in food processing. This ensures the pipes will not degrade or contaminate the food products. Additionally, steel pipes are easy to clean and maintain, making them ideal for maintaining high levels of hygiene required in food processing facilities. Steel pipes also have excellent resistance to bacteria growth, further ensuring the safety and quality of the food being processed. Furthermore, steel pipes are cost-effective and have a long lifespan, making them a reliable and economical choice for food processing facilities. Overall, steel pipes are a suitable and preferred option for food processing facilities due to their durability, cleanliness, and resistance to contamination.

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 1991 |

| Annual Output Value | 300,000Tons |

| Main Markets | Europe; Southeast Asia; etc. |

| Company Certifications | API 5L;API 5CT;API Q1;ISO/TS29001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wuxi; Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3900-4000 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 450,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Seamless Steel Tubes And Pipes For Automotive Axle Housing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords