Self-Adhesive Bitumen Coated Fiberglass Geogrid Geocells for Driveways

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with Self-adhesive Bitumen Coated

Description Of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

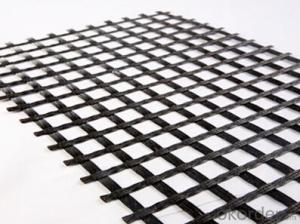

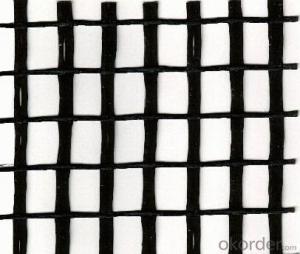

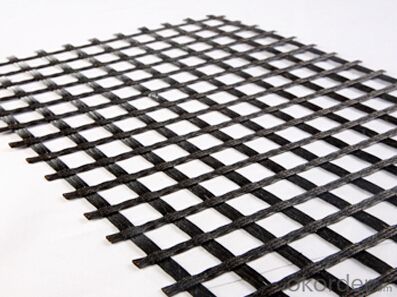

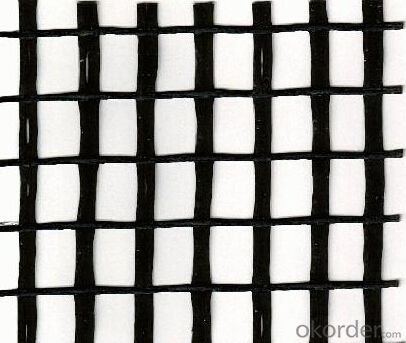

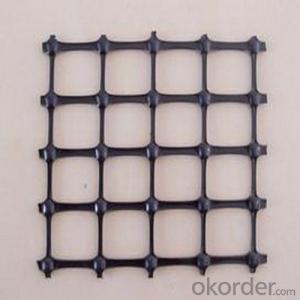

IMages of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

FAQ of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to enhance stability, increase load-bearing capacity, and prevent soil erosion. They help to distribute the load more evenly, improve the overall structural integrity, and provide additional support to the landfill liner system.

- Q: Can geogrids be used in retaining walls for industrial facilities?

- Yes, geogrids can be used in retaining walls for industrial facilities. Geogrids are commonly used in the construction of retaining walls to enhance stability, improve soil reinforcement, and provide long-term durability. Industrial facilities often require sturdy and reliable retaining walls to support heavy loads and ensure the safety of the structure. Geogrids offer an effective solution by distributing the forces exerted on the retaining wall and preventing soil erosion, thereby improving the overall performance and longevity of the wall in industrial settings.

- Q: Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. They provide excellent tensile strength and stability to the soil, helping to distribute loads and prevent soil movement or settlement. Geogrids are specifically designed to enhance soil performance and can effectively reinforce the soil around pipelines, ensuring their stability and longevity.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing structural reinforcement and stability. They help to distribute the loads and forces acting on the geotextile tubes, preventing deformation and maintaining their shape. This reinforcement improves the overall strength and durability of the geotextile tubes, making them more effective in applications such as erosion control, shoreline protection, and sediment containment.

- Q: How to apply the fixed scale of Geogrid

- Remove the geogrid as long as you take the reinforcement of things, such as U type nails, packing belt, gasket, steel nails and other reinforcement, and then roll up on it.

- Q: What are the application of Geogrid in the construction of cement concrete pavement

- On the basis of the surface of a layer of geogrid poured concrete

- Q: What are the design considerations for geogrids in reinforced soil slopes?

- Some important design considerations for geogrids in reinforced soil slopes include the type and strength of the geogrid material, the required tensile strength and stiffness of the geogrid, the appropriate spacing and orientation of the geogrid layers, the connection details and anchorage methods for the geogrids, and the overall stability and safety of the reinforced slope. Other factors to consider include the soil properties, slope geometry, and potential loads or forces acting on the slope. Additionally, proper installation and construction techniques should be considered to ensure the effectiveness and durability of the geogrid reinforcement system.

- Q: What are the design considerations for geogrid reinforcement?

- Some design considerations for geogrid reinforcement include the type and strength of the geogrid material, the required level of soil stabilization, the anticipated loads and stresses on the reinforced soil structure, and the desired lifespan of the structure. Other factors to consider include soil characteristics, installation and construction procedures, and environmental conditions. Additionally, the design should account for factors such as slope stability, drainage, and potential settlement.

- Q: Building houses and roads require pipes and geotextile, grille?

- The outstanding advantages of polythylene unixial geogrid deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project. This product is suitable for the construction of roads, railways and rivers and lakes along the coast of reinforced retaining walls, dams, bridges, steep slopes and geocell

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- It has a unique performance and efficacy. Geogrid is often used as reinforcement of reinforced soil structure or composite material

Send your message to us

Self-Adhesive Bitumen Coated Fiberglass Geogrid Geocells for Driveways

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords