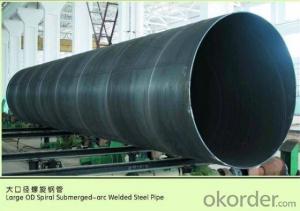

SPIRAL WELDED STEEL PIPE 12'' 16‘’ CARBON STEEL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: What are the different types of steel pipe connections for oil and gas pipelines?

- There are several types of steel pipe connections used for oil and gas pipelines, including threaded connections, welded connections, flanged connections, and grooved connections. Threaded connections involve screwing two pipe ends together using threads, providing a secure and leak-proof joint. Welded connections involve fusing pipe ends together using heat, creating a strong and durable joint. Flanged connections use a flange on each pipe end that is bolted together, providing a sturdy and easily removable joint. Grooved connections involve utilizing a groove on each pipe end, which is then locked together using a coupling, ensuring a reliable and flexible joint.

- Q: How are steel pipes protected against chemical corrosion?

- Steel pipes are protected against chemical corrosion through various methods such as coating them with corrosion-resistant materials like epoxy or polyethylene. Additionally, cathodic protection techniques like applying sacrificial anodes or using impressed current systems can also be employed to prevent chemical corrosion on steel pipes.

- Q: What is an electric welded pipe (EFW)? Seek help!

- According to the operation requirements of the electric welding machine, connect the lead wire and set up the proper welding parameter of the electric welding machine, which can be operated by manual or automatic two input methods.After checking, start the electric welding machine and enter the welding process. When the welding time is reached, the machine will automatically enter the cooling state.When the pipe completely removed after cooling, electric fusion welding machine.Cutting the pipe with the cutting tool of plastic pipe or fine toothed saw with cutting guide device, and making its end face perpendicular to the axis of pipe. Remove the edges of the edges with a knife, scrape the weld area in the pipe or spigot end and clean the weld area.Should use the special fixture as far as possible to secure the components to be connected, and the roundness of the pipe shall not exceed 1.5% of the outer diameter of the pipe, or it should be corrected on the corresponding fixture.

- Q: What does the diameter of a steel pipe project mean?

- Generally, the diameter of steel pipe has three common diameters: outer diameter, inner diameter and nominal diameter.The first two are well understood.Nominal diameter refers to the national standard to specify the general diameter of a certain national standard pipe. It is only a model representation. It is neither outer diameter nor inner diameter.

- Q: How do steel pipes compare to other pipe materials like PVC or copper?

- Steel pipes have distinct advantages over other pipe materials like PVC or copper. Firstly, steel pipes are extremely durable and can withstand high pressure and temperature, making them suitable for various industrial applications. They also have a longer lifespan compared to PVC or copper pipes, reducing the need for frequent replacements. Moreover, steel pipes are highly resistant to corrosion and chemical reactions, ensuring a consistent flow of water or other substances. However, steel pipes are generally more expensive and require skilled labor for installation. PVC pipes, on the other hand, are lightweight, cost-effective, and easier to install, but they may not be as durable or resistant to extreme conditions. Copper pipes are known for their excellent heat conductivity and resistance to fire, but they are more expensive and require more maintenance. Ultimately, the choice between steel, PVC, or copper pipes depends on the specific requirements of the project and the factors of cost, durability, and functionality.

- Q: Are steel pipes resistant to earthquakes?

- Steel pipes are generally more resistant to earthquakes compared to other materials due to their strength and flexibility. However, their ability to withstand seismic events depends on various factors such as the design, installation, and support systems in place. Overall, steel pipes can provide a higher level of earthquake resistance, but proper engineering and construction practices are crucial to ensure their effectiveness.

- Q: How do you calculate the weight of steel pipes?

- To calculate the weight of steel pipes, you can use the formula: weight = volume × density. The volume can be calculated by multiplying the cross-sectional area of the pipe with its length, while the density of steel is typically assumed to be 7850 kilograms per cubic meter.

- Q: Are steel pipes suitable for use in nuclear power plants?

- Yes, steel pipes are suitable for use in nuclear power plants. They are commonly used in various applications within the plants, including cooling systems, steam generation, and transporting fluids. Steel pipes offer excellent strength, durability, and resistance to high temperatures and pressures, making them ideal for handling the demanding conditions present in nuclear power plants. Additionally, steel pipes can be designed to meet the specific requirements of nuclear applications, ensuring their safety and reliability.

- Q: Are steel pipes suitable for conveying fluids?

- Yes, steel pipes are suitable for conveying fluids. Steel pipes have been widely used in various industries for many years due to their durability, strength, and resistance to corrosion. These qualities make steel pipes an ideal choice for conveying fluids such as water, oil, gas, and even hazardous chemicals. The smooth interior surface of steel pipes also allows for efficient flow and prevents clogging, making them suitable for applications that require a continuous and smooth flow of fluids. Furthermore, steel pipes can withstand high pressure and temperature conditions, making them suitable for both high and low-pressure fluid transmission systems. Overall, steel pipes are a reliable and efficient option for conveying fluids in a wide range of industries, including oil and gas, water treatment, chemical processing, and many more.

- Q: How do steel pipes handle seismic activities?

- Steel pipes are highly durable and resistant to seismic activities. Their strong and flexible nature allows them to withstand the ground shaking during earthquakes without compromising their structural integrity. Steel pipes are designed to absorb and distribute the energy generated by seismic waves, minimizing the potential damage caused by earthquakes. Additionally, their high strength-to-weight ratio makes them ideal for withstanding the lateral forces and ground movements associated with seismic activities.

Send your message to us

SPIRAL WELDED STEEL PIPE 12'' 16‘’ CARBON STEEL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords