Sign Aluminum Sheets for Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

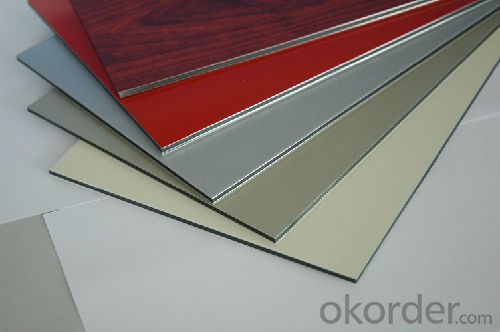

Structure of Aluminium Composite Panel Facade Decoration Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Composite Panel Facade Decoration

Extremely strong agglutination

Excellent weather resistance

Excellent fire-retardant performance

Light and easy to machining, excellent impact resistance, easy to maintain

Coating : PVDF, PE, Granite-textured, Wood-textured, Mirror

Color: at your option. ( We could mix the color according to your reqirement.)

Surface and rear aluminum foil can be coating with fresh color as your requirement.

All of Aluminum foil is made from famous aluminum manufacture

In the middle is the no-toxicity Plastic core

PVDF coating can be effected for 15 years, and the PE coating can be effected for 8 years.

Images of Aluminium Composite Panel Facade Decoration

Aluminium Composite Panel Facade Decoration Specification:

| Specification | Recommend | |

| PVDF | 4*0.4mm | Most popular in the world for out door decoration |

| 4*0.5mm | Best for out door decoration in general | |

| 4*0.3mm | Economy also meet requirement for outdoor decoration | |

| 3*0.3mm | Popular for indoor decoration in commercial building | |

| 4*0.5mm Fireproof | Superior fireproof performance on the basis of the best specification | |

| PE | 3*0.3mm | Most popular in the world for indoor decoration |

| 3*0.21mm | Economy for indoor decoration in general | |

| Standard size | 1220*2440 and 1250*2440mm | |

| Accepted width | Max:1580mm | |

| Accepted length | Max:6000mm | |

| Accepted thickness | 2mm,3mm,4mm,5mm,6mm | |

| Aluminum alloy thickness | ACP thick | AL thick |

| 2mm | 0.06mm-0.15mm | |

| 3mm | 0.06mm-0.21mm | |

| 4mm | 0.06mm-0.55mm | |

| 5mm | 0.06mm-0.55mm | |

| Weight | 5kg/m2, based on 4*0.4mm,1400pcs/20'FCL | |

| Nonstandard | Sizes are available according your requirement | |

FAQ of Aluminium Composite Panel Facade Decoration

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum sheets be custom cut to specific dimensions?

- Yes, aluminum sheets can be custom cut to specific dimensions.

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Yes, aluminum sheets are suitable for pharmaceutical packaging due to their excellent barrier properties, light weight, and resistance to corrosion. They protect pharmaceutical products from moisture, light, and oxygen, ensuring their stability and extending their shelf life. Additionally, aluminum sheets can be easily molded into different shapes, making them a versatile choice for various packaging formats in the pharmaceutical industry.

- Q: How do aluminum sheets perform in terms of fire resistance?

- Aluminum sheets have excellent fire resistance properties. Due to their high melting point, they can withstand extreme heat and do not contribute to the spread of fire. Additionally, aluminum forms a protective oxide layer when exposed to fire, which further enhances its fire resistance capabilities.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: What are the standards and certifications available for aluminum sheets?

- There are several standards and certifications available for aluminum sheets, including the American Society for Testing and Materials (ASTM) standards, the Aluminum Association standards, and the ISO 9001 certification. These standards and certifications ensure the quality, durability, and performance of aluminum sheets, and help customers make informed decisions while selecting the appropriate product for their specific applications.

- Q: What is the atomic mass of aluminum?

- Aluminum has an atomic mass of roughly 26.98 atomic mass units.

- Q: This question asks for a list of various adhesive types that are suitable for bonding aluminum sheets together.

- <p>There are several types of adhesives used for bonding aluminum sheets, including epoxy adhesives, which are strong and resistant to heat and chemicals; acrylic adhesives, known for their flexibility and UV resistance; cyanoacrylate or super glue, which offers fast bonding; polyurethane adhesives, providing excellent adhesion and durability; and silicone adhesives, which are great for high-temperature applications. Each type has its specific properties and applications, making them suitable for different bonding requirements and environmental conditions.</p>

- Q: How do you clean aluminum sheets?

- To clean aluminum sheets, you can follow a few simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum sheet. You can use a soft brush or cloth to gently sweep away any particles. 2. Prepare a cleaning solution by mixing a mild detergent or dish soap with warm water. Avoid using strong chemicals or abrasive cleaners as they can damage the aluminum. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum sheet. Make sure to cover the entire surface, paying extra attention to any stains or spots. 4. If there are stubborn stains or marks on the aluminum, you can use a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner to a soft cloth and rub gently on the affected area until the stain is removed. 5. Rinse the aluminum sheet thoroughly with clean water to remove any soap residue. This step is essential to prevent any build-up or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Make sure there is no moisture left as it can cause water spots or corrosion over time. 7. For added shine and protection, you can apply a thin layer of aluminum polish or wax. This will help to restore the luster and protect the aluminum from future tarnish or oxidation. It is important to note that the cleaning method may vary depending on the type of dirt or oxidation on the aluminum sheet. Always read and follow the manufacturer's instructions for specific cleaning recommendations.

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Aluminum sheets are generally not as strong as steel sheets, as steel has a higher tensile strength and is more rigid. However, aluminum sheets have their own advantages such as being lighter in weight, having better corrosion resistance, and being more malleable, making them suitable for certain applications where weight and flexibility are important factors.

Send your message to us

Sign Aluminum Sheets for Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords