Geocells and Geogrids - Biaxial Polyester Geogrid Prices Geo Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

1.polyester geogrid

2.manufacturer/good

3.ISO9001:2008

4.high tensile modulus and tensile strength

5.warp-knitting geogrid

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

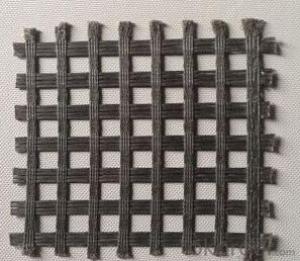

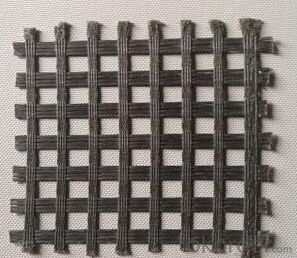

Geogrid Show:

FAQ

1 | How about the delivery time? |

Lead time since receipt of 30% T/T deposit payment: 3 weeks. | |

2 | What kind of payments does jenor support? |

T/T | |

3 | What's are the MOQ? |

We can according to your condition to set the MOQ. And we can provide you samples for quality inspection. | |

4 | How to deal with the sample charge? |

Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee If you set the order . | |

5 | Can you produce the product according to customers' requirements ? |

Sure, we are professional manufacturer, OEM and ODM are both welcome. | |

6 | Can you tell me your main customers? |

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here. |

- Q: What are the typical applications of geogrids in geotechnical engineering?

- Geogrids are commonly used in geotechnical engineering for various applications such as soil reinforcement, slope stabilization, retaining wall construction, and pavement reinforcement.

- Q: Are geogrids suitable for reinforcing embankments?

- Yes, geogrids are suitable for reinforcing embankments. Geogrids are made of strong materials such as polyester or polypropylene and are designed to provide stability and strength to soil structures. They can be used to reinforce embankments by distributing load more evenly, reducing soil movement, and improving overall stability. Geogrids also help prevent erosion and increase the overall lifespan of embankments.

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are flexible and durable materials that can reinforce soil and improve its stability. In seismic zones, where the ground is prone to shaking and instability during earthquakes, geogrids can effectively enhance soil resistance to lateral movement, reduce soil liquefaction, and provide greater overall stability to structures. Their ability to distribute loads and increase soil confinement makes them highly suitable for use in seismic zones.

- Q: Geogrid standard geogrid price geogrid role

- plastic geogridThe plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length. As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%. If the carbon black and other anti-aging materials are added in the geogrid, the utility model has the advantages of good acid resistance, alkali resistance, corrosion resistance, aging resistance and the like. The bidirectional geogrid two-way geogrid is made of high molecular polymer through extrusion, plate forming, punching process and then longitudinal and transverse stretching. The material has great tensile strength in both longitudinal and transverse directions, the chain system of this structure in the soil can also provide a more effective force to bear and spread of the ideal, to adapt to the foundation of unidirectional geogrids uniaxial geogrid in the large area of a permanent load is a polymer by extrusion pressure a thin plate and punching network rules, and then the longitudinal stretch. This process make the linear polymer into a state of orientation and form long oval mesh structure integrity and uniform distribution of nodes with high intensity. The structure has very high tensile strength and tensile modulus,.

- Q: Are geogrids suitable for use in green roof systems?

- Yes, geogrids are suitable for use in green roof systems. Geogrids provide stability and reinforcement to the roof system, preventing soil erosion and promoting the growth of vegetation. They also help distribute the weight evenly, making the green roof more structurally sound.

- Q: Are geogrids suitable for use in high groundwater conditions?

- Yes, geogrids are suitable for use in high groundwater conditions. Geogrids are commonly used in civil engineering applications, including in areas with high groundwater levels. They are designed to provide soil stabilization and reinforcement, even in challenging conditions such as high water tables. Geogrids have excellent drainage properties and are resistant to water, making them a reliable solution for projects in high groundwater conditions.

- Q: Are geogrids suitable for reinforcing steep slopes?

- Yes, geogrids are suitable for reinforcing steep slopes. Geogrids are high-strength, flexible, and durable materials that can provide stability and prevent soil erosion on steep slopes. They enhance the soil's shear strength, distribute loads, and improve slope stability, making them an effective solution for reinforcing steep slopes.

- Q: What is the effect of junction strength on geogrid performance?

- The junction strength of a geogrid has a significant impact on its overall performance. A higher junction strength enhances the geogrid's ability to distribute loads and resist deformation, leading to improved soil reinforcement and stability. It helps to prevent the geogrid from tearing or failing under high stress conditions, thereby increasing its durability and lifespan. Additionally, a stronger junction also enhances the geogrid's interlocking mechanism, allowing for better load transfer and confinement of soil particles. Overall, a higher junction strength positively influences the performance and effectiveness of geogrids in various geotechnical applications.

- Q: Who has the "highway geosynthetics geogrid" specification

- JT/T925.1 2017 highway engineering geosynthetics

- Q: What is the effect of creep on geogrid performance?

- Creep can have a significant impact on the performance of geogrids. Over time, the constant stress and strain on the geogrid can cause it to slowly deform and lose its original shape and strength. This can result in reduced load-bearing capacity and overall effectiveness of the geogrid in reinforcing and stabilizing the soil. It is important to consider creep behavior when designing and selecting geogrids for long-term applications to ensure their durability and performance.

Send your message to us

Geocells and Geogrids - Biaxial Polyester Geogrid Prices Geo Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords