Shiny Purple Brass Aluminum Sheets for Deep Drawing Aluminium Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

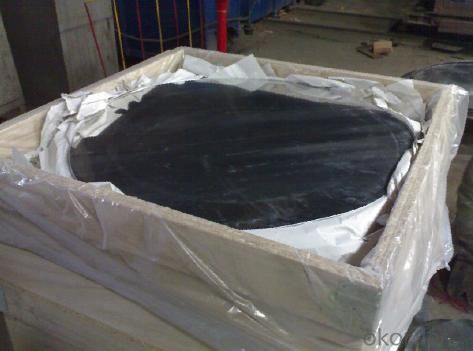

1.Structure of Aluminium Circle for Deep Drawing Aluminium Cup

Aluminium Circle for Deep Drawing Aluminium Cup is one semi-finished aluminium material. This Aluminium Circle is widly used to produce aluminium pot, especially for spinning The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Circle for Deep Drawing Aluminium Cup

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H14 | 0.2MM-2MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: A construction worker uses a steel tape to measure the length of an aluminum support column. If the measured length is 17.7 m when the temperature is 21.2°C, what is the measured length when the temperature rises to 35.4°C? (Note: Do not neglect the expansion of the steel tape. Give your answer to three decimal places.)I am really confused... Could someone solve it for me with a step-by-step explanation? Thank you so much.

- Assume linear thermal expansion with constant expansion coefficient. The change of length is given by: ΔL = L?·α·ΔT (L? initial length, α linear thermal expansion coefficient) The overall length of an object as function of temperature is: L= L? + ΔL = (1 + α·ΔT) · L? Consider the measurement at 21.2°C as reference: The aluminum column changes its length to L= (1 + α_aluminum · ΔT) · L? = (1 + 23×10-6 ^C°-1 · (35.4°C - 21.2°C) ) · 17.7m = 17.705m That would be the length measured with a steel tape at reference temperature of 21.2°C. Unfortunately the steel tape expands too. Because the scale increases with the expansion it measures too short. On the expanded tape you read the length L? while the actual length is L. Hence the measured length is: L? = L / (1 + α_steel · ΔT) = 17.705m / (1 + 11×10-6 ^C°-1 · (35.4°C - 21.2°C) ) = 17.003m

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: Are aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. They are lightweight, durable, and versatile, making them ideal for various decorative applications such as wall panels, signage, furniture accents, and more. Additionally, aluminum sheets can be easily cut, shaped, and finished to achieve the desired decorative effect, making them a popular choice among designers and architects.

- Q: How does the aluminum plate manufacturer prevent the aluminum plate from scratching?

- I also want to know how to protect the factory

- Q: What are the different bending methods for aluminum sheets?

- Aluminum sheets can be bent using different methods, each with its own advantages and limitations. Various bending techniques for aluminum sheets include: 1. Air Bending: By utilizing a punch and die, a bend is formed in the aluminum sheet without direct contact. Compressed air is employed to exert force on the sheet, resulting in the desired bend. Air bending is a versatile method that allows for a range of bend angles and radii. 2. Bottom Bending: This method involves clamping the aluminum sheet between a V-shaped die and a flat die. A punch is then used to press the sheet into the V-shaped die, creating the desired bend. Bottom bending is suitable for achieving sharp bends with small radii. 3. Coining: Precise and crisp bends are formed by applying high pressure to the aluminum sheet between a punch and a die. Coined bends exhibit minimal springback. However, this method requires specialized equipment and is typically utilized for high-volume production. 4. Roll Bending: By passing the aluminum sheet between a set of rollers, it is gradually bent into the desired shape. Roll bending is commonly employed for creating cylindrical or conical shapes. This technique can achieve large radii and is suitable for thicker aluminum sheets. 5. Press Brake Bending: This commonly used method employs a hydraulic or mechanical press brake to create bends in aluminum sheets. The sheet is clamped between a punch and a die, and the press brake applies force to create the bend. Press brake bending offers flexibility in terms of bend angles and radii. It is important to consider various factors such as the desired bend angle, radius, material thickness, and specific application requirements when selecting a bending method.

- Q: What is the surface hardness of aluminum sheets?

- The surface hardness of aluminum sheets can vary depending on the alloy and treatment, but generally, aluminum has a relatively low surface hardness compared to other metals.

- Q: What are the safety standards for using aluminum sheets in construction?

- <p>Yes, there are safety standards related to using aluminum sheets in construction projects. These standards ensure the material's structural integrity, durability, and safety. They include specifications for thickness, strength, and quality of aluminum sheets, as well as guidelines for their installation to prevent issues like corrosion, fire hazards, and structural failure. Compliance with these standards is crucial for the safety of the construction workers and the longevity of the building.</p>

- Q: What is the elongation of aluminum sheets?

- The elongation of aluminum sheets refers to the amount of stretch or deformation that the sheets can undergo before breaking or tearing. It is a measure of the material's ductility or ability to be elongated without fracturing. The elongation of aluminum sheets can vary depending on factors such as the alloy composition, tempering, and processing techniques used during manufacturing. Generally, aluminum sheets have a high elongation percentage, ranging from 15% to 40%. This means that they can be bent, formed, or stretched to a certain extent without losing their structural integrity. The elongation of aluminum sheets is an important property to consider in applications where the material needs to withstand deformation or be shaped into complex forms.

Send your message to us

Shiny Purple Brass Aluminum Sheets for Deep Drawing Aluminium Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords