SPIRAL WELDED STEEL PIPE 16/18/20/22/24 CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

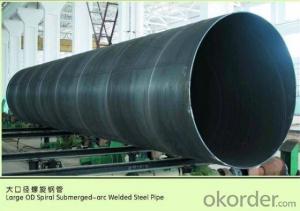

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: How are steel pipes used in the construction of desalination plants?

- Steel pipes are commonly used in the construction of desalination plants for various purposes. They are primarily utilized for the transportation of seawater and brine, as well as for the distribution of fresh water throughout the plant. Steel pipes are preferred due to their durability, corrosion resistance, and ability to withstand high pressure and extreme temperatures. Additionally, they can be easily welded together, allowing for efficient installation and maintenance.

- Q: How do you prevent steel pipes from rusting?

- Various measures can be taken to prevent the rusting of steel pipes. One effective method is the application of a protective coating on the surface of the pipes. Different types of coatings, such as paint, epoxy, or zinc, can be used for this purpose. These coatings act as a barrier between the steel and the corrosive environment, thereby preventing direct contact between moisture, oxygen, and the metal, which can lead to rust formation. Another approach involves the use of corrosion inhibitors. These substances are added to the water or fluid flowing through the pipes, creating a protective film on the surface of the steel. This film acts as a shield, inhibiting the corrosion process and preventing the formation of rust. Regular maintenance plays a crucial role in preventing rust on steel pipes. It is essential to inspect the pipes regularly for any signs of damage or corrosion and promptly repair or replace any compromised areas. Additionally, keeping the pipes clean and dry by removing accumulated dirt or moisture helps prevent the formation of rust. In some cases, using stainless steel pipes instead of regular steel can be beneficial. Stainless steel contains chromium, which forms a passive oxide layer on the metal's surface. This layer acts as a natural barrier against corrosion, making stainless steel pipes highly resistant to rust. Finally, controlling the installation environment of the pipes can also help prevent rust. This can be achieved by maintaining proper ventilation, controlling humidity levels, and avoiding exposure to harsh chemicals or corrosive substances. By implementing these preventive measures, the lifespan and integrity of steel pipes can be significantly extended, while minimizing the risk of rust formation.

- Q: What is the difference between seamless steel pipes and seamless stainless steel pipes?

- The main difference between seamless steel pipes and seamless stainless steel pipes lies in their composition. Seamless steel pipes are made from carbon steel, while seamless stainless steel pipes are made from an alloy of stainless steel, which contains chromium and nickel. This alloy gives stainless steel pipes their unique properties such as corrosion resistance, durability, and a shiny appearance. Additionally, stainless steel pipes are often used in applications where hygiene and sanitation are crucial, such as in the food and pharmaceutical industries.

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Yes, steel pipes can be used for conveying sewage and wastewater. Steel pipes are commonly used in sewage and wastewater systems due to their durability and strength. They are resistant to corrosion and can withstand high pressure and flow rates. Additionally, steel pipes are able to handle the harsh chemicals and contaminants present in sewage and wastewater without deteriorating or affecting the quality of the conveyed fluids. However, it is important to ensure that the steel pipes are properly coated or lined to prevent any potential corrosion or contamination issues. Regular maintenance and inspections are also necessary to identify and address any potential issues that could arise in the system.

- Q: Can steel pipes be used for electrical conduits?

- No, steel pipes are not typically used for electrical conduits as they are conductive and can pose a safety risk. Electrical conduits are usually made of non-conductive materials such as PVC or metal with insulating coatings.

- Q: Why seamless steel pipe called seamless steel pipe?

- Steel pipe is divided into seamless steel pipe and welded steel pipe two kinds: seamless steel pipe is ingot or tube billet, through the perforation made capillary, and then by hot rolling, cold rolling or cold drawn made, so seamless steel pipe is divided into hot-rolled and cold drawn two categories. Welded steel pipe is through the steel plate or steel strip after bending forming, and then welded to make, according to the form of weld is divided into longitudinal welded pipe and spiral welded pipe two kinds. It is obvious that seamless welded pipe has no weld and that welded steel pipe has weld line.

- Q: What is the typical diameter range of steel pipes?

- The diameter of steel pipes can vary depending on factors such as the intended use, industry standards, and project requirements. Generally, steel pipes come in a wide range of diameters to cater to different needs. Typical sizes can range from small diameters of approximately 0.5 inches (12.7 mm) to larger diameters of several feet or more. This wide range allows for various applications, including plumbing, oil and gas transportation, structural support, and industrial processes. Ultimately, the diameter of a steel pipe will be determined by the specific requirements of the project or application.

- Q: How are steel pipes protected from damage during transportation?

- Steel pipes are protected from damage during transportation through various methods. One common method is the use of protective coatings. Steel pipes are often coated with materials such as epoxy, zinc, or polyethylene to create a barrier between the pipe and external elements. These coatings help to prevent corrosion and damage during transit. Furthermore, steel pipes are often bundled together and secured using straps or bands. This bundling helps to keep the pipes in place and prevents them from shifting or rolling during transportation. Additionally, padding or cushioning materials such as foam or rubber may be used to provide extra protection and minimize the risk of damage from impact or vibration. In some cases, steel pipes may be placed in crates or containers to provide additional protection. Crates are designed to fit the pipes snugly and provide a secure enclosure that prevents external forces from causing damage. Containers, on the other hand, offer a protective environment for the pipes, shielding them from the elements and potential impacts. To ensure the safe transportation of steel pipes, it is also important to consider proper handling and loading techniques. Pipes should be carefully lifted and loaded onto transport vehicles using appropriate equipment, such as cranes or forklifts, to minimize the risk of damage. Proper securing of the pipes within the transport vehicle is crucial to prevent movement and potential damage during transit. Overall, a combination of protective coatings, bundling, padding, and secure packaging or loading techniques are employed to safeguard steel pipes from damage during transportation. These measures help to ensure that the pipes arrive at their destination in optimal condition, ready for use in various applications.

- Q: How do you prevent steel pipes from freezing?

- One way to prevent steel pipes from freezing is to insulate them with pipe insulation or heat tape. Additionally, keeping the area around the pipes well-heated and ensuring proper ventilation can help prevent freezing.

- Q: How are steel pipes used in construction?

- Steel pipes are commonly used in construction for various purposes such as structural supports, plumbing systems, and underground utility installations. They provide strength, durability, and resistance to corrosion, making them ideal for carrying fluids, gases, and other materials. Additionally, steel pipes can be easily welded, allowing for efficient and secure connections in building frameworks and infrastructure.

Send your message to us

SPIRAL WELDED STEEL PIPE 16/18/20/22/24 CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords