Single Stage Double Suction Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

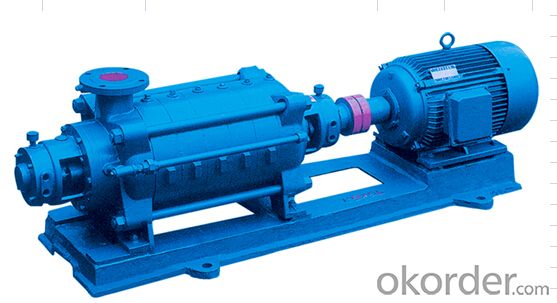

Single Stage Double Suction Centrifugal Pump

1.Structure of Single Stage Double Suction Cenrifugal Pump Description

Single Stage Double Suction Centrifugal Water Pump casing is axially split, which permits removal of the complete rotor without moving either piping or motor. Pumps generating high heads have double volutes to reduce radial forces. Replaceable wear rings protect the casing at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI.The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to NFPA 20 STANDARD .Vertical or horizontal, soft packing or mechanical seal, grease or oil lubrication bearing on request. NFPA 20 standard pump is available.

2.Main Features of the Single Stage Double Suction Cenrifugal Pump

•Diesel pump unit: diesel engine, water pump, cooling fan, cooling water tank, steel structure base (including fuel tank 80-120L), battery, connecting wires, exhaust muffler, control panel.

•Standard design is the pump group, the fuel tank, control panel, battery composite type.

•Can be designed according to customer requirement pump group, the fuel tank, control panel, battery, outdoor rainproof cabinet composite outdoor type.

•Can be designed according to customer requirement trailer (four or two wheels) moveable type.

3.Single Stage Double Suction Cenrifugal Pump images

4.Single Stage Double Suction Cenrifugal Pump Specification

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: What does the pump mortar do?

- In order to effectively reduce the flow resistance of concrete and pipe, to avoid obstruction caused by pipe sticking and to achieve normal pumping, and its role is generally only pumps.

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- The purpose of the steam separator is to separate the gas from the liquidWater ring type vacuum pump, water, compressed gas is discharged through the exhaust port, if not it is soda water separator is discharged, can not be separated, for the recovery of gas discharged industry is obviously impossible.Soda separator is available, the key is to see the working conditions

- Q: Is the diaphragm pump and the drain pump one?

- Generally composed of actuators and valves.Pneumatic diaphragm pump, which has four kinds of materials: plastic, aluminum alloy, cast iron, stainless steel. The electric diaphragm pump has four kinds of materials: plastic, aluminum alloy, cast iron and stainless steel. Diaphragm pump diaphragm according to different liquid media, respectively, NBR, chloroprene rubber, fluorine rubber, PTFE, poly 46 ethylene to meet the needs. Placed in a variety of special occasions, for pumping various media.

- Q: Does vacuum pump oil belong to dangerous goods?

- Absolutely not. We often send oil by express or by freight. There are no problems at all. Don't be afraid, don't burn, explode

- Q: Water pump does not produce water, what are the reasons?

- 4. as a water inlet valve, check whether it is normal, whether the silted up.5. the installation height of water pump exceeds the allowable suction height of pump, or the suction pipe is too long.

- Q: What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- Directly said vane pump on the line, generally do not say rotary vane pump.The centrifugal pump is divided according to the direction of the liquid flow in the impeller

- Q: Water pump spoon pipe for power plantWhich hero can tell me what is the water pump spoon tube ah? And its role

- The spoon pipe is not a feed pump, but also is an adjusting oil inlet device of a hydraulic coupler matched with a feed pump

- Q: How many concrete pump tube diameter

- High pressure is the outer diameter is Phi 140 Type 150 type low pressure pipeline; pipe diameter is Phi 159 pipeline, high pressure pipeline diameter is phi 168.

- Q: What is the nominal pressure of the hydraulic pump and hydraulic motor?

- Working pressure - the actual working pressure of the motor, that is, the pressure of the input oil. The difference between the motor inlet pressure and the outlet pressure should be calculated.Rated (nominal) pressure under normal working conditions, according to the test standards for continuous operation of the maximum pressure, that is, the rated pressure, more than the maximum pressure is called overloading.

- Q: What are the characteristics of the piston pump?

- Piston pump is an important device of hydraulic system. It depends on the plunger in the cylinder in reciprocating movement, so that the volume of the sealing chamber volume changes to achieve oil absorption and oil pressure. Plunger pump with a rated pressure, compact structure, high efficiency and flow and easy adjustment, is widely used in high pressure and large flow and flow needs to adjust the occasion, such as hydraulic machine, engineering machinery and ships.

Send your message to us

Single Stage Double Suction Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords