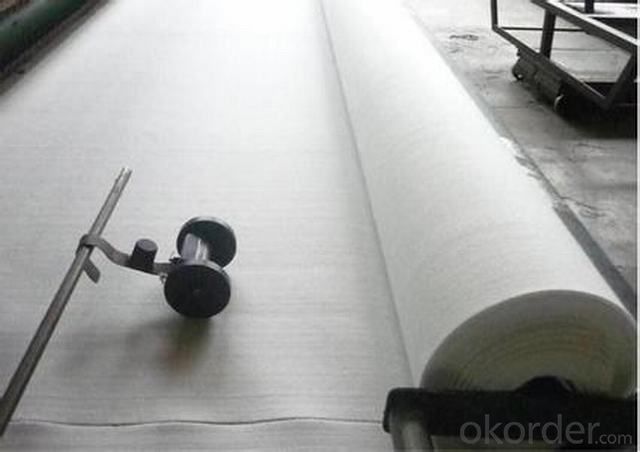

Film Géotextile Short Fiber Nonwoven Geotextile for Geotechnical Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Functions of Non-woven Geotextile for Geotechnical Engineering:

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different.granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away

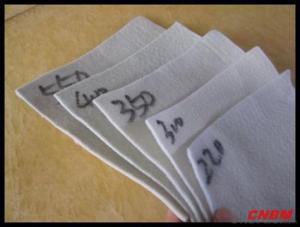

Technical Data Sheet of Short fiber Nonwoven Geotextile for Geotechnical Engineering:

Item | Art No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

Unit weight, g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

Weight tolerance, % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness, ≥mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Break strength, ≥kN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | |

CBR burst strength, ≥kN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Tear strength, ≥kN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

Width tolerance, % | -0.5 | |||||||||||

Break elongation, % | 25-100 | |||||||||||

EOS O90, mm | 0.07-0.2 | |||||||||||

Vertical permeability coefficient, cm/s | K×(10-1-10-3)K=1.0-9.9 | |||||||||||

- Q: Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q: Can concrete slabs be placed directly on geotextiles?

- Huazhi geotextile material manufacturers

- Q: Garden engineering. Do the roof of the hydrophobic board and geotextile roof, would like to know the hydrophobic board and geotextile "sub-project name" and "hidden project"

- Yue Jian professional production geotextile Wang Bin

- Q: How do geotextiles improve the performance of geocells?

- Geotextiles improve the performance of geocells by providing additional reinforcement and stability to the structure. They act as a barrier against soil erosion and help distribute loads evenly, increasing the overall strength and durability of the geocell system. Additionally, geotextiles prevent the mixing of different soil layers, enhancing filtration and drainage capabilities.

- Q: Who knows geotextile, how to sew, the best video

- Sewing machine can be sewn, you can also use hot air gun hot melt, I am specializing in the production of geotechnical materials

- Q: Geotextile production process

- 1, add polypropylene particles; 2, extrusion continuous fiber filament. Re-stretching and contraction, the fibers cut into short fiber; 3, the fiber is placed in the machine leveling; 4, continue to polymer film. The film is cut into filaments; 5, after stretching again, the filament is wound on the reel. 6, through a variety of independent research and development of the production process, the fiber for acupuncture, followed by thermal bonding. 6, through a variety of independent research and development of the production process, the fiber for acupuncture, followed by thermal bonding. Use this production process to create a geotextile with ultimate strength

- Q: Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q: How do geotextiles improve the performance of geogrids?

- Geotextiles improve the performance of geogrids by providing additional reinforcement and stability. They act as a separation layer, preventing soil particles from migrating through the geogrids and reducing the potential for clogging. Geotextiles also enhance the drainage capacity of geogrids by allowing water to flow freely through the system, preventing the accumulation of water and reducing the risk of soil erosion. Moreover, geotextiles can increase the overall strength and load-bearing capacity of geogrids, making them more efficient in stabilizing soil and improving the overall performance of geogrid applications.

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the material used, the manufacturing process, the thickness and weight of the geotextile, the orientation of the fibers, and the presence of any additives or coatings. Additionally, the installation and maintenance conditions, such as soil characteristics, temperature, moisture levels, and load distribution, can also impact the tensile strength of geotextiles.

- Q: Are geotextiles resistant to hydrostatic pressure?

- Yes, geotextiles are generally resistant to hydrostatic pressure. They are designed to allow water to pass through while providing a barrier against soil erosion and maintaining stability in various applications such as drainage systems, retaining walls, and road construction.

Send your message to us

Film Géotextile Short Fiber Nonwoven Geotextile for Geotechnical Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords