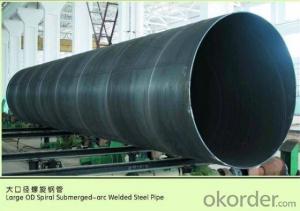

SPIRAL WELDED STEEL PIPE 14/16/18 MIDDLE DIMETER CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: What are the different methods of inspecting steel pipes for defects?

- There are several methods of inspecting steel pipes for defects, including visual inspection, magnetic particle testing, ultrasonic testing, radiographic testing, and eddy current testing.

- Q: How are steel pipes recycled at the end of their life cycle?

- Steel pipes are typically recycled at the end of their life cycle through a process called steel scrap recycling. This involves collecting the used pipes, cleaning them to remove any contaminants, and then shredding or cutting them into smaller pieces. These pieces are then melted down in a furnace to create new steel products, including pipes. The recycled steel pipes are then ready for use in various industries, reducing the need for new production and conserving valuable resources.

- Q: Why can't stainless steel be put together with carbon steel tube?

- 1, the potential difference is: potential "stainless steel tube" and the negative potential "carbon steel" coupled "stainless steel", "a cathode carbon steel tube" is anode potentials of the two difference the greater the galvanic corrosion is bigger.2. An electronic passage formed by wire connection or direct contact. The carbon in the carbon steel tube loses its electrons to the stainless steel tube and the surface is absorbed by the etchant.3. Electrolyte: the contact area of two metals is covered or submerged by electrolyte. The iron in the carbon tube loses electrons to form ions into the solution, and the electrons on the surface of the stainless steel tubes are taken away by the corrosive agents in the electrolyte (such as oxygen in the air). Electrolytes become ionic channels.

- Q: How are steel pipes used in the automotive industry?

- Steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and resistance to high temperatures, making them ideal for carrying exhaust gases, fuel, and providing support to the vehicle's frame.

- Q: What are the different types of steel pipe flanges?

- There are several types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, lap joint flanges, and blind flanges. Each type has its own unique design and application, catering to various piping systems and requirements.

- Q: Can steel pipes be used for scaffolding and support structures?

- Yes, steel pipes can be used for scaffolding and support structures. Steel pipes are commonly used in construction due to their strength, durability, and ability to withstand heavy loads. They provide a stable and secure framework for scaffolding and support structures, ensuring the safety of workers and the stability of the construction project. Steel pipes are also versatile and can be easily assembled and disassembled, making them an ideal choice for temporary structures like scaffolding. Additionally, steel pipes are resistant to corrosion, making them suitable for outdoor applications and ensuring the longevity of the scaffolding and support structures.

- Q: How are steel pipes used in railway infrastructure?

- Steel pipes are used in railway infrastructure for various purposes such as constructing bridges, tunnels, and track supports. They are also used for drainage systems, signaling and telecommunication cables, and as conduits for electrical wiring.

- Q: How are steel pipes used in underground drainage systems?

- Steel pipes are commonly used in underground drainage systems due to their durability and strength. They are used to transport wastewater, stormwater, and other liquids away from buildings and infrastructure to a designated discharge point. The steel pipes provide a reliable and long-lasting solution, ensuring the efficient flow of water and preventing any potential leaks or damage to the surrounding environment.

- Q: How are steel pipes protected against microbial corrosion?

- Various methods are employed to safeguard steel pipes against microbial corrosion. One widely used technique entails applying coatings onto the surface of the pipes. These coatings act as a shield, effectively blocking the entry of microbes and their corrosive byproducts into the steel, thereby safeguarding it from degradation. Coatings like epoxy, polyethylene, and fusion bonded epoxy are frequently utilized to bestow this protection. Another method involves the use of corrosion inhibitors. These inhibitors are added to the fluid that flows through the pipes in order to impede microbial growth and prevent corrosion. They can be either organic or inorganic compounds that function by either eradicating the microbes or inhibiting their metabolic activity. Furthermore, ensuring proper maintenance and cleaning of the pipes is vital in preventing microbial corrosion. Regular inspections and cleaning routines aid in the elimination of any biofilms or microbial deposits that may have formed on the pipe's surface. This significantly reduces the likelihood of microbial corrosion and prolongs the lifespan of the pipes. In certain cases, cathodic protection may also be employed. This method entails utilizing sacrificial anodes or impressed current systems to supply a protective electrical current to the pipe. This current helps prevent the formation of corrosive microorganisms and shields the steel from corrosion. In summary, a combination of coatings, corrosion inhibitors, regular maintenance, and cathodic protection techniques are employed to protect steel pipes from microbial corrosion. By utilizing these strategies, the longevity and integrity of the pipes are ensured, benefiting various industries such as oil and gas, water supply, and sewage systems.

- Q: What are the different types of expansion joints used with steel pipes?

- There are several types of expansion joints commonly used with steel pipes, including bellows expansion joints, slip expansion joints, and flanged expansion joints. Bellows expansion joints are flexible connectors made of a series of convolutions that allow for axial, lateral, and angular movement. Slip expansion joints consist of two pipe sections with a sliding sleeve in between, allowing for limited axial movement. Flanged expansion joints are designed with flanged ends to provide flexibility and accommodate movement in all directions. These various types of expansion joints are used to absorb thermal expansion, vibration, and misalignment in steel pipe systems.

Send your message to us

SPIRAL WELDED STEEL PIPE 14/16/18 MIDDLE DIMETER CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords