Self-Adhesive Aluminum Foil Sheets with Smooth Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

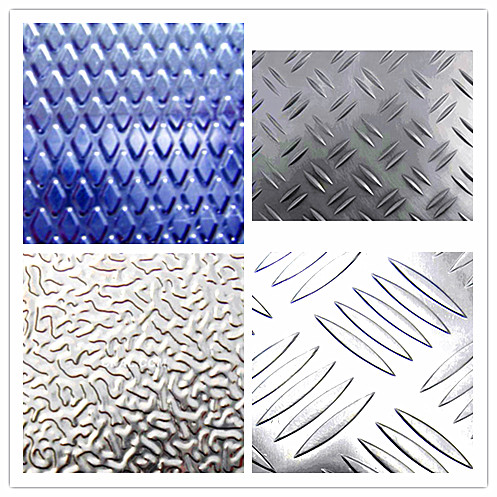

Aluminum Checkered Plate for Five-Bar :

two bar five bar Aluminum Checkered Sheet Plate

1.Alloy: 1100 1200 1050 2024 2014 2017 3003 5052 6061 6063 etc.

2. Temper: O, F, H111, H112, H12 ,H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, T3, T4 , T6, T7, T351 , T451, T651, T851.

3. Dimensions can be produced according to clients specifications.

4.Good plasticity, conductivity.

5. Generally used in industry and architecture industries.

Packing,

Covering with standard and package or according to your demand.

Machinability :

This alloy has relatively fair machinability. It is easier to machine in the hard temper than as annealed and the quality of finish is better if machined in the hard condition. Oil lubricants should be used for machining, except that very light cuts may .

Forming :

AL 5052 is readily formed at room temperature. Successive cold working decreases the formability.

Corrosion Resistance :

Corrosion resistance to salt water and general atmospheric conditions is good.

Heat Treatment:

AL 5052 cannot be hardened by means of heat treatment. It does harden due to cold working.

- Q: Are aluminum sheets suitable for wastewater treatment applications?

- Yes, aluminum sheets are suitable for wastewater treatment applications. Aluminum is a versatile material that offers several benefits for use in wastewater treatment processes. Firstly, aluminum sheets are highly resistant to corrosion, which is essential in the harsh and corrosive environment of wastewater treatment plants. This resistance ensures that the aluminum sheets will not deteriorate or react with the chemicals present in the wastewater, thereby maintaining their structural integrity. Additionally, aluminum sheets have excellent thermal conductivity properties, allowing for efficient heat transfer in processes like wastewater disinfection. This thermal conductivity aids in the effective removal of harmful bacteria and contaminants from the wastewater, enhancing the overall treatment process. Furthermore, aluminum sheets are lightweight yet durable, making them easy to handle and install in wastewater treatment systems. This characteristic also contributes to their cost-effectiveness, as they require less maintenance and are less prone to damage compared to other materials. Moreover, aluminum is a sustainable material and can be recycled, reducing the environmental impact of wastewater treatment applications. Recycling aluminum sheets can help conserve natural resources and reduce energy consumption, making it an environmentally friendly choice. In conclusion, aluminum sheets offer numerous advantages for wastewater treatment applications. Their corrosion resistance, thermal conductivity, lightweight nature, and recyclability make them a suitable and efficient material for use in wastewater treatment processes.

- Q: Can aluminum sheets be brushed or satin finished?

- Aluminum sheets have the capability to undergo brushing or satin finishing. Brushing or satin finishing is a method that involves the creation of a textured surface on the aluminum sheets. This can be accomplished by utilizing abrasive materials like sandpaper or wire brushes to generate a pattern of fine lines or scratches on the metal's surface. The purpose of this process is often to enhance the appearance of the aluminum sheets by providing them with a more matte and textured finish. Moreover, brushing or satin finishing can also serve to conceal minor imperfections or scratches on the surface of the aluminum sheets. In summary, the option to brush or satin finish aluminum sheets allows for flexibility in achieving desired aesthetics and surface textures in various applications.

- Q: what's the size of aluminum sheet circle?

- Aluminum sheet circle’s size is usually the width of coil stock (mm) : 500-1250,800-1400,1000-1600, thickness of coil stock (mm) : 0.4-3.0,1.0-6.0, weight of coil stock (kg) : 8000,10000, diameter of blank(mm) : 85-660,85-750,100-900. Aluminum sheet circle is broadly used in electron, daily chemical industry, medicine, education and car accessories industry. Electrical appliance, thermal insulation, machine manufacturing, cars, spaceflight, military industry, mould, construction, printing and other industries. Kitchenware, such as non-stick pan, pressure cooker, etc. and hardware, such as lampshade, shell of water heater, etc. they are one of the highly processed aluminum products with largest consumption.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior walls. They are lightweight, durable, and resistant to weathering and corrosion, making them suitable for facades. Aluminum sheets can be easily shaped and offer design flexibility. They also have good thermal properties and can be coated or finished in various ways to enhance their appearance and performance. However, they may not provide the same insulation as traditional materials, so additional insulation may be required.</p>

- Q: Are 101 aluminum sheets suitable for architectural louvers or sunscreens?

- Yes, 101 aluminum sheets are suitable for architectural louvers or sunscreens. They possess excellent strength, durability, and corrosion resistance, making them ideal for outdoor applications. Additionally, their lightweight nature allows for easy installation and maintenance.

- Q: What is the use?

- A series of 1000, representing the 1050106010701000 series aluminum is called pure aluminum, all in series 1000 series aluminum content belongs to one of the largest series. The purity can reach more than 99%. Because the technology does not contain other elements, the production process is relatively simple, the price is relatively cheap, is most commonly used in the conventional industry a a series of circulation on the market for most of the 1050 and 1060 series.1000 series aluminum plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach to the top 99.5% qualified products. Aluminum Alloy technical standards China (gB/T3880-2006) is also clear that the aluminum content of 1050 aluminum content reached 99.5%. the same 1060 series aluminum must reach above 99.6%.The two and 2000 series aluminum 2A16 (LY16) 2A06 (LY6) features of 2000 series aluminum is high hardness, which belongs to the copper content is the highest, probably around 3-5%.2000 series aluminum plate belongs to aviation aluminum, currently in the conventional industries should not be used. Our current production of 2000 series aluminum manufacturers quality can not less. Compared with foreign countries. Currently imported aluminum is mainly provided by the production enterprises of South Korea and Germany. With the rapid development of China's aerospace industry, aluminum production technology of the 2000 series will be further improved.

- Q: What are the different types of alloys used for aluminum sheets?

- There are various types of alloys used for aluminum sheets, including 1xxx, 3xxx, 5xxx, and 6xxx series. Each alloy has unique properties and characteristics, making them suitable for different applications. The 1xxx series alloys are pure aluminum, while the 3xxx series alloys contain manganese and exhibit good formability. The 5xxx series alloys have magnesium as the primary alloying element and offer excellent corrosion resistance. Lastly, the 6xxx series alloys are known for their combination of strength, formability, and weldability, with magnesium and silicon as their main alloying elements.

- Q: Can aluminum sheets be powder coated?

- Indeed, it is possible to powder coat aluminum sheets. Powder coating, a widely utilized technique for achieving a sturdy and appealing finish, entails the application of dry powder to surfaces, specifically aluminum, followed by heat treatment. Aluminum is a favored choice for powder coating, owing to its lightweight, corrosion-resistant, and adaptable properties. Through the powder coating process, aluminum sheets acquire a flawless, uniform, and enduring surface. Moreover, this method offers an extensive array of color choices and finds extensive utility in architectural, automotive, and industrial settings.

- Q: Can aluminum sheets be used for structural purposes?

- Yes, aluminum sheets can be used for structural purposes. Aluminum is a lightweight and durable material with high tensile strength, making it suitable for various construction applications, including structural components such as beams, columns, and panels. Its corrosion resistance and ability to withstand extreme temperatures further enhance its suitability for structural use.

- Q: How does the formability of aluminum sheet vary with different alloys?

- The formability of aluminum sheet can vary significantly with different alloys due to variations in their chemical composition and mechanical properties. Aluminum alloys are typically alloyed with other elements such as copper, manganese, magnesium, and zinc to enhance specific characteristics such as strength, corrosion resistance, and formability. Some aluminum alloys, such as the 1xxx series (pure aluminum) and the 3xxx series (alloyed with manganese), have excellent formability and are often used for deep drawing applications. These alloys can be easily formed into complex shapes without cracking or tearing. On the other hand, alloys with higher strength properties, such as the 2xxx series (alloyed with copper) and the 7xxx series (alloyed with zinc), typically have reduced formability. These alloys are often used in structural applications where strength is crucial, but they may require more careful handling and processing to avoid cracks or other defects during forming. Alloys in the 5xxx series (alloyed with magnesium) generally offer a good balance of formability and strength. They are widely used in various industries, including automotive and aerospace, for their ability to be easily formed into different shapes while providing adequate strength and corrosion resistance. It is important to note that the formability of aluminum sheet is not solely determined by the alloy composition but also influenced by other factors such as the thickness of the sheet, the temperature during forming, and the specific forming process employed (e.g., deep drawing, bending, stretching). These factors can interact with the alloy properties to affect the formability characteristics of aluminum sheet. Therefore, it is essential to carefully select the appropriate alloy and process parameters to achieve the desired formability for specific applications.

Send your message to us

Self-Adhesive Aluminum Foil Sheets with Smooth Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords