Malla Geotextil Short Fiber Needle Punched Non Woven Geotextile 800g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geotextile, made from PP or PET, has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects.

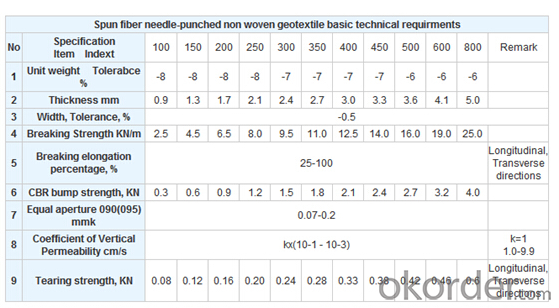

Product Specification

1. Weight: 100g~1500g

2. Width: 1m ~ 7m

Product Package:

Packing: Plastic film inside & Woven bag outside.

Shipping: About 15 days after receipt the deposit

Product Application

Product Application

Filtration

Separation

Adding

Protection

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the specifications for geotextiles used in erosion control mats?

- The specifications for geotextiles used in erosion control mats typically include factors such as the material composition, weight, tensile strength, permeability, and UV resistance. These geotextiles are designed to provide effective erosion control by stabilizing soil, preventing sediment runoff, and promoting vegetation growth.

- Q: The difference between lap and stitching

- Power and load are angular and star connection. When the power supply is connected, the phase voltage of the power supply is equal to the line voltage. The line voltage of the star load is equal to the line voltage of the power supply. The phase voltage of the load is equal to the line voltage divided by the root number. When the power supply is connected, the line voltage of the power supply is equal to three times the root number of the power supply phase voltage. The line voltage of the corner load is equal to the line voltage of the power supply, and the phase voltage is equal to the line voltage. Both at the same time using the corner, the load line voltage is equal to the power line voltage, phase voltage is equal to the line voltage. At the same time using the star, the load line voltage is equal to the power line voltage, the load phase voltage is equal to the power phase voltage, phase voltage equal to the line voltage divided by the root number three.

- Q: In ANSYS, geotextile what unit to simulate it?

- I am now doing geotextile simulation, before someone with shell63, I now use, but the shell and the physical contact I did a long time. The

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- Some of the different factors to consider for geotextile selection in agricultural applications include the required strength and durability of the geotextile, permeability and filtration properties, resistance to chemicals and biological degradation, compatibility with soil and crops, installation and maintenance requirements, and cost-effectiveness.

- Q: Geotextile 500 grams is what it means

- 500g per square meter of quality, I professional production geotextile geomembrane, wish smooth

- Q: I was just doing anti-seepage film and geotextile clerk do not know how to find this project? add me

- Ok

- Q: Can geotextiles be used in shoreline erosion control projects?

- Yes, geotextiles can be effectively used in shoreline erosion control projects. Geotextiles are permeable fabrics that can be installed along shorelines to stabilize the soil and prevent erosion caused by waves and currents. They can be used as a layer to separate the soil from the water, allowing for water filtration while reducing soil erosion.

- Q: I only know how many grams per gram of geotextile, but do not know what the meaning of this TS30? More

- Should be a product line, 30 should also be the quality of square meters you can consult the Baili Fu dealer

- Q: What are the installation techniques for geotextiles?

- There are several installation techniques for geotextiles, depending on the specific application and site conditions. Some common techniques include anchoring the geotextile with stakes or pins, securing it with sandbags or gravel, or using mechanical devices such as anchors or screws. The geotextile may also be overlapped and sewn together, or heat-welded to create a continuous barrier. It is important to follow the manufacturer's guidelines and industry standards when installing geotextiles to ensure proper functionality and longevity.

- Q: Google for a long time only geotextile ads! The The Do not know geotextile, drainage board such materials, in what kind of shop which has to sell? Because the building materials market to a circle, people did not sell this thing more

- Retail, then, to the local hardware and electrical city to see. Manufacturers of drainage board geotextile

Send your message to us

Malla Geotextil Short Fiber Needle Punched Non Woven Geotextile 800g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords