Shiny Purple Brass Aluminum Sheets - Hot Rolled Aluminium Circles for Tubes AA1070

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

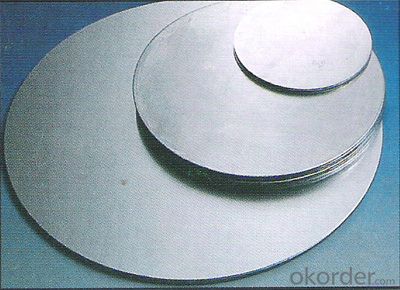

1.Structure of Hot Rolled Aluminium Circles for Tubes AA1070

Directing Pass Aluminium Strips for Secondly Rolling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Hot Rolled Aluminium Circles for Tubes AA1070

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Hot Rolled Aluminium Circles for Tubes AA1070

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1070 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage due to its durability, lightweight nature, and resistance to corrosion, making it a popular choice for a wide range of indoor and outdoor signage applications.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- It’s possible, there are several problems: 1, workers won’t wipe it thoroughly and fully, so you can wipe it after soaking. 2, the wiping efficiency is low, and we can use ultrasonic to clean it. 3, the water is poisonous and harmful to environment and workers’ health, so you can use water base to clean it, environmental and non-poisonous. Of course, if you really want to change, you can use detergent special for aluminum materials cleaning of our company, Changlvfeng chemical industry company. a, its PH value is 6.8-7.2 and it is totally an neutral liquid. b, good material applicability, detergent invented for aluminum materials. c, good degreasing ability, it has a good degreasing function for various oil contamination in processing and has no effect on material.

- Q: What does aluminum plate "3003-H24" mean?

- According to the main alloy aluminum alloy elements can be divided into 2 * * * for Al Cu alloy aluminum (Al--Cu), 3 * * * aluminum manganese alloy aluminum (Al--Mn), 4 * * * series of aluminum silicon alloy aluminum (Al--Si), 5 * * * for aluminium magnesium alloy aluminum (Al--Mg). 6 * * * for Al Mg Si alloy aluminum (AL--Mg--Si), 7 * * * for aluminum and zinc alloy aluminum [AL--Zn--Mg-- (Cu)].Aluminum status: 1, F: free machining status. 2 and O: annealed condition 3 and H: work hardening state. 4, W: solid solution heat treatment state. 5, T: heat treatment state.

- Q: My mother has this idea that when her boyfriend puts coals from the wood stove in aluminum containers to warm the house that inhaling the fumes can cause Alzheimer's disease later in life. I am just curious about the truth of it.

- yes, aluminum is seriously bad, I knew a man that worked with aluminum and he was only 26 years old and his brain went completely blank. Research it.

- Q: Is it possible to use aluminum sheets as an insulating material for walls in new construction projects?

- <p>Aluminum sheets themselves are not typically used for wall insulation due to their poor insulating properties. Aluminum is a good conductor of heat, which makes it unsuitable for insulation as it can transfer heat easily, leading to energy loss. However, aluminum can be used as a vapor barrier or as part of a composite material in combination with proper insulation. For effective insulation, materials with low thermal conductivity like fiberglass, cellulose, or foam are commonly used.</p>

- Q: How to solve the loose bonding of aluminum sheet and silica gel?

- Bonding silicone rubber needs surface treatment, after using silicone rubber surface treating agent of Kuer , you can bond them with 4211 adhesive.

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- try GOJO hand cleaner with a Sung. you dont need to scrub hard and it will remove the baked on grease.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- In the transportation industry, aluminum sheets are commonly used for various applications due to their lightweight, durability, and corrosion resistance. The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). For applications such as automotive body panels, which require a balance of weight reduction and structural integrity, aluminum sheets with thicknesses of 0.040 inches (1.02 mm) to 0.063 inches (1.6 mm) are commonly utilized. These thicknesses provide sufficient strength while keeping the weight of the vehicle lower compared to steel counterparts. In the aerospace industry, where weight reduction is of utmost importance, thinner aluminum sheets are often used. Thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are commonly employed in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is worth noting that the specific thicknesses of aluminum sheets used in the transportation industry can vary depending on the specific application, regulatory requirements, and design considerations. Therefore, it is essential to consult the relevant industry standards and specifications for precise information on the preferred thicknesses for different transportation applications.

- Q: Can aluminum sheets be used in aerospace industries?

- Aluminum sheets find frequent usage in aerospace industries. Lightweight and resistant to corrosion, aluminum proves to be an exceptional material with a remarkable strength-to-weight ratio, making it well-suited for diverse aerospace applications. Its capability to withstand elevated stress and pressure renders it valuable in the construction of aircraft structures, including wings, fuselage, and landing gear. Moreover, aluminum sheets possess malleability, allowing for the creation of intricate shapes that contribute to the requisite design flexibility within the aerospace sector. However, it is worth noting that aluminum alloys, rather than pure aluminum, are typically employed in aerospace applications due to their augmented mechanical properties and superior performance.

- Q: Can aluminum sheets be painted or coated with different colors?

- Aluminum sheets are capable of being painted or coated in a variety of colors. The versatility of aluminum as a material makes it easy to achieve the desired aesthetic through painting or coating. To paint or coat aluminum, a layer of paint or coating material is applied onto the sheet's surface. This can be accomplished through spraying, rolling, or dipping methods. The paint or coating adheres to the aluminum, creating a protective layer while altering its color or finish. The ability to paint or coat aluminum sheets in different colors provides limitless opportunities for customization and design possibilities.

Send your message to us

Shiny Purple Brass Aluminum Sheets - Hot Rolled Aluminium Circles for Tubes AA1070

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords