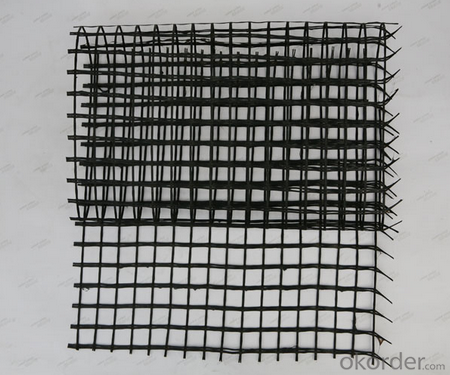

Geocells for Driveways - Fiberglass Geogrid with Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

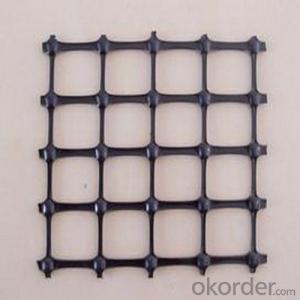

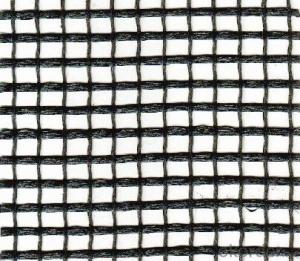

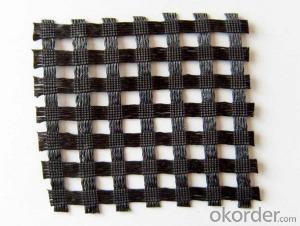

composite geogrid is made by blending high tensile steel wire which is specially processed and polyethylene (P.E.), and adds other accessory ingredients and though squeezing out to make it become complex belt that gas good tension resistance, and the surface ha rough embossing, which makes the reinforced geosynthetics belt. Based on the single belt and arranged by knitting or clamping vertically and horizontally according to certain space and fused on their connection points by using specially reinforced fusion-jointing technique, which makes the reinforced geogrid.

Performance

High intensity and small distortion

Slow creep

Anti-corrosive, long-term service life, steel plastic geogrid material with steel plastic material as its protector, and with various accessory ingredients to make the product have the abilities if anti-aging and anti-oxidation resisting permant project more than 100 years, and the performance is superior, the size stability is good.

The construction is convenient, the cycle is short, the cost is low; it is easy to lay down, join, locate, avoids overlapping cross over, but reduces the project cycle effectively, saves the building cost of projects by 10%--50%.

Application

The products are applied widely in railway, bridge, dock, retaining wall, dam ti reinforce the soft soil’s foundation and to resist the road surface’s crack.

Specifications

The high-strength One-way (vertical) Geogrid

Item | GSZ30 | GSZ50 | GSZ80 | GSZ100 | GSZ120 | GSZ150 |

Vertical limit-tensile strength KN/m ≥ | 30 | 50 | 80 | 100 | 120 | 150 |

Vertical limit elongation(%)≤ | 3 | |||||

The tensile strength of elongation at 1%KN/m ≥ | 23 | 38 | 63 | 81 | 98 | 125 |

The high-strength steel-plastic Two-way (vertical and horizontally) Geogrid

Item | GSZ30-30 | GSZ45-45 | GSZ60-60 | GSZ80-80 | GSZ100-100 | GSZ120-120 |

Biaxial ultimate tension KN/m ≥ | 30 | 45 | 60 | 80 | 100 | 120 |

Biaxial ultimate elongation (%)≤ | 3 | |||||

The tensile strength of elongationat 1% KN/m ≥ | 23 | 36 | 48 | 63 | 81 | 98 |

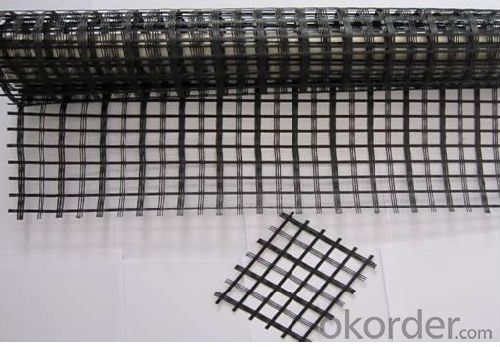

Packaging and storage

The Steel plastic composite geogrid, the length of the product roll is decided by the construction requests. The rolls are to be horizontally placed and not more than 6 layers high.

Unless otherwise specified, the production should be stored in a non-corrosive gas, non-dust, well-ventilated, dry and rainproof area.

It is recommended that the room temperature should be maintained below 35°C,and humidity should be always maintained below 65%

- Q: Can geogrids be used in temporary retaining structures?

- Yes, geogrids can be used in temporary retaining structures. Geogrids are commonly used in construction projects to reinforce soil and provide stability to retaining walls and structures. They are designed to withstand high tensile forces and can be easily installed and removed, making them suitable for temporary applications.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically involve preparing the subgrade, ensuring proper anchoring and overlap of the geogrid, and compacting the fill material. Additionally, the specifications may include guidelines for the required geogrid strength, aperture size, and roll width, as well as the recommended installation techniques and equipment. It is essential to follow the manufacturer's instructions and any relevant industry standards for a successful geogrid installation.

- Q: Can geogrids be used in reinforcement of mechanically stabilized slopes?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized slopes. Geogrids are often used to improve the stability and strength of slopes by providing additional reinforcement to the soil. They help to distribute the loads and reduce lateral movement, thus preventing slope failure. Additionally, geogrids can enhance the overall performance and longevity of mechanically stabilized slopes by improving their resistance to erosion and environmental factors.

- Q: Can geogrids be used in erosion control blankets?

- Yes, geogrids can be used in erosion control blankets. Geogrids are commonly used as reinforcement materials in erosion control applications to provide additional strength and stability to the blanket, preventing soil erosion and promoting vegetative growth.

- Q: Can geogrids be used in reinforced earth bridge piers?

- Yes, geogrids can be used in reinforced earth bridge piers. Geogrids are commonly used as a reinforcement material in soil structures, including bridge piers, to enhance stability and provide additional strength. They are effective in distributing loads, reducing settlement, and improving overall performance of the structure.

- Q: Can geogrids be used in reinforcement of embankments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of embankments on collapsible soils. Geogrids are a type of geosynthetic material that can provide structural stability and improve the overall strength of embankments. They are commonly used to distribute loads, reduce lateral spreading, and prevent soil erosion. When used in conjunction with proper engineering techniques, geogrids can effectively reinforce embankments on collapsible soils and mitigate potential issues related to soil collapse.

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are typically resistant to acid degradation.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing tensile strength and stabilizing the soil, preventing its movement and potential failure. The geogrids act as reinforcements that distribute the applied loads more evenly, reducing the stresses on the soil and improving its overall stability. Additionally, geogrids enhance the bearing capacity of the structure, increase its resistance to settlement, and minimize the potential for deformation or displacement.

- Q: What is the meaning of 400g geotextiles /100g woven fabric

- Should be a layer of woven cloth PE film and a layer of geotextile. PE membrane and geotextile 400g

- Q: What is the minimum net size of geogrid mesh center?

- WhaThis depends on the material, the grid size of different materials is different, fiberglass and polyester because it is prepared, so the smallest mesh size, plastic medium, the largest steel and PP welding.t is the minimum net size of geogrid mesh center?

Send your message to us

Geocells for Driveways - Fiberglass Geogrid with Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords