SPIRAL WELDED STEEL PIPE 24/26/28'’CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

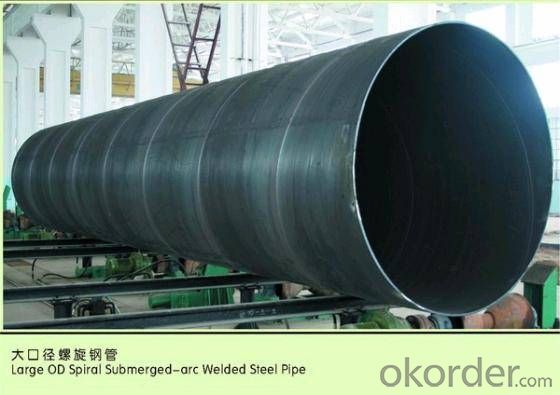

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: What are the common uses of stainless steel pipes?

- Stainless steel pipes are commonly used in various industries and applications such as plumbing, construction, oil and gas, food processing, pharmaceuticals, and automotive. They are valued for their durability, corrosion resistance, and ability to withstand high temperatures. Stainless steel pipes are utilized for transporting fluids, gases, and chemicals, as well as for structural purposes in buildings and infrastructure.

- Q: Can steel pipes be used for underground cable conduits?

- Yes, steel pipes can be used for underground cable conduits.

- Q: What is the difference between steel pipes and PVC pipes?

- Steel pipes and PVC pipes differ in material composition and their respective properties. Steel pipes are made from a combination of iron and carbon, providing them with high strength and durability. They are suitable for carrying pressurized fluids and can withstand extreme temperatures. On the other hand, PVC pipes are made from a synthetic plastic material called polyvinyl chloride. They are lightweight, easy to install, and resistant to corrosion and chemicals. PVC pipes are commonly used for drainage systems, irrigation, and household plumbing.

- Q: How to calculate the maximum bending stress of steel pipe? Is there a list of the maximum flexural normal stresses for steel pipes of different materials and diameters?

- Wnx - net sectional modulus of steel tubes, also called net sectional resistance moment. If the section is not weakened, it can be found in the steel sheet of the steel structure design manual. If the section is weakened, it can be calculated by the formula according to the sectional dimension according to the formula of the material mechanics.

- Q: What are the different shapes available for steel pipes?

- There are several different shapes available for steel pipes, including round, square, rectangular, and oval shapes.

- Q: How do steel pipes handle soil movement?

- Steel pipes are highly resistant to soil movement due to their strength and durability. The rigid nature of steel pipes allows them to withstand ground shifting and settling without deforming or breaking. Additionally, steel pipes are often installed with proper anchoring and support systems to further enhance their ability to handle soil movement.

- Q: What are the different types of steel pipe fittings for chemical processing plants?

- There are various types of steel pipe fittings used in chemical processing plants, including but not limited to, elbows, tees, reducers, flanges, and couplings. These fittings are designed to connect and control the flow of fluids within the piping system, ensuring safe and efficient operation in industrial settings.

- Q: What is the cost of steel pipes compared to other piping materials?

- The cost of steel pipes can vary based on factors like size, grade, and specifications, as well as market conditions and location. Generally, steel pipes are more expensive than materials like PVC or HDPE. However, when compared to materials like copper or stainless steel, steel pipes can often be more cost-effective. Steel pipes are known for their durability, strength, and resistance to high pressures and temperatures, making them suitable for various applications such as oil and gas pipelines, plumbing systems, and structural supports. Their longevity and reliability can offset the initial higher cost, as they require less maintenance and have a longer lifespan than other materials. Moreover, steel pipes are readily available in different sizes and grades, making them versatile and adaptable to different project requirements. This availability and versatility contribute to their cost-effectiveness, as they can be easily sourced and customized to specific needs. It is important to consider that prices for steel pipes can fluctuate due to market conditions and factors like raw material costs, transportation expenses, and labor charges. Therefore, it is advisable to consult with suppliers or industry experts for accurate pricing information based on specific project specifications and market conditions.

- Q: How are steel pipes used in the petrochemical industry?

- Steel pipes are commonly used in the petrochemical industry for various purposes such as transporting and distributing fluids and gases, as well as providing structural support for equipment. They are particularly preferred due to their high strength, durability, and resistance to corrosion, making them suitable for handling harsh and corrosive substances.

- Q: How are steel pipes used in the chemical processing industry?

- Steel pipes are commonly used in the chemical processing industry for various purposes such as transporting chemicals, gases, and liquids, as well as for structural support and containment. They are highly durable, corrosion-resistant, and can withstand high temperatures and pressures, making them ideal for handling and conveying hazardous substances safely.

Send your message to us

SPIRAL WELDED STEEL PIPE 24/26/28'’CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords