Ceramic Filter Plate - SIC Foam Filter Plate for Molten Metal Liquid Filter High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

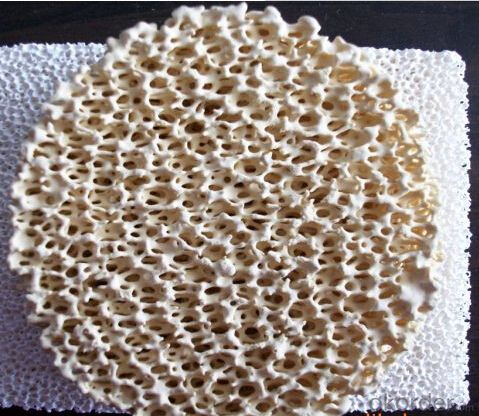

1.Production of ceramic foam filter

Ceramic Foam filters are just developed as a new type molten metal filter to decrease casting flaw in recent years. With its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance, Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, Bronze casting, etc.

2. Functions of ceramic foam filter

1). Thermal and chemical stability in high temperature,avoiding the chemical reaction with the filtered molten metal;

2). High porosity and good mechanical strength in high temperature due to its pure ceramic composite;

3). Low head loss,easy operation,energy-saving;

4). Making metal liquid flowing at stable speed and avoiding the sputtering and backset,thus increasing the surface quality of the cast part,preventing the pore disfigurement and finally lower down the unqualified rate;

5). Various sizes,shapes,apertures are available for kinds of foundry technique.

3.Physical and chemical properties

No. | Size (mm) | Flow velocity (Kg/s) | Filter capacity (Kg) | ||

Gray castiron | Ductile castiron | Gray castiron | Ductile castiron | ||

1 | 30×50×22 | 2~4 | 1~3 | 45~60 | 15~30 |

2 | 40×40×11 | 2~4 | 1~3 | 45~60 | 15~30 |

40×40×13 | 2~4 | 1~3 | 45~60 | 15~30 | |

40×40×22 | 2~4 | 1~3 | 45~60 | 15~30 | |

3 | 50×50×13 | 3~6 | 2~4 | 55~90 | 25~45 |

50×50×22 | 3~6 | 2~4 | 55~90 | 25~45 | |

4 | 60×60×22 | 4~8 | 3~5 | 65~110 | 40~75 |

5 | 66×66×22 | 5~9 | 4~6 | 80~130 | 45~80 |

6 | 75×50×22 | 4~8 | 5~7 | 65~110 | 40~75 |

7 | 75×75×22 | 9~14 | 6~9 | 145~220 | 70~100 |

8 | Φ50×22 | 3~5 | 1~3 | 50~70 | 20~40 |

9 | Φ60×22 | 3~6 | 2~4 | 65~110 | 35~60 |

10 | Φ70×22 | 4~8 | 3~6 | 75~130 | 40~75 |

11 | Φ76×22 | 5~9 | 4~7 | 90~150 | 45~80 |

12 | Φ90×22 | 10~15 | 6~9 | 180~260 | 75~110 |

13 | 100×50×22 | 8~12 | 5~8 | 130~200 | 65~90 |

14 | 100×60×22 | 9~14 | 6~9 | 180~260 | 70~100 |

15 | 150×100×22 | 18~25 | 12~16 | 300~ 400 | 150~210 |

16 | 150×150×22 | 35~50 | 24~36 | 400~ 900 | 300~450 |

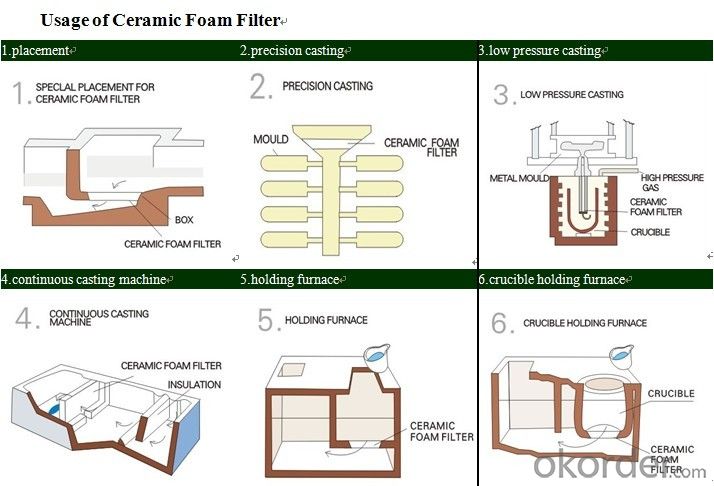

4.Usage of ceramic foam filter

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How many degrees does the ceramic filter melt?

- Alumina made from tabular corundum can be used over 1800 degrees!SiC if there is atmosphere, protection will be higher, there is no atmosphere protection, because the existence of oxidation, generally not more than 1600.Corundum, mullite, 1750 degrees small meaning.

- Q: What are the causes of the powder moisture in the ceramic filter?

- Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: Why does not the iron filter of the ceramic filter work?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- Users such as pulp size is too small, too much mud, after analysis, the following methods of testing, the results have improved, it may wish to try the following methods, perhaps of help:The vacuum degree is about -0.08MPa.Adjust spindle speed and increase drying time.Ceramic filter plate with suitable pore size range.Ceramic filter plate brand on the market range, its quality is good or bad, the feed condition itself is not an ideal situation, such as ceramic filter plate with the aperture to the mine conditions do not match, it will exacerbate the effects of poor, life is short.It can shorten the combined cleaning cycle, strengthen the cleaning effect and prolong the cleaning time.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- There may be a fault filtrate pump, diaphragm pump damage, pump mechanical seal failure, a leak, two is no output or output to the liquid, the pressure is too low, the cleaning effect is not good, the pressure is too large, will cause damage and reduce the concentration of slurry filter plate.

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- Beneficiation of ceramic filter, the technical parameters are normal, but the water will fill in groove is what reason

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

Send your message to us

Ceramic Filter Plate - SIC Foam Filter Plate for Molten Metal Liquid Filter High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords