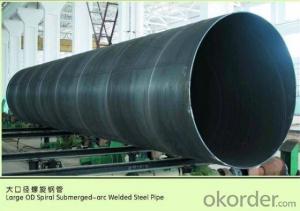

SPIRAL WELDED STEEL PIPE 12'' 14‘’ MIDDLE DIMETER CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: What does seamless steel tube mean? What are the main uses? What are the classifications?

- 1.: Construction of the underground pipeline, levy more pumping, boiler hot water transportation etc..2., mechanical processing, bearing sets, processing machinery parts.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes such as the foundation, tower, and substructure. These pipes provide structural support and stability to the turbine, ensuring its ability to withstand harsh offshore conditions and strong winds. Additionally, steel pipes are used to transport electrical cables, allowing the turbines to generate and transmit electricity efficiently.

- Q: How do you join two steel pipes together without welding?

- There are various ways to join two steel pipes together without welding. Mechanical fittings or connectors are commonly used for this purpose. These fittings are designed to securely connect pipes without the need for welding. Here are a few options you can explore: 1. Threaded Fittings: You can use threaded fittings, which have male and female threads that allow you to screw them together. To join the pipes, you will need to cut the ends of the pipes to create male and female threads. Apply thread sealant to ensure a tight and leak-free connection. 2. Compression Fittings: Another option is compression fittings, which consist of a nut, a compression ring, and a compression seat. These fittings create a tight seal by compressing the ring against the seat. Simply slide the compression ring and nut onto the pipe ends, and use a wrench to tighten the nut until a secure connection is formed. 3. Flange Connections: Flange connections involve using flanges, which are flat plates with bolt holes, to join the pipes. The flanges are bolted together using gaskets to create a tight seal. This method is commonly used for larger diameter pipes or in situations where frequent disassembly may be necessary. 4. Grooved Couplings: Grooved couplings are another option, particularly in plumbing and fire protection systems. They utilize a mechanical coupling housing with two grooved ends that fit over the pipe ends. The coupling is then secured using bolts or screws, which tighten the housing around the pipe ends, creating a secure connection. Before deciding on a method, it is crucial to consider the specific requirements of your application, such as the pipe diameter, pressure, and temperature. Additionally, ensure that the chosen method complies with relevant industry standards and regulations to ensure a safe and reliable connection.

- Q: What does "SC50" steel pipe mean in civil engineering?

- Welded steel pipe refers to the use of steel or steel plate bending deformation into a round, square and other shapes after welding into the surface of the joint of the steel pipe. The blank used in welded steel pipe is steel or strip steel.

- Q: What is the role of steel pipes in the aerospace industry?

- Steel pipes in the aerospace industry serve various critical roles, primarily in the construction of aircraft structures and engines. They are commonly used for fuel and hydraulic systems, as well as for carrying pressurized air and gases. Steel pipes provide strength, durability, and resistance to high temperatures and pressure, ensuring the safety and reliability of aerospace components. Additionally, they contribute to fuel efficiency by reducing weight and minimizing fuel leakage.

- Q: What are the different types of steel pipe flanges?

- There are several different types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, lap joint flanges, and orifice flanges. Each type has its own unique design and purpose, catering to specific applications and requirements in various industries.

- Q: What is the cost of steel pipes compared to other materials?

- The cost of steel pipes compared to other materials can vary depending on factors such as size, grade, and market conditions. However, in general, steel pipes tend to be more cost-effective and economical compared to other materials like copper or PVC. Steel is a durable and versatile material that offers excellent strength and longevity, making it a preferred choice in various industries such as construction, oil and gas, and plumbing.

- Q: How are steel pipes used in the wastewater treatment industry?

- Steel pipes are commonly used in the wastewater treatment industry for various purposes, including the transportation of wastewater from one area to another, the distribution of treated water to different locations, and the construction of infrastructure such as pumping stations and treatment plants. Due to their durability, resistance to corrosion, and ability to withstand high pressure, steel pipes are essential components in the efficient and reliable operation of wastewater treatment systems.

- Q: Can steel pipes be used for underground sewage treatment plants?

- Yes, steel pipes can indeed be used for underground sewage treatment plants. Steel pipes are commonly used in underground applications due to their durability, strength, and resistance to corrosion. They are capable of withstanding the harsh underground environment and can efficiently transport sewage from one area to another within the treatment plant. Moreover, steel pipes can be customized to meet the specific requirements of the sewage treatment plant, such as different diameters and wall thicknesses, ensuring proper flow and drainage. Additionally, steel pipes can be coated or lined with protective materials to enhance corrosion resistance, further extending their lifespan. Overall, steel pipes are a reliable and suitable choice for underground sewage treatment plants.

- Q: How are steel pipes used in offshore wind farms?

- Steel pipes are used in offshore wind farms for a variety of purposes. They are commonly used as foundation structures to support wind turbine towers, providing stability and strength in the harsh marine environment. Steel pipes are also used for subsea cables and pipelines, allowing for the transportation of electricity and other resources. Additionally, they play a crucial role in the installation of offshore wind turbines, serving as installation aids and providing access for maintenance and repair activities. Overall, steel pipes are essential components in the construction, operation, and maintenance of offshore wind farms.

Send your message to us

SPIRAL WELDED STEEL PIPE 12'' 14‘’ MIDDLE DIMETER CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords