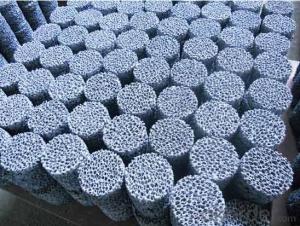

Ceramic Foam Filter Alumina for Steel& Foundry Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Alumina Ceramic Foam Filter for Foundry Industry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 30 days after receiving the downpayment |

Alumina ceramic foam filter

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Advantages:

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

Our Reputation

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- If it is found that the ceramic plate is broken, it should stop in time to replace the broken ceramic plate. Ceramic filter is produced by vacuum suction vacuum pump to the pulp in the water through the ceramic plate away, the surface aperture ceramic plate for several microns, so it can intercept the cake on the ceramic plate on the surface, if the ceramic plate is broken, a hole is a few millimeters, when the vacuum suction pump when they go together along with the pulp pump.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Generally, the vacuum degree of ceramic filter is about -0.08MPa. Sufficient vacuum pressure is only a prerequisite for a good ceramic suction effect. Besides vacuum, the other factors may affect the suction effect:Vacuum display table fault, the difference between the display value and the actual data is great.

- Q: What's the reason for high water content in filtration copper concentrate?

- Vacuum: about -0.08MPaIf the vacuum required to consider other factors; such as the vacuum degree is not up to even only about -0.05MPa, it should be related to pipeline inspection of vacuum system leakage, vacuum pump damage, distribution valve failure, ceramic plate breakage, ceramic plate connecting pipe leakage may cause the vacuum is not up to, to achieve early detection and early treatment.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- Water glass is a kind of adhesive of flotation reagent, after use may cause the pulp viscosity increased, leading to the adsorption resistance of slurry becomes large, when using ceramic filter filtration dewatering, vacuum suction surface of the microporous ceramic filter plate is smaller than the resistance, there may be a suction effect or even not suction. Some flocculant agents can lead to this phenomenon.

- Q: What is the working pressure of the ceramic filter?

- Generally speaking, there are two kinds of working pressure of ceramic filter: vacuum pressure and reverse flushing pressure.

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- There may be a failure of the filtrate pump, the diaphragm of the pump is damaged, and the mechanical seal of the pump is invalid

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

Send your message to us

Ceramic Foam Filter Alumina for Steel& Foundry Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords