Z profile Sheet Pile WRZ

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Z profile Sheet Pile WRZ:

Type | Width | Height | Thickness | Sectional area | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Cm2/m | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRZ5-850 | 850 | 253 | 5 | 61.2 | 40.8 | 48.0 | 6416 | 507 |

WRZ6-850 | 850 | 254 | 6 | 73.2 | 48.9 | 57.5 | 7671 | 604 |

WRZ10-700 | 700 | 350 | 5 | 75.9 | 41.7 | 59.6 | 17208 | 983 |

WRZ12-650 | 650 | 319 | 7 | 113.2 | 57.8 | 88.9 | 19603 | 1229 |

WRZ14-650 | 650 | 320 | 8 | 128.9 | 65.8 | 101.2 | 22312 | 1395 |

WRZ16-635 | 635 | 379 | 7 | 122.5 | 61 | 96.1 | 30502 | 1610 |

WRZ18-635 | 635 | 380 | 8 | 139.6 | 69.6 | 109.6 | 34717 | 1827 |

WRZ18A-685 | 685 | 401 | 9 | 142.8 | 76.8 | 112.1 | 37335 | 1862 |

WRZ20-685 | 685 | 402 | 10 | 158.4 | 158.4 | 158.4 | 158.4 | 158.4 |

WRZ22-635 | 635 | 417 | 9 | 162.6 | 81 | 127.6 | 47225 | 2265 |

WRZ25-635(平) | 635 | 418 | 10 | 179.5 | 89.5 | 141 | 52258 | 2500 |

WRZ25-635(弯) | 635 | 418 | 10 | 189.3 | 94.4 | 148.6 | 52258 | 2500 |

WRZ28-635 | 635 | 419 | 11 | 207.9 | 103.6 | 163.2 | 58786 | 2806 |

WRZ30-635 | 635 | 420 | 12 | 226.2 | 112.8 | 177.5 | 63889 | 3042 |

WRZ30-700 | 700 | 449 | 11 | 202.9 | 111.5 | 159.3 | 67025 | 2986 |

WRZ32-635 | 635 | 421 | 13 | 245.4 | 122.3 | 192.7 | 68954 | 3276 |

WRZ34-675 | 675 | 490 | 12 | 222.2 | 117.8 | 174.4 | 84657 | 3455 |

WRZ37-675 | 675 | 491 | 13 | 242.3 | 128.4 | 190.2 | 91327 | 3720 |

WRZ38-675 | 675 | 491.5 | 13.5 | 249.6 | 132.3 | 196 | 94699 | 3853 |

WRZ40-675 | 675 | 492 | 14 | 258.4 | 136.9 | 202.9 | 98065 | 3984 |

WRZ47-700 | 700 | 549 | 14 | 269 | 147.8 | 211.2 | 129356 | 4712 |

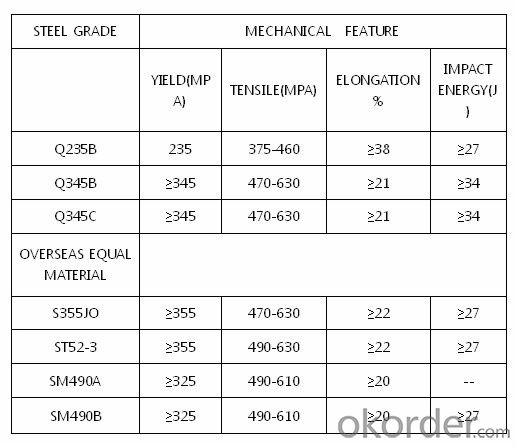

Steel Grade for Sheet Pile

Usage and Applications of Z profile Sheet Pile WRZ:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

Advantage of Z profile Sheet Pile WRZ:

Ø Excellent properties with high tensile strength

Ø Capable of saving steels economically

Ø Extremely competitive section modulus

Ø High installation performance with large width

- Q: What are the properties of stainless steel for medical applications?

- Stainless steel used in medical applications is known for its exceptional properties such as corrosion resistance, high strength, durability, and biocompatibility. These properties make it an ideal material for surgical instruments, implants, and medical devices. Additionally, stainless steel can be easily sterilized, has good formability, and allows for precise manufacturing, making it a reliable choice in the medical field.

- Q: How is steel used in the construction of stadiums and arenas?

- Steel is commonly used in the construction of stadiums and arenas due to its strength and durability. It is used to create the framework and support structures, such as beams, columns, and trusses, that can withstand heavy loads and provide stability. Steel is also used in the construction of roofs, façades, and seating structures, as it allows for large open spaces, flexibility in design, and efficient construction. Overall, steel plays a critical role in ensuring the safety, strength, and longevity of stadiums and arenas.

- Q: What are the common uses of steel in the aerospace industry?

- Steel is commonly used in the aerospace industry for various applications including the construction of airframes, engine components, landing gears, and fasteners. It offers excellent strength-to-weight ratio, durability, and resistance to high temperatures, making it ideal for withstanding the demanding conditions of aerospace operations.

- Q: How does the thickness of steel affect its strength?

- The thickness of steel directly affects its strength. Generally, thicker steel tends to be stronger as it can withstand greater force and load without deformation or failure. Thicker steel also provides better resistance against bending, breaking, or warping under stress. However, it is worth noting that there is an optimal thickness range for each specific application, where steel is neither too thin to compromise strength nor too thick to become impractical or excessively heavy.

- Q: What are the different types of steel fasteners and their uses in the marine industry?

- In the marine industry, there are several types of steel fasteners commonly used. These include stainless steel fasteners, galvanized steel fasteners, and titanium fasteners. Stainless steel fasteners are highly resistant to corrosion and are suitable for use in environments with high levels of moisture and saltwater exposure. They are often used in marine applications such as boat building, dock construction, and offshore structures. Galvanized steel fasteners are coated with a layer of zinc to provide corrosion resistance. They are commonly used in marine applications where stainless steel might be too expensive or unnecessary, such as in non-submerged parts of boats or in marine infrastructure projects. Titanium fasteners are lightweight, yet incredibly strong and corrosion-resistant. They are commonly used in high-performance marine applications, such as racing yachts or other vessels that require components with exceptional strength-to-weight ratios. Overall, the selection of steel fasteners in the marine industry depends on the specific requirements of the project, the level of exposure to saltwater and moisture, as well as factors such as cost and performance.

- Q: How can steel products be recycled?

- Steel products can be recycled by first collecting and sorting them from other waste materials. The collected steel is then cleaned and processed to remove impurities. It is then melted down in a furnace and transformed into new steel products, which can be used in various industries. This recycling process helps conserve natural resources, reduce energy consumption, and minimize environmental pollution.

- Q: What are the different types of steel profiles and their uses?

- There are various types of steel profiles, including I-beams, H-beams, channels, angles, and tubes. I-beams are commonly used in construction for their strength and load-bearing capabilities. H-beams are similar to I-beams but have thicker flanges, making them suitable for heavy-duty applications. Channels are often used for structural support or as track systems. Angles are commonly used for framing structures or as brackets. Tubes can be used for various purposes, such as pipe fittings or structural components. Each type of steel profile has its own unique uses and applications in different industries.

- Q: What is the process of galvanizing steel?

- The process of galvanizing steel involves immersing the steel in a bath of molten zinc, ensuring a protective coating is formed on its surface. This coating provides excellent corrosion resistance, making the steel more durable and extending its lifespan.

- Q: How are steel bars used in the reinforcement of bridges and flyovers?

- Steel bars are used in the reinforcement of bridges and flyovers to provide strength and stability to the structures. These bars are typically inserted into the concrete during construction to enhance the load-bearing capacity and prevent any potential cracking or failure. The steel bars, also known as rebar, act as a framework within the concrete, absorbing and distributing the loads and forces generated by the bridge or flyover, thus ensuring their structural integrity and durability.

- Q: What are the different types of steel mesh and their applications?

- There are several different types of steel mesh, each with its own specific applications. Some common types include welded wire mesh, expanded metal mesh, and woven wire mesh. Welded wire mesh is commonly used in construction and industrial settings for reinforcement, fencing, and concrete reinforcement. Expanded metal mesh is often used for architectural and decorative purposes, as well as in filtration systems and security applications. Woven wire mesh is versatile and can be used in various industries, including agriculture, mining, and transportation, for purposes such as screening, separation, and containment.

Send your message to us

Z profile Sheet Pile WRZ

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords