Special Steel W6 High Speed Tool Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The details of our Steel

1. Produce Standard: as the GB, AISI, ASTM, SAE, EN, BS, DIN, JIS Industry Standard

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment:

Normalized / Annealed / Quenched+Tempered

4. Quality assurance:

All order we can received Third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product information

Chemical Composition(GB)%

| Standard | C | Si | Mn | P | S | Cr | W | Mo | V |

| W6Mo5Cr4V2 | 0.55-0.65 | ≤0.40 | ≤0.60 | ≤0.030 | ≤0.020 | 3.70-4.30 | 6.00-7.00 | 4.50-5.50 | 1.70-1.10 |

| M2 | 0.78-0.88 | 0.20-0.45 | 0.15-0.40 | ≤0.030 | ≤0.030 | 3.75-4.50 | 5.50-6.75 | 4.50-5.50 | 1.75-2.20 |

Heat Treatment

| Item | Temperature℃ | Hardness |

| Anneal | 840-860 | ≤255HB |

| Quenching | 1150-1180 | ≥60HRC |

| Tempering | 560-580 | ≥60HRC |

Applications:Used for various tools,large thermoplastic forming cutting tools,abrasion resistance components operating under high load such as cold extrusion dies

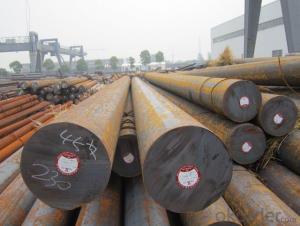

Product show

Workshop show

- Q: How does special steel resist oxidation at high temperatures?

- Due to the presence of specific alloying elements and a carefully controlled manufacturing process, special steel is able to resist oxidation at high temperatures. When exposed to oxygen in the air, alloying elements like chromium, nickel, and aluminum form a protective oxide layer on the steel's surface. This layer acts as a barrier, preventing further oxidation. Of these alloying elements, chromium is particularly effective in forming a stable and dense chromium oxide layer. This layer serves as a self-healing mechanism, meaning that if it becomes damaged or scratched, it will quickly regenerate and continue to protect the steel from oxidation. The manufacturing process of special steel involves precise control of composition and heat treatment. This ensures that the steel has a fine and uniform microstructure, minimizing the presence of impurities or defects that could speed up oxidation. Moreover, the steel often undergoes various heat treatments, such as annealing or quenching, which further enhance its resistance to oxidation. In conclusion, the combination of alloying elements, controlled composition, and specific manufacturing processes allow special steel to withstand oxidation at high temperatures. This makes it an ideal choice for applications in industries like aerospace, power generation, and petrochemical.

- Q: How does special steel contribute to the durability of products?

- Special steel contributes to the durability of products due to its unique properties and composition. It is designed to have increased strength, hardness, and resistance to wear and corrosion, making it suitable for demanding applications. Special steel enhances the structural integrity and longevity of products, ensuring they can withstand heavy loads, extreme temperatures, and harsh environments without compromising performance or safety.

- Q: How does special steel contribute to reducing product waste?

- Special steel contributes to reducing product waste in several ways. Firstly, it is known for its durability and strength, which means that products made from special steel have a longer lifespan and are less likely to break or wear out quickly. This reduces the need for frequent replacements, thereby minimizing product waste. Additionally, special steel can be fabricated into complex shapes and sizes, allowing manufacturers to optimize material usage and minimize waste during production. The ability to customize special steel to specific requirements also ensures that products are designed with the right dimensions and strength, reducing the chances of defects or inefficiencies that could lead to waste. Moreover, special steel often has superior corrosion resistance and other protective properties, making it suitable for applications where products are exposed to harsh environments or frequent use. This reduces the likelihood of premature degradation or damage, further extending the product's lifespan and reducing waste. Overall, special steel's durability, customization capabilities, and protective properties play a significant role in reducing product waste by increasing product longevity, optimizing material usage, and minimizing defects or damage.

- Q: How does special steel perform in terms of magnetic permeability?

- Special steel typically has low magnetic permeability, meaning it does not easily allow the flow of magnetic fields through it. This property makes it suitable for applications where magnetic interference needs to be minimized or controlled, such as in electrical transformers or magnetic shielding.

- Q: What are the requirements for special steel used in high-temperature applications?

- The requirements for special steel used in high-temperature applications include excellent heat resistance, high strength at elevated temperatures, good oxidation and corrosion resistance, and the ability to retain mechanical properties under extreme heat conditions. Additionally, these steels should have sufficient creep resistance, thermal stability, and resistance to thermal fatigue.

- Q: What are the properties of electrical steel?

- Electrical steel, also known as silicon steel, possesses several important properties that make it suitable for various electrical applications. It has a high magnetic permeability, which means it can efficiently conduct magnetic flux, making it ideal for use in transformers, motors, and generators. Additionally, electrical steel exhibits low core losses, reducing energy dissipation during operation. Its high electrical resistivity minimizes eddy currents, further improving efficiency. Furthermore, electrical steel has a laminated structure, reducing hysteresis losses and preventing magnetic domains from aligning, which helps in maintaining a stable magnetic field. Overall, electrical steel's properties make it a crucial material for efficient and reliable electrical devices.

- Q: How is special steel used in the medical manufacturing process?

- Special steel is used in the medical manufacturing process for various applications such as surgical instruments, implants, and medical devices. Its unique properties, including corrosion resistance, strength, and biocompatibility, make it ideal for ensuring the quality, durability, and safety of medical equipment.

- Q: What are the different casting methods used for special steel?

- There are several different casting methods used for special steel, including sand casting, investment casting, continuous casting, and centrifugal casting. Each method has its own advantages and is suited for specific applications. Sand casting is a common and cost-effective method that involves pouring molten steel into a sand mold. Investment casting, on the other hand, uses a wax pattern that is coated in a ceramic shell and then melted away to leave a cavity for the steel to be poured into. Continuous casting is a continuous process where molten steel is poured into a water-cooled mold and solidifies into a continuous strand. Finally, centrifugal casting involves spinning a mold while pouring the molten steel, creating a centrifugal force that helps distribute the metal evenly. These different methods allow for the production of special steel components with various sizes, shapes, and properties.

- Q: How does special steel contribute to the agriculture aftermarket industry?

- The agriculture aftermarket industry relies heavily on special steel, which plays a vital role in enhancing productivity and efficiency in farming operations through the provision of high-performance components and equipment. Special steel, also known as alloy steel, is specifically engineered to possess properties such as strength, durability, corrosion resistance, and heat resistance, making it well-suited for various agricultural applications. One of the major contributions of special steel to the agriculture aftermarket industry is the manufacturing of machinery parts that are durable and reliable. These parts, including plowshares, blades, and tines, face harsh conditions such as intense wear, impact, and exposure to corrosive substances. However, special steel components can endure these challenges and offer a longer service life, resulting in reduced downtime and maintenance costs for farmers. Moreover, special steel is utilized in the production of agricultural equipment such as tractors, harvesters, and sprayers. These machines require materials that are both strong and lightweight to ensure optimal performance and fuel efficiency. The use of special steel grades provides the necessary strength while keeping the equipment's weight low, enabling farmers to cover larger areas and increase their productivity. Additionally, special steel alloys are employed in the manufacturing of precision tools used in precise farming techniques, such as cutting blades and drill bits. These tools allow farmers to carry out tasks with high accuracy, such as soil sampling, seeding, and crop monitoring. The durability and sharpness of special steel tools enhance the precision and effectiveness of these operations, leading to improved crop yields and efficient use of resources. Furthermore, special steel is also utilized in the construction of infrastructure related to the agriculture aftermarket industry. Steel beams and columns, for example, are used in the fabrication of storage facilities, barns, and grain silos, providing structural strength and stability. This infrastructure enables efficient storage, handling, and transportation of agricultural products, contributing to the overall efficiency of the industry. In conclusion, special steel is an indispensable component of the agriculture aftermarket industry as it contributes to the production of durable machinery parts, lightweight equipment, precision tools, and robust infrastructure. By offering enhanced strength, durability, and corrosion resistance, special steel helps farmers improve productivity, reduce downtime and maintenance costs, and achieve better crop yields.

- Q: What are the different methods for tempering special steel?

- There are different methods available for tempering special steel, each having its own advantages and considerations. Some commonly used methods for tempering special steel are: 1. Air Tempering: Special steel is heated to a specific temperature and allowed to cool in still air. This method is suitable for low alloy steels and results in uniform hardness throughout the steel. 2. Oil Tempering: Special steel is heated to a specific temperature and then rapidly cooled by quenching it in oil. This method is commonly used for tool steels as it provides a good balance between hardness and toughness. 3. Water Tempering: Similar to oil tempering, this method involves quenching the steel in water after heating it to a specific temperature. It leads to a harder steel due to faster cooling, but it may also increase brittleness. 4. Salt Bath Tempering: The steel is immersed in a molten salt bath at a specific temperature. This method ensures controlled and uniform heat transfer, resulting in consistent hardness throughout the steel. 5. Cryogenic Tempering: Steel is cooled to extremely low temperatures, often below -100°C (-148°F), using liquid nitrogen or helium. This method further reduces residual stresses and enhances wear resistance of the steel. It is important to consider various factors such as the type of steel, desired hardness, intended application, and the required balance between hardness and toughness when choosing a specific tempering method for special steel. Following proper heat treatment guidelines and seeking advice from experts is crucial to achieve optimal results for a particular steel alloy.

Send your message to us

Special Steel W6 High Speed Tool Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords