Self Adhesive Fiberglass Geogrid Geocells Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Manufacturer with Self Adhesive

Description Of Fiberglass Geogrid Manufacturer with Self Adhesive:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle. This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Manufacturer with Self Adhesive:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer with Self Adhesive:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer with Self Adhesive:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

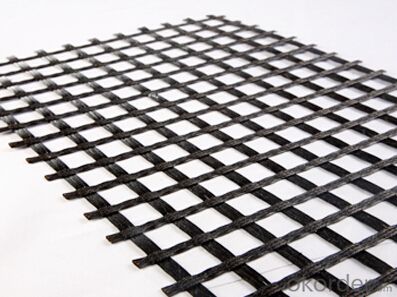

IMages of Fiberglass Geogrid Manufacturer with Self Adhesive:

FAQ of Fiberglass Geogrid Manufacturer with Self Adhesive:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids prevent soil erosion?

- Geogrids prevent soil erosion by providing reinforcement and stability to the soil. These synthetic materials are installed within the soil to form a strong, interconnected network that improves the soil's shear strength. This reinforcement prevents the soil particles from being washed away by water or blown away by wind, effectively reducing erosion.

- Q: PA66 plus 30% glass Shrink is how much

- The main function of engineering plastics used in automobile is to make the automobile lightweight, so as to achieve the purpose of fuel saving and high speed. Developed countries will be used as an indicator of the amount of automotive plastics as a measure of the level of design and manufacture of automobiles, the world's largest automotive single plastic consumption is Germany, plastic consumption accounted for 15% of the overall material. In recent years, China's rapid development of automobile industry, the automobile annual output of more than 4 million vehicles, according to the prediction of foreign plastic content, the automotive industry using modified plastics in more than 500 thousand tons, of which the engineering plastics accounts for a large proportion of the five engineering plastics, performance characteristics of different purposes, in the car also there is emphasis on.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in high rainfall areas?

- Geogrids improve the performance of mechanically stabilized slopes in high rainfall areas by providing reinforcement and enhancing the stability of the soil structure. They act as a barrier against soil erosion and prevent slope failures by distributing the load more evenly. Additionally, geogrids increase the bearing capacity of the soil, reduce settlement, and improve overall slope stability, making them highly effective in managing the increased water flow and potential slope movement in high rainfall areas.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, load requirements, and installation method. Generally, square or rectangular aperture shapes are preferred for applications involving stabilization and reinforcement of soils, while triangular or diamond-shaped apertures are more suitable for applications requiring high tensile strength and flexibility. It is crucial to consult geosynthetic experts or manufacturers to determine the most appropriate geogrid aperture shape for a specific project.

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- The staggered distance of the lap joint shall not be less than 300 mm. Specific specification (geotextile lap laying)

- Q: What kind of experiments need to be done to check geogrid

- Generally do tensile test, the main determination of 2%, 5% and 10% corresponding strength. Strict requirements for the deformation of the project, strictly speaking, but also to do creep test, but the creep experiment takes too long, most projects do not do.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones?

- Geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones by enhancing the stability and resistance to seismic forces. The geogrids act as a reinforcement material, increasing the tensile strength and preventing soil movement during seismic events. They help distribute the seismic forces more evenly, reducing the potential for slope failure and improving overall slope stability.

- Q: Can geogrids be used in reinforcement of coastal structures?

- Yes, geogrids can be used in the reinforcement of coastal structures. Geogrids are commonly used in coastal engineering to enhance the stability and strength of structures such as seawalls, revetments, and breakwaters. They provide additional reinforcement by improving soil cohesion and preventing erosion, thus increasing the durability and resilience of coastal structures against wave action and other environmental forces.

- Q: What is the overlap length of the two-way geogrid? What is the overlap length of geotextiles?

- It should be 20cm to 40cm, it's a little longer

- Q: Glass fiber mesh cloth is mainly used in what place

- Reinforced cement products (such as Rome column, flue, etc.) Danyang BOSCH Molding Co., Ltd.. 3) granite, mosaic dedicated network, marble back affixed to the network

Send your message to us

Self Adhesive Fiberglass Geogrid Geocells Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords