Special Steel SKD61 Forged Hot Work Mould Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The details of our Steel

1. Produce Standard: as the GB, AISI, ASTM, SAE, EN, BS, DIN, JIS Industry Standard

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment:

Normalized / Annealed / Quenched+Tempered

4. Quality assurance:

All order we can received Third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product information

1.Equivalent Grades

H13(1.2344/SKD61), EFS H13(8407), 1.2714(SKT4/5CrNiMoV)

2.Form&Size 1)SKD61 Tool Steel round bars, flat/square bars,plates,sheets.

Round steel bar: 10-800mm(Dia)

Flat steel bar: 6-400mm*200-1600mm

2)SKD61 Tool Steel Size Available(Length can be customized)

3.Surface Condition Black,turning,peeling,milling

4.Characteristic pure steel vacuum degassing refining process ball the annealing softening treatment, good cutting performance. SKD61 picture strengthening elements vanadium, molybdenum special Add, abrasion resistance is extremely excellent.

5.Usage SKD61 a high-carbon high-chromium alloy tool steel with high hardness and wear resistance after heat treatment and hardenability, good dimensional stability, suitable for making high-precision long-life cold work die and thermosetting molding plastic mold.

6.Physical properties SKD61 Hardness: before heat treatment SKD61 about HRC15 ~ 20 (HB200 230), the hardness after heat treatment: the internal of HRC40 °~ 45 ° surface HV1000 ± 100 SKD61 density is 7.85 g per cubic centimeter.

7.heat treatment

Quenching: the first stage of warm-up: the second stage of 500 to 550 ° C Preheat: 750 ~ 800 °C quenching or high-pressure gas cooling, 100 ~ 150 °C into the back to the stove. Tempering: Preheat: 300 to 350 °C tempering heating: 550 to 680 °C air cooling to room temperature, tempering three times. Quenching temperature of 1020 to 1050 degrees, hardness 56 ~ 58HRC, heat treatment of small deformation, surface nitriding nitriding processing products have better wear resistance.

8. Cryogenic treatment

In order to obtain the highest hardness and dimensional stability, the mold immediately after the quenching cryogenic -70 to -80 ° C., maintained for 3-4 hours, and then in the tempering treatment, the cryogenic treatment of tool or mold hardness than the hardness of conventional heat treatment 1 -3HRC. Complex shape and size changes in large parts, cryogenic processing production risk of cracking.

Main product

High speed steel | |

AISI | M2,M4,M35,M42,T1 |

DIN | 1.3343,1.3243,1.3247,1.3355 |

JIS | SKH51,SKH54,SKH35,SKH59,SKH2 |

Cold work tool steel | |

AISI | D2,D5,D3,D6,A8,A2,O1 |

DIN | 1.2379,1.2601,1.2080,1.2436,1.2631,1.2363,1.2510,1.2327 |

JIS | SKD10,SKD11,SKD1,SKS3 |

Hot work tool steel | |

AISI | H13,H11,H21 |

DIN | 1.2344,1.2343,1.2367,1.2581,1.2713 |

JIS | SKD61,SKD6,SKD7,SKD5SKT4 |

Plastic mould steel | |

AISI | P20,P20+Ni,420 |

DIN | 1.2311,1.2738,1.2083,1.2316 |

JIS | PDS-3,SUS420J1,SUS420J2 |

Alloy structural seel | |

AISI | 5140,4340,4135,4140 |

DIN | 1.7035,1.6511,1.7220,1.7225 |

JIS | SCr440,SNCM439,SCM435,SCM440 |

Stainless steel | |

AISI | 440C,420,430 |

DIN | 1.4125 |

JIS | SUS440C |

Carbon steel | |

AISI | 1045,1020 |

DIN | 1.1191 |

JIS | S45C, G3101 |

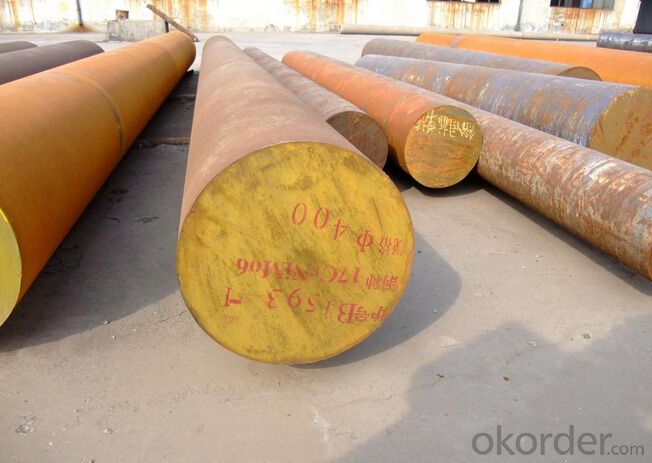

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: How does special steel contribute to the automotive suspension spring industry?

- Special steel contributes to the automotive suspension spring industry by providing enhanced strength, durability, and flexibility. This type of steel allows suspension springs to withstand the constant stress and load of vehicle weight, while also providing optimal ride comfort and handling. The high-quality properties of special steel help suspension springs to maintain their shape and performance over time, ensuring a smooth and stable ride for vehicles.

- Q: What are the specific requirements for special steel used in the defense armor industry?

- The specific requirements for special steel used in the defense armor industry are as follows: 1. High strength: Special steel used in defense armor must possess exceptional strength to withstand the impact of projectiles and explosives. It should be able to resist deformation and penetration under extreme conditions. 2. Hardness: The steel should have high hardness to provide resistance against cutting, drilling, or other forms of mechanical damage. This property ensures that the armor can withstand attacks and prevent penetration. 3. Toughness: Special steel needs to exhibit toughness, which allows it to absorb and dissipate the energy generated from impacts. This property helps to minimize the damage caused by projectiles and explosions. 4. Ballistic resistance: The steel should possess excellent ballistic resistance to effectively stop or deflect projectiles. It should be able to absorb and distribute the impact energy over a larger area, reducing the likelihood of penetration. 5. Corrosion resistance: Defense armor is exposed to various environmental conditions, including moisture and chemicals. Therefore, the special steel used in defense armor must have high corrosion resistance to ensure its longevity and effectiveness. 6. Weldability: The steel should be easily weldable to allow for the construction of complex armor structures. Weldability ensures that the armor can be conveniently assembled, repaired, or modified as per the specific requirements. 7. Heat resistance: Defense armor may need to withstand high temperatures generated from explosions or intense fire. Special steel should possess heat resistance to maintain its structural integrity and protective capabilities under such extreme conditions. 8. Lightweight: While maintaining the above properties, special steel should also be lightweight to ensure ease of mobility for soldiers and vehicles. The armor should not hinder movement or impose excessive weight burdens. Meeting these requirements is crucial to ensure the effectiveness and reliability of defense armor in providing protection to military personnel and assets.

- Q: What are the requirements for special steel used in railway applications?

- The requirements for special steel used in railway applications are quite stringent due to the demanding nature of the industry. Here are some of the key requirements: 1. High strength and durability: Special steel used in railway applications must have excellent strength and durability to withstand the heavy loads and constant vibrations experienced by trains. This helps prevent deformation, fatigue, and failure of the steel components. 2. Wear resistance: Railway tracks and other components are subject to significant wear and tear due to the constant movement of trains. Special steel used in railway applications should have good wear resistance to ensure a longer service life and reduce maintenance costs. 3. Corrosion resistance: Railway tracks and structures are often exposed to various environmental conditions, such as rain, snow, and chemicals. Special steel used in railway applications should have high corrosion resistance to prevent rusting and degradation, ensuring the longevity of the components. 4. Fatigue resistance: Trains undergo repetitive loading cycles, leading to fatigue in the steel components. Special steel should have excellent fatigue resistance to prevent cracking and failure, thereby ensuring the safety and reliability of railway systems. 5. High impact toughness: Special steel used in railway applications must possess high impact toughness to absorb energy during sudden shocks or accidents. This helps prevent catastrophic failures and ensures the safety of passengers and railway personnel. 6. Heat resistance: In some railway applications, such as high-speed trains, steel components are exposed to high temperatures due to friction or other sources. Special steel should have good heat resistance to maintain its mechanical properties and structural integrity even under elevated temperatures. 7. Dimensional stability: Special steel used in railway applications should exhibit excellent dimensional stability to maintain the required tolerances and alignment of various components. This ensures smooth operation, reduces noise, and prevents excessive wear. These are some of the primary requirements for special steel used in railway applications. Meeting these requirements is crucial to ensure the safe, reliable, and efficient operation of railway systems.

- Q: Can special steel be used in the telecommunications equipment manufacturing industry?

- Yes, special steel can be used in the telecommunications equipment manufacturing industry. Special steel, such as stainless steel or alloy steel, offers various advantages such as high strength, corrosion resistance, and heat resistance. These properties make it suitable for manufacturing various components used in telecommunications equipment, including antennas, towers, cable connectors, and enclosures. Additionally, the use of special steel can enhance the durability and performance of the equipment in challenging environments, such as extreme temperatures or exposure to harsh weather conditions.

- Q: Can special steel be used in the production of gearboxes?

- Yes, special steel can be used in the production of gearboxes. Special steel, such as alloy steel or heat-treated steel, is often preferred for gear manufacturing due to its high strength, durability, and resistance to wear and fatigue. These properties make special steel well-suited for transmitting power and withstanding the demands of heavy-duty applications, making it an ideal material choice for gearboxes.

- Q: How does special steel perform in cryogenic applications?

- Special steel is known for its excellent performance in cryogenic applications. Cryogenic temperatures refer to extremely low temperatures below -150 degrees Celsius (-238 degrees Fahrenheit). In such conditions, regular steel tends to become brittle and lose its strength, making it unsuitable for use. However, special steel, also known as cryogenic steel or low-temperature steel, is specifically designed to withstand these extreme cold temperatures. One of the key properties of special steel is its ability to maintain its mechanical properties even at cryogenic temperatures. It retains its strength, toughness, and ductility, ensuring that it can withstand the stresses and strains imposed on it in cryogenic environments. This allows special steel to be used in various applications, such as cryogenic storage tanks, pipelines, and equipment in industries like aerospace, energy, and healthcare. Special steel also exhibits excellent resistance to brittle fracture at low temperatures. This is crucial, as brittle fractures can occur when materials become too brittle and fail under stress. The unique composition and processing of special steel help prevent this, ensuring the integrity and safety of components in cryogenic systems. Moreover, special steel has a low coefficient of thermal expansion, meaning it experiences minimal dimensional changes when exposed to temperature variations. This property is highly advantageous in cryogenic applications, as it helps maintain the stability and reliability of equipment and structures. In addition, special steel offers good corrosion resistance, which is essential in cryogenic environments where the presence of moisture and certain chemicals can accelerate corrosion processes. The resistance to corrosion ensures the longevity and durability of components, reducing maintenance and replacement costs. Overall, special steel is a preferred choice for cryogenic applications due to its ability to maintain mechanical properties, resistance to brittle fracture, low thermal expansion, and corrosion resistance. These properties make it a reliable and efficient material for use in cryogenic systems, providing the necessary strength and durability even in extremely low-temperature conditions.

- Q: What are the different types of heat-resistant steel?

- There are various types of heat-resistant steel, including austenitic stainless steels, martensitic stainless steels, ferritic stainless steels, and precipitation hardening stainless steels. Additionally, nickel-based alloys such as Inconel and Hastelloy, as well as refractory metals like tungsten and molybdenum, are also considered heat-resistant steel materials.

- Q: How does special steel contribute to the infrastructure sector?

- Special steel plays a crucial role in the infrastructure sector by providing enhanced strength, durability, and resistance to various environmental factors. It is used in the construction of bridges, buildings, and other critical infrastructure projects, ensuring structural integrity and safety. Additionally, special steel is utilized in the manufacturing of machinery and equipment used in the sector, further contributing to its efficiency and reliability.

- Q: How is die steel used in metal stamping processes?

- Die steel is used in metal stamping processes as it is a strong and durable material that can withstand the high pressures and forces involved in shaping and forming metal. It is used to create dies, which are specialized tools that are used to shape and cut metal into specific designs or forms. The die steel acts as a mold or template, allowing the metal to be stamped, bent, or cut into the desired shape with precision and accuracy.

- Q: Are there any disadvantages of using special steel?

- There are several disadvantages associated with the use of special steel. To begin with, special steel tends to be more expensive compared to regular steel. This is primarily due to the additional alloying elements and heat treatments involved in its production, which contribute to the higher cost. As a result, it may not be the most cost-effective option for applications where cost is a major factor. Furthermore, special steel may have limited availability in comparison to regular steel. It is often produced in smaller quantities and may only be obtainable from specific suppliers. This can lead to longer lead times and difficulties in sourcing the required amount of special steel, particularly for large-scale projects. Additionally, the increased complexity of working with special steel can pose challenges. It may require specialized knowledge, skills, and equipment for handling and processing. If the necessary expertise or resources are not readily available, this can result in higher manufacturing costs and potential delays in production. Moreover, some special steel grades with high strength and hardness can be more prone to brittleness. This means they may be susceptible to cracking or breaking under certain conditions, especially when exposed to extreme temperatures or sudden impact loads. This limitation can be a disadvantage in applications that require high toughness or resistance to fracture. Lastly, special steel may have limited applications due to its specific properties. While it offers advantages such as corrosion resistance, high temperature resistance, or improved mechanical properties, these benefits may not be relevant or necessary for every application. Consequently, using special steel in such cases may incur unnecessary expenses without any tangible benefits. In conclusion, special steel has its drawbacks, including higher costs, limited availability, increased complexity, potential brittleness, and limited applicability. Therefore, it is crucial to carefully consider the specific requirements of a project before opting for special steel.

Send your message to us

Special Steel SKD61 Forged Hot Work Mould Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords