Geotextil Leroy Short Fiber Needle Punched Non Woven Geotextile 1500g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

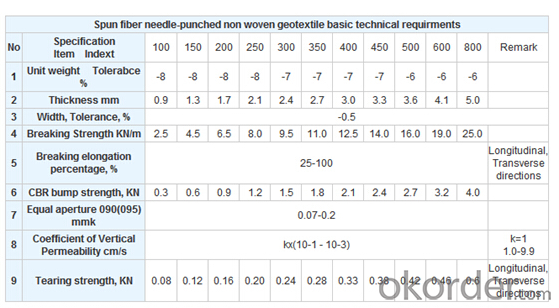

Product Specification

1. Weight: 100g~1500g

2. Width: 1m ~ 7m

Product Package:

Packing: Plastic film inside & Woven bag outside.

Shipping: About 15 days after receipt the deposit

Product Application

Product Application

Filtration

Separation

Adding

Protection

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different installation methods for geotextiles?

- There are several installation methods for geotextiles, including direct placement, trenching, and mechanical installation. In direct placement, the geotextile is simply laid over the desired area and secured in place with stakes or sandbags. Trenching involves digging a trench and placing the geotextile in the trench before backfilling. Mechanical installation utilizes specialized equipment, such as a geotextile roller or a geotextile gun, to install the geotextile quickly and efficiently. The choice of installation method depends on the specific project requirements and site conditions.

- Q: Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by providing additional stability and strength to the soil. They are placed between the soil layers to prevent erosion, and their high tensile strength helps distribute the load evenly, reducing the pressure on the retaining wall. Additionally, geotextiles promote efficient drainage, preventing water buildup behind the wall, which can further weaken the soil. Overall, geotextiles act as a barrier that enhances the overall performance and longevity of retaining walls.

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. Geotextiles are often used as a separation layer between the growing media and the drainage layer in green roof systems. They help to prevent the mixing of different layers, while still allowing water to drain through. Additionally, geotextiles can also be used to reinforce the root barrier in green roof systems, providing added stability and protection.

- Q: River slope protection geotextile unit area quality is generally how much

- Under normal circumstances is 100g - 1000g / square meter of the specifications, the actual situation is subject to special requirements, usually available geotextile unit area quality tester for testing, reference [standard group]. Test criteria: ASTM / D3776 / 2646, ISO3801, BS3424 / 2471, BSEN, M + SP65 / 65A, NEXT20

- Q: What are the design considerations for geotextile applications?

- Some of the key design considerations for geotextile applications include the required strength, filtration properties, permeability, durability, and compatibility with the surrounding environment. Additionally, factors such as installation techniques, site conditions, and project specifications must also be taken into account during the design process.

- Q: Geotextile is what material to do

- The popular understanding is that the plastic is then drawn in a variety of ways.

- Q: Can geotexters cover grass seeds?

- Yes, a lot of lawns are covered, but with dozens of grams of geotextiles are used

- Q: Google for a long time only geotextile ads! The The Do not know geotextile, drainage board such materials, in what kind of shop which has to sell? Because the building materials market to a circle, people did not sell this thing more

- I professional production of drainage board, geotextile, geomembrane and other products, wish smooth

- Q: How do geotextiles help in stabilizing slopes?

- Geotextiles help in stabilizing slopes by providing reinforcement and erosion control. They are placed on the slope surface or within the soil to increase its shear strength, prevent soil erosion, and promote water drainage. The geotextiles act as a barrier, distributing the load and reducing the risk of slope failure.

Send your message to us

Geotextil Leroy Short Fiber Needle Punched Non Woven Geotextile 1500g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords