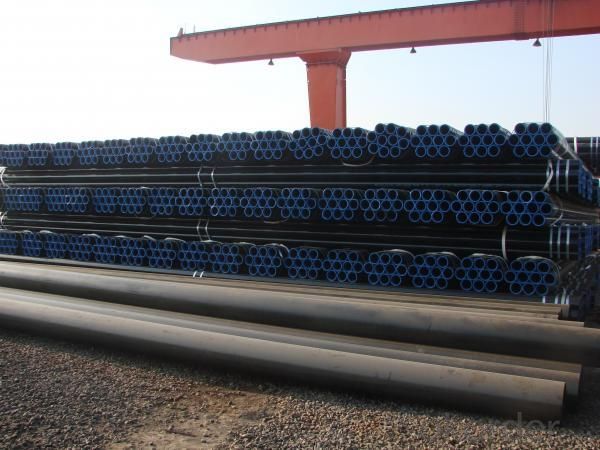

API 5L Line Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- Based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

API 5L Line Pipes

Application of API 5L Line Pipes:

It is widely applied to line pipe and casing and tubing in oil transportation and casing field, and it is used in Low,high pressure liquid and gassy transportation and it is also good Structure pipe (for furniture, window, door, building , bridge, mechanical etc).

Package of API 5L Line Pipes:

Bundles with anti-rust painting and with plastic caps

Standard of API 5L Line Pipes:

API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9711.1

Steel Grade of API 5L Line Pipes:

API SPEC 5L: B, X42, X46, X52, X56, X60, X65

API SPEC 5CT: J55, K55, N80, L80-1

ASTM A53: A, B, C

GB/T9711.1:L242、L290、L320、L360、L390、L415、L450

Sizes of pipes of API 5L Line Pipes:

*Remark: Besides below sizes, we also can arrange production based on requirement of customers

OD | WT | WEIGHT | ||||

INCH | MM | SCH | MM | INCH | KG/M | LB/INCH |

1 1/2” | 48.3 | STD-40 | 3.68 | 0.145 | 4.09 | 2.75 |

1 1/2” | 48.3 | XS-80 | 5.08 | 0.2 | 5.47 | 3.68 |

2” | 60.3 | STD-40 | 3.91 | 0.154 | 5.49 | 3.69 |

2” | 60.3 | XS-80 | 5.54 | 0.218 | 7.56 | 5.08 |

2 1/2” | 73 | STD-40 | 5.16 | 0.203 | 8.72 | 5.86 |

2 1/2” | 73 | XS-80 | 7.01 | 0.276 | 11.52 | 7.74 |

3” | 88.9 | STD-40 | 5.49 | 0.216 | 11.41 | 7.67 |

3” | 88.9 | XS-80 | 7.62 | 0.3 | 15.43 | 10.37 |

3 1/2” | 101.6 | STD-40 | 5.74 | 0.226 | 13.71 | 9.21 |

3 1/2” | 101.6 | XS-80 | 8.08 | 0.318 | 18.83 | 12.65 |

4” | 114.3 | STD-40 | 6.02 | 0.237 | 16.24 | 10.91 |

4” | 114.3 | XS-80 | 8.56 | 0.337 | 22.55 | 15.15 |

5” | 141.3 | STD-40 | 6.55 | 0.258 | 21.99 | 14.78 |

5” | 141.3 | XS-80 | 9.53 | 0.375 | 31.28 | 21.02 |

6” | 168.3 | STD-40 | 7.11 | 0.28 | 28.55 | 19.19 |

6” | 168.3 | XS-80 | 10.97 | 0.432 | 42.99 | 28.89 |

8” | 219.1 | STD-40 | 8.18 | 0.322 | 42.98 | 28.88 |

8” | 219.1 | XS-80 | 12.7 | 0.5 | 65.3 | 43.88 |

10” | 273 | STD-40 | 9.27 | 0.365 | 60.9 | 40.92 |

10” | 273 | 80 | 15.09 | 0.594 | 96.95 | 65.15 |

12” | 323.8 | STD | 9.53 | 0.375 | 74.61 | 50.13 |

12” | 323.8 | 40 | 10.31 | 0.406 | 80.51 | 54.1 |

12” | 323.8 | XS | 12.7 | 0.5 | 98.42 | 66.14 |

12” | 323.8 | 80 | 17.48 | 0.688 | 133.38 | 89.63 |

14” | 355.6 | 40 | 11.13 | 0.438 | 95.51 | 64.18 |

14” | 355.6 | XS | 12.7 | 0.5 | 108.48 | 72.9 |

14” | 355.6 | 80 | 19.05 | 0.75 | 159.71 | 107.32 |

16” | 406.4 | XS-40 | 12.7 | 0.5 | 124.55 | 83.69 |

18” | 457 | STD | 9.53 | 0.375 | 106.23 | 71.38 |

18” | 457 | 40 | 14.27 | 0.562 | 157.38 | 105.75 |

18” | 457 | 80 | 23.83 | 0.938 | 257.13 | 172.78 |

20” | 508 | 40 | 15.09 | 0.594 | 185.28 | 124.5 |

20” | 508 | 80 | 26.19 | 1.031 | 314.33 | 211.22 |

Raw Materials

- Q: What are the common uses of stainless steel pipes?

- Various industries widely use stainless steel pipes for numerous purposes. Some common applications of these pipes include: 1. Plumbing and Water Supply: Stainless steel pipes are popularly utilized in residential, commercial, and industrial plumbing systems due to their resistance against corrosion, durability, and capacity to handle high-pressure situations. They are also employed in water treatment plants and wastewater management systems. 2. Oil and Gas Industry: The oil and gas industry extensively relies on stainless steel pipes for the transportation of oil, gas, and other fluids. These pipes can endure high temperatures, pressure, and corrosive environments, making them ideal for this sector. 3. Food and Beverage Industry: The food and beverage industry frequently employs stainless steel pipes because of their hygienic properties and ability to resist corrosion. These pipes are commonly used for the transportation of liquids, gases, and food products in processing plants, breweries, wineries, dairies, and other food-related facilities. 4. Chemical and Petrochemical Industry: Stainless steel pipes play a critical role in the chemical and petrochemical industry, where they are utilized for transporting corrosive chemicals, acids, and other hazardous substances. The pipes' resistance to corrosion and high temperatures makes them suitable for these demanding applications. 5. Construction and Architecture: Stainless steel pipes are utilized in construction and architecture for various purposes such as providing structural support, creating handrails, guardrails, and decorative elements. Their strength, durability, and aesthetic appeal make them a popular choice in contemporary architectural designs. 6. Automotive and Transportation: The automotive industry relies on stainless steel pipes for exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion. These pipes are also used in the transportation of fluids and gases in ships, trains, and airplanes. 7. Pharmaceutical Industry: The pharmaceutical industry necessitates high-quality materials that adhere to stringent sanitary standards. Stainless steel pipes are commonly used in pharmaceutical manufacturing processes for transporting liquids, gases, and chemicals due to their cleanability, resistance to corrosion, and compatibility with pharmaceutical products. 8. Power Generation: Stainless steel pipes find applications in power plants, both conventional and renewable, for various purposes such as steam lines, condensers, and heat exchangers. These pipes are selected for their ability to withstand high temperatures, pressure, and corrosive environments. In conclusion, stainless steel pipes have a wide range of applications in various industries, including plumbing, oil and gas, food and beverage, chemical and petrochemical, construction, automotive, pharmaceutical, and power generation. Their resistance to corrosion, durability, and ability to handle high temperatures and pressure make them a versatile and reliable choice for numerous industrial applications.

- Q: Can steel pipes be bent or curved?

- Yes, steel pipes can be bent or curved using specialized machinery and techniques such as cold bending, induction bending, or hot bending.

- Q: How are steel pipes used in natural gas processing plants?

- Steel pipes are used in natural gas processing plants to transport and distribute the gas throughout the facility. They provide a reliable and durable infrastructure for the safe and efficient movement of gas from extraction to processing and distribution.

- Q: What are the different types of thread connections used in steel pipes?

- The different types of thread connections commonly used in steel pipes include tapered threads such as NPT (National Pipe Taper), BSPT (British Standard Pipe Taper), and API (American Petroleum Institute) threads, as well as straight threads like NPS (National Pipe Straight), BSPP (British Standard Pipe Parallel), and API threads. These connections are used to ensure a secure and leak-proof joint between pipe sections or fittings.

- Q: What are the different sizes of steel pipes available?

- Steel pipes are available in a wide range of sizes, varying from small diameter pipes used for plumbing applications to large diameter pipes used for industrial purposes. The sizes typically range from 1/8 inch to 72 inches in diameter, with various wall thickness options.

- Q: What are the different methods of joining steel pipes?

- There are several methods of joining steel pipes, including welding, threading, flanging, grooving, and using mechanical couplings.

- Q: How are steel pipes protected from corrosion?

- Steel pipes are protected from corrosion through various methods such as applying protective coatings like paint or epoxy, galvanization, and cathodic protection. These measures create a barrier between the steel surface and corrosive elements to prevent the pipes from rusting and deteriorating.

- Q: Can steel pipes be used for hydropower generation?

- Indeed, the utilization of steel pipes is possible for the generation of hydropower. Within hydropower systems, steel pipes find widespread application in various contexts like penstocks and pipelines. Penstocks, characterized by their large size, are responsible for transporting water from a reservoir to a turbine, facilitating the conversion of the water's kinetic energy into rotational energy. Consequently, these pipes necessitate robustness and longevity to endure the immense water pressure and structural weight. Furthermore, steel pipes are also employed for pipelines, facilitating the transportation of water from the turbine back to the river or reservoir. Ultimately, steel pipes are an indispensable element in the generation of hydropower, as they possess the necessary strength, durability, and resilience to withstand the challenging conditions associated with water flow.

- Q: What are the different methods of pipe welding for steel pipes?

- Steel pipes can be welded using various methods, each with its own advantages and applications. Here are some commonly used techniques: 1. Stick welding, also called Shielded Metal Arc Welding (SMAW), involves manually melting a consumable electrode coated in flux. The flux creates a protective shield around the weld pool. SMAW is versatile and can be used in different positions, making it suitable for both field and workshop applications. 2. Gas Metal Arc Welding (GMAW), also known as MIG welding, uses a continuous wire electrode fed through a welding gun. The gun supplies a shielding gas, such as argon or a mixture of argon and carbon dioxide, to protect the weld pool from contamination. GMAW is known for its high welding speed and is commonly used in industrial settings. 3. Flux-Cored Arc Welding (FCAW) is similar to GMAW, but the wire electrode is filled with flux instead of relying on an external gas. The flux creates a protective shield around the weld pool, eliminating the need for a separate gas supply. FCAW is often used in outdoor and windy conditions for better protection against contamination. 4. Gas Tungsten Arc Welding (GTAW), also called TIG welding, uses a non-consumable tungsten electrode to create the weld. A separate shielding gas, typically argon, is used to protect the weld pool. GTAW produces high-quality welds with excellent control, making it suitable for precision applications. 5. Submerged Arc Welding (SAW) is an automated process that uses a continuously fed wire electrode and a granular flux poured over the weld joint. The arc is submerged beneath the flux, providing excellent protection against contamination. SAW is commonly used in heavy fabrication and pipeline industries due to its high deposition rates and deep penetration capabilities. These are just a few of the methods available for welding steel pipes. The choice of method depends on factors such as the application, material thickness, desired weld quality, and available equipment. Selecting the appropriate method is crucial to ensure strong and reliable welds in steel pipe applications.

- Q: How do you calculate the pipe thermal expansion coefficient for steel pipes?

- To calculate the pipe thermal expansion coefficient for steel pipes, you need to consider the material's linear expansion coefficient and the change in temperature. The linear expansion coefficient for steel is typically around 12 x 10^-6 per degree Celsius. First, determine the initial length of the pipe, which is denoted as L0. Then, measure the change in temperature, denoted as ΔT. Next, multiply the initial length of the pipe by the linear expansion coefficient and the change in temperature: ΔL = L0 * α * ΔT. The resulting value, ΔL, represents the change in length of the steel pipe due to thermal expansion.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2004 |

| Annual Output Value | 250,000Tons |

| Main Markets | Europe; South America; Americas;etc. |

| Company Certifications | API 5L;API 5CT;ISO 9001:2008 GB/T 19001-2008;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-2000 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 70,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

API 5L Line Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- Based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords