Straight Web Steel Sheet Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Straight Web Steel Sheet Pile:

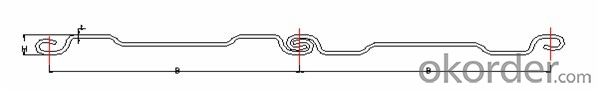

Profile | Width B mm | Height H mm | Thickness T mm | Section area A cm2/m

| Mass G | Moment of Inertia cm4/m | Section Modulus cm3/m | |

Per pile kg/m

| Per wall kg/m2

| |||||||

WRX 600-10 | 600 | 60 | 10.0 | 144.8 | 68.2 | 113.6 | 396 | 132 |

WRX 600-11 | 600 | 61 | 11.0 | 158.5 | 74.7 | 124.4 | 435 | 143 |

WRX 600-12 | 600 | 62 | 12.0 | 172.1 | 81.1 | 135.1 | 474 | 153 |

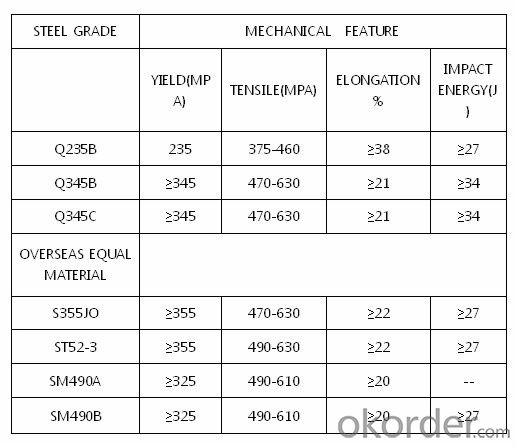

Steel Grade for Sheet Pile

Usage and Applications of Straight Web Steel Sheet Pile:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q: What are the different types of steel sections used in industrial structures?

- There are several types of steel sections commonly used in industrial structures, including I-beams, H-beams, channels, angles, and T-sections. These sections are chosen based on their structural properties, such as load-bearing capacity and resistance to bending. Each section has its own unique shape and dimensions, allowing for efficient distribution of weight and optimal structural integrity in various applications.

- Q: How are steel gratings used in the construction of walkways and platforms?

- Steel gratings are commonly used in the construction of walkways and platforms as they provide a durable and safe flooring solution. The interlocking steel bars create a sturdy surface that can support heavy loads and withstand constant foot traffic. Additionally, the openings between the bars allow for drainage, preventing the accumulation of water or debris. This ensures a slip-resistant surface, making steel gratings an ideal choice for outdoor and industrial environments.

- Q: What are the advantages of using steel in high-rise buildings?

- There are several advantages of using steel in high-rise buildings. Firstly, steel has a high strength-to-weight ratio, allowing for lighter and more efficient structural designs. This, in turn, reduces the overall weight of the building and enhances its stability and safety. Secondly, steel is a highly durable material that can withstand extreme weather conditions, earthquakes, and fire, making it ideal for tall buildings. Additionally, steel's flexibility allows for easy modifications and expansions in the future, ensuring adaptability and longevity of the structure. Lastly, steel is a sustainable and recyclable material, promoting environmental consciousness and reducing construction waste.

- Q: How do steel products contribute to the construction of theaters and concert halls?

- Steel products contribute to the construction of theaters and concert halls in various ways. Firstly, steel is widely used for the structural framework of these buildings, providing strength and support. It allows for large open spaces, accommodating the grand designs and unique architectural features often found in these venues. Additionally, steel is used for the fabrication of trusses, beams, and columns, ensuring stability and durability. Its versatility enables the creation of intricate designs, such as curved or cantilevered structures, enhancing the aesthetic appeal of these cultural spaces. Moreover, steel is a fire-resistant material, providing safety measures to protect both the building and its occupants. Overall, steel products play a vital role in constructing theaters and concert halls, facilitating their artistic and functional requirements.

- Q: What are the different types of steel fittings and their applications?

- There are several types of steel fittings commonly used in various applications. Some of the most common types include threaded fittings, flanged fittings, welded fittings, and compression fittings. Threaded fittings, as the name suggests, have threads on the inner or outer surface, allowing them to be easily screwed onto pipes or other fittings. They are commonly used in plumbing systems and are known for their convenience and easy installation. Flanged fittings, on the other hand, have flanges that can be bolted together, providing a secure and leak-proof connection. These fittings are often used in industries like oil and gas, chemical processing, and water treatment, where high-pressure and high-temperature applications require reliable connections. Welded fittings are created by welding steel pieces together, resulting in a permanent and strong joint. They are commonly used in pipelines and structural applications, where a continuous and leak-proof connection is crucial. Compression fittings are designed to create a tight seal by compressing a ferrule or sleeve onto the pipe. These fittings are widely used in plumbing systems for connecting copper, PVC, or stainless steel pipes. Overall, the choice of steel fitting depends on the specific application requirements, such as pressure, temperature, and the type of fluid or gas being transported. Each type of fitting has its own advantages and limitations, and it's essential to select the appropriate fitting to ensure a safe and efficient system.

- Q: What are the advantages of using steel wire ropes?

- There are several advantages of using steel wire ropes. Firstly, steel wire ropes have high strength and durability, making them suitable for heavy lifting and pulling tasks. They can handle high loads and provide excellent resistance to wear and tear. Secondly, steel wire ropes have excellent flexibility, allowing them to be used in various applications and easily maneuvered around corners and obstacles. Thirdly, steel wire ropes have a long lifespan, requiring less frequent replacements compared to other materials. Lastly, steel wire ropes have high resistance to corrosion, making them suitable for outdoor and marine environments.

- Q: What are the different types of steel scaffolding systems?

- There are several types of steel scaffolding systems, including frame scaffolding, tube and clamp scaffolding, system scaffolding, and suspended scaffolding. Frame scaffolding consists of vertical frames connected by horizontal and diagonal braces, providing a stable structure. Tube and clamp scaffolding uses steel tubes and clamps to create a flexible and adjustable system. System scaffolding utilizes prefabricated components, such as modular frames and braces, for quick assembly and versatility. Suspended scaffolding is suspended from the roof or other elevated structure, allowing workers to access hard-to-reach areas.

- Q: How do steel products contribute to the agricultural and farming sector?

- Steel products contribute to the agricultural and farming sector in various ways. Firstly, steel is used to manufacture durable and strong equipment such as tractors, plows, and harvesters, which help increase efficiency and productivity on farms. Additionally, steel is utilized in building structures like barns, sheds, and storage facilities, providing a sturdy and long-lasting shelter for livestock and crops. Moreover, steel is essential for irrigation systems, fencing, and machinery parts, ensuring the smooth operation of agricultural activities. Overall, steel products play a crucial role in enhancing the effectiveness, safety, and sustainability of the agricultural and farming sector.

- Q: What are the applications of steel gratings in oil refineries?

- Steel gratings are commonly used in oil refineries for various applications such as platforms, walkways, stair treads, handrails, and drainage covers. They provide a strong and durable flooring solution that can withstand heavy loads, corrosive environments, and high temperatures. Steel gratings also offer excellent drainage properties, allowing for the efficient removal of liquids and debris, and they provide a non-slip surface for enhanced safety in oil refinery facilities.

- Q: What are the applications of stainless steel in the food industry?

- Stainless steel is widely used in the food industry due to its numerous beneficial properties. It is commonly used for equipment and surfaces that come into contact with food, such as food processing machinery, countertops, sinks, and storage containers. Stainless steel is preferred in the food industry because it is corrosion-resistant, easy to clean and maintain, and highly hygienic. It does not react with food or alter its taste, ensuring the integrity and safety of the products. Additionally, stainless steel is durable, heat-resistant, and can withstand extreme temperatures, making it suitable for a wide range of food processing applications.

Send your message to us

Straight Web Steel Sheet Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords