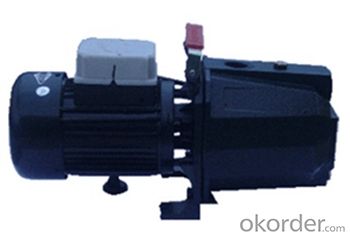

Self-priming Surface Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

JET pumps are with an automatic ejector system, widely used in domestic applications, gardens and supply water

2. Construction

Pump Body: Cast Iron/Stainless Steel/Brass

Front Cover: Cast Iron/Cast Iron with brass insert / Aluminum

Impeller: Brass/Aluminum/PPO

Mechanical Seal: Carbon/Ceramic/Stainless Steel

Motor Housing: Alloy Aluminum

Shaft: Carbon Steel/Stainless Steel/High Frequency Wedding Shaft

Insulation: Class B / Class F

Protection: IP44 / IP54

Cooling: External Ventilation

With Thermal Overload protector in single phase motor.

3. Operation Conditions

Suction head up to 9M

Liquid temperature up to 60C

Ambient temperature up to 40C

Max.Pressure:9Bar

4. FAQ

1) Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2) Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3) Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

- Q: What is a solution pump?

- 2.1 advantages of canned pumps(1) fully enclosed. There is no dynamic seal in the structure. Only the static seal in the outer shell of the pump can be made without leakage. It is especially suitable for transporting flammable, explosive, precious liquids and toxic, corrosive and radioactive liquids(2) high safety. The rotor and stator each have a shielding sleeve, so that the rotor and stator of the motor are not in contact with the material, even if the shield is broken, it will not produce the risk of leakage and leakage(3) compact structure and small footprint, the pump and motor is a whole, disassembly and assembly do not need to find the center. The base and foundation requirements are low, and the daily maintenance workload is low, and the maintenance cost is low

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- The role of the check valve:"[the water pump impeller is not closed" refers to the pump suction pump before the water without water inlet pipe and water outlet pipe gas should be connected] is a connector, a connector, still can make the level surface, in order to prevent the water flow along the pipe, until it reaches the level of the flush, then increased check valve, or pumping up water will not leak?Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".....

- Q: What are the causes of pump shock?

- 6., water pump relatively serious cavitation, improve the water level of the water tank, reduce water output7., impeller and motor rotor imbalance, overhaul8. pump shaft bending or abrasion overhaul

- Q: Does vacuum pump oil belong to dangerous goods?

- Is the grease inside? How could it be dangerous goods? Absolutely not!

- Q: What are the basic technical parameters of the pump?

- Two, pump head H head is the unit weight of the liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid. Habits referred to as meters. Three, the pump speed is n RPM pump unit time revolutions, represented by the symbol n, the unit is r/min. four, the pump NPSH NPSH NPSH is also called net positive suction head, said main parameters of cavitation performance. Cavitation has been used a h power of five, the power of the pump. And the efficiency of the pump is usually refers to the input power, which is the prime mover on the pump shaft power, it is also known as the shaft power, denoted by P;

- Q: Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- Select the hydraulic pump from the following considerations:1. hydraulic pump pressureHydraulic pump operating pressure is the pump (or motor) in actual work output (or input) oil pressure, determined by the external load.Rated pressure refers to the maximum pressure under continuous running in accordance with the test standards under normal working conditions. The size of the pump is limited by the service life, and the service life of the pump (or motor) will be shorter than the design life if it exceeds the rated pressure. When the work pressure is greater than the rated pressure, it is called overload.

- Q: What is the working pressure of the hydraulic pump in the hydraulic transmission system?

- The operating pressure of the hydraulic system depends mainly on the load. Generally speaking, the working pressure of the hydraulic system means the highest working pressure of the system. If the pressure is higher than the value of the equipment, the relief valve works to relieve pressure. The actual working pressure of the hydraulic system is determined by the load, which refers to the actual pressure of the hydraulic oil and can be read directly from the pressure gauge. The pressure increases with the increase of the load. You Li's balance can know: the thrust of the cylinder = the load, the thrust of the cylinder = the working pressure of the hydraulic oil, the working area of the cylinder, the working pressure = the load / the area of the cylinder.

- Q: Water pump spoon pipe for power plantWhich hero can tell me what is the water pump spoon tube ah? And its role

- Then control the speed level, to achieve the purpose of regulating the speed and flow of the feed water pump.

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- The valve opening pump is aimed at the centrifugal pump.From the power curve of the centrifugal pump, the power of the centrifugal pump increases with the increase of the flow rate; the flow curve of the centrifugal pump shows that the flow rate of the centrifugal pump decreases with the increase of the head.

- Q: Attention should be paid to the use of pumps?

- To carefully check whether there is a crack impeller, impeller fixed in the bearings are loose, if there are cracks and loose, hungry phenomenon should be promptly repaired, if the pump impeller above the soil should also be cleaned

Send your message to us

Self-priming Surface Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords