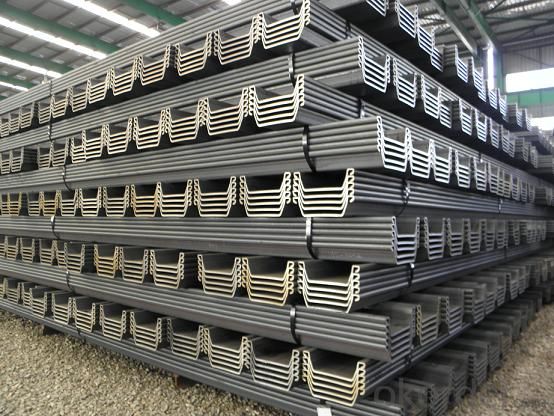

U profile Sheet Pile WRU

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of U profile Sheet Pile WRU:

Type | Width | Height | Thickness | Sectional area | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Cm2/m | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRU7-750 | 750 | 320 | 5 | 71.8 | 42.3 | 56.4 | 11089 | 693 |

WRU7-900 | 900 | 320 | 5 | 68.2 | 48.2 | 53.5 | 11308 | 706 |

WRU7-850 | 850 | 320 | 5 | 69.4 | 46.3 | 54.5 | 11244 | 703 |

WRU8-750 | 750 | 320 | 6 | 86.1 | 50.7 | 67.6 | 13191 | 824 |

WRU8-850 | 850 | 320 | 6 | 83 | 55.4 | 65.2 | 13379 | 836 |

WRU8-900 | 900 | 320 | 6 | 81.8 | 57.8 | 64.2 | 13458 | 841 |

WRU9-750 | 750 | 320 | 7 | 100 | 58.9 | 78.5 | 15256 | 953 |

WRU9-850 | 850 | 320 | 7 | 96.5 | 64.4 | 75.8 | 15478 | 967 |

WRU9-600 | 600 | 320 | 7 | 108.3 | 50.7 | 85 | 14783 | 924 |

WRU9-900 | 900 | 320 | 7 | 95 | 67.1 | 74.6 | 15571 | 973 |

WRU10-700 | 700 | 310 | 9 | 129.6 | 71.2 | 101.7 | 16270 | 1049 |

WRU10-1050 | 1050 | 310 | 9 | 116.2 | 95.8 | 91.2 | 17644 | 1138 |

WRU10-450 | 450 | 360 | 8 | 147.7 | 52.2 | 116 | 18267 | 1015 |

WRU11-575 | 575 | 360 | 8 | 133.1 | 60.1 | 104.5 | 19684 | 1094 |

WRU11-600 | 600 | 360 | 8 | 131 | 61.7 | 102.8 | 19897 | 1105 |

WRU 900×360×8 | 114.4 | 80.9 | 89.8 | 21526 | 1195 | |||

WRU11-450 | 450 | 360 | 9 | 167 | 59 | 131.1 | 20383 | 1132 |

WRU12-575 | 575 | 360 | 9 | 149.5 | 67.5 | 117.5 | 21979 | 1221 |

WRU12-600 | 600 | 360 | 9 | 147 | 69.2 | 115.4 | 22219 | 1234 |

WRU 900×360×9 | 128.5 | 90.8 | 100.9 | 24054 | 1336 | |||

WRU12-450 | 450 | 360 | 10 | 181.8 | 64.2 | 142.7 | 22443 | 1247 |

WRU13-575 | 575 | 360 | 10 | 163.8 | 73.9 | 128.6 | 24223 | 1346 |

WRU13-600 | 600 | 360 | 10 | 161.3 | 76 | 126.6 | 24491 | 1361 |

WRU 900×360×10 | 141.8 | 100.2 | 111.3 | 26538 | 1474 | |||

WRU16-650 | 650 | 480 | 8 | 138.3 | 70.6 | 108.6 | 39872 | 1661 |

WRU16-750 | 750 | 480 | 8 | 130.6 | 76.9 | 102.5 | 40496 | 1687 |

WRU18- 600 | 600 | 350 | 12 | 219 | 103.1 | 171.9 | 32797 | 1874 |

WRU18- 950 | 950 | 350 | 12 | 182.5 | 136.1 | 143.3 | 33346 | 1906 |

WRU 18-650 | 650 | 480 | 9 | 154.7 | 78.9 | 121.4 | 44521 | 1855 |

WRU18-750 | 750 | 480 | 9 | 146.1 | 86 | 114.7 | 45241 | 1885 |

WRU20- 600 | 600 | 350 | 13 | 238.5 | 112.3 | 187.2 | 35224 | 2013 |

WRU20 | 650 | 540 | 8 | 153.7 | 78.1 | 120.2 | 56002 | 2074 |

WRU23-650 | 650 | 540 | 9 | 170 | 86.8 | 133.5 | 62588 | 2318 |

WRU23-750 | 750 | 540 | 10 | 175.9 | 103.5 | 138.1 | 61340 | 2272 |

WRU26 | 650 | 540 | 10 | 187.5 | 95.7 | 147.2 | 69093 | 2559 |

WRU30-700 | 700 | 560 | 11 | 215.8 | 118.6 | 169.4 | 83813 | 2993 |

WRU30-750 | 750 | 560 | 11 | 208.7 | 122.9 | 163.8 | 83752 | 2991 |

WRU32-700 | 700 | 560 | 12 | 234.5 | 128.9 | 184.1 | 90880 | 3246 |

WRU32-750 | 750 | 560 | 12 | 227 | 133.6 | 178.2 | 90828 | 3244 |

WRU35-700 | 700 | 562 | 13 | 245.3 | 144.3 | 192.5 | 98607 | 3509 |

WRU36-700 | 700 | 558 | 14 | 284.3 | 156.2 | 223.2 | 102145 | 3661 |

WRU39-700 | 700 | 560 | 15 | 303.8 | 166.9 | 238.5 | 109655 | 3916 |

WRU41-700 | 700 | 562 | 16 | 323.1 | 177.6 | 253.7 | 117194 | 4170 |

WRU 32 | 750 | 598 | 11 | 215.9 | 127.1 | 169.5 | 97362 | 3265 |

WRU 35 | 750 | 600 | 12 | 234.9 | 138.3 | 184.4 | 106416 | 3547 |

WRU 38 | 750 | 602 | 13 | 253.7 | 149.4 | 199.2 | 115505 | 3837 |

WRU 40 | 750 | 598 | 14 | 282.2 | 166.1 | 221.5 | 119918 | 4011 |

WRU 43 | 750 | 600 | 15 | 301.5 | 177.5 | 236.7 | 128724 | 4291 |

WRU 45 | 750 | 602 | 16 | 320.8 | 188.9 | 251.8 | 137561 | 4570 |

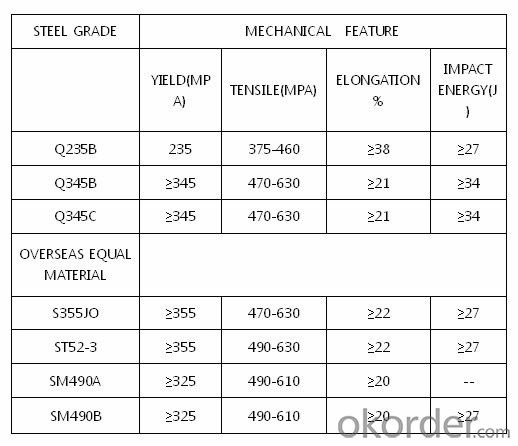

Steel Grade for Sheet Pile

Usage and Applications of U profile Sheet Pile WRU:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

Advantage of U profile Sheet Pile WRU:

U sheet pile is a service-proven type familiar to both designers and constructors, which is extensively used for permanent structures, temporary earth-retaining works and temporary cofferdams, etc

In addition to its rigid structure, its moment of inertia per pile is relatively large, thus allowing repetitive use

Available in a range of sections, with section modulus values ranging from 456 to 4042 cm3/m

- Q: How is steel used in the production of medical devices?

- Steel is used in the production of medical devices due to its strength, durability, and resistance to corrosion. It is commonly used for manufacturing surgical instruments, implants, and various medical equipment such as scalpel blades, forceps, needles, and stents. The properties of steel make it ideal for these applications as it provides reliability, precision, and ease of sterilization, ensuring the safety and effectiveness of medical devices used in patient care.

- Q: What are the different types of steel bars and their uses?

- There are several different types of steel bars, each with their own unique properties and uses. Some common types include mild steel bars, high-strength deformed bars, stainless steel bars, and alloy steel bars. Mild steel bars are widely used in construction for their affordability and versatility. High-strength deformed bars are commonly used in reinforced concrete structures to provide extra strength and durability. Stainless steel bars are corrosion-resistant and often used in applications where hygiene and aesthetics are important, such as in the food industry or architectural projects. Alloy steel bars, on the other hand, are made by adding various elements to enhance their strength, hardness, and resistance to wear. They find applications in machinery, automotive, and aerospace industries, among others. Overall, the choice of steel bar depends on the specific requirements of the project and the desired characteristics needed for its intended use.

- Q: What are the different types of steel fencing and barriers available?

- There are various types of steel fencing and barriers available, including chain link fences, wrought iron fences, steel picket fences, steel mesh fences, and steel bollards. Each type offers unique features and benefits, catering to different security and aesthetic requirements.

- Q: How is steel wire galvanized for fencing applications?

- Steel wire is galvanized for fencing applications through a process known as hot-dip galvanization. In this process, the steel wire is cleaned to remove any impurities and then dipped into a molten zinc bath. The wire is completely coated with a layer of zinc, which provides corrosion resistance and durability. This galvanized steel wire is then used for manufacturing fencing products that can withstand harsh environmental conditions and extend their lifespan.

- Q: What are the different types of steel scaffolding systems?

- There are several types of steel scaffolding systems, including tube and coupler scaffolding, system scaffolding, and frame scaffolding. Tube and coupler scaffolding consists of tubes and couplers that are connected together to form a stable structure. System scaffolding uses pre-designed components that can be easily assembled and dismantled, providing flexibility and efficiency. Frame scaffolding is made up of frames and cross braces, offering a simple and sturdy solution for construction projects.

- Q: What are the applications of steel in the wastewater treatment industry?

- Steel is widely used in the wastewater treatment industry for various applications. It is used to construct tanks and vessels that hold wastewater, as steel is highly durable, corrosion-resistant, and can withstand harsh environmental conditions. Steel is also used in the construction of piping systems, pumps, and valves, ensuring efficient transportation and control of wastewater. Additionally, steel is employed in the manufacturing of screening and filtration equipment, which helps remove solid waste from wastewater. Overall, the applications of steel in the wastewater treatment industry contribute to the effectiveness and longevity of the treatment processes.

- Q: How are steel tubes used in plumbing and HVAC systems?

- Steel tubes are commonly used in plumbing and HVAC systems due to their durability and strength. They are utilized for transporting water, gas, and other fluids within the building. Steel tubes are also used for the distribution of hot and cold air in HVAC systems. Their resistance to rust and corrosion makes them an ideal choice for these applications, ensuring longevity and reliability in plumbing and HVAC systems.

- Q: How is steel wire galvanized for electrical applications?

- Steel wire is galvanized for electrical applications by dipping it into a bath of molten zinc or by electroplating it with a zinc coating. This process creates a protective layer on the surface of the wire, preventing corrosion and enhancing its conductivity for electrical purposes.

- Q: How is steel pipe welded for structural applications?

- Steel pipe is commonly welded for structural applications using various welding techniques such as electric resistance welding (ERW), submerged arc welding (SAW), or gas metal arc welding (GMAW). These methods involve applying heat and pressure to join two or more sections of steel pipe together, ensuring a strong and durable bond.

- Q: How is steel used in the production of machinery and equipment?

- Steel is widely used in the production of machinery and equipment due to its strength, durability, and versatility. It is used to manufacture various components such as frames, casings, gears, and bearings, providing the necessary structural integrity and mechanical capabilities. Steel's ability to withstand high temperatures, corrosion, and heavy loads makes it ideal for applications in heavy machinery, construction equipment, automotive industry, and many other sectors.

Send your message to us

U profile Sheet Pile WRU

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords