Schedule 40 Seamless Carbon Steel Pipe ST52 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

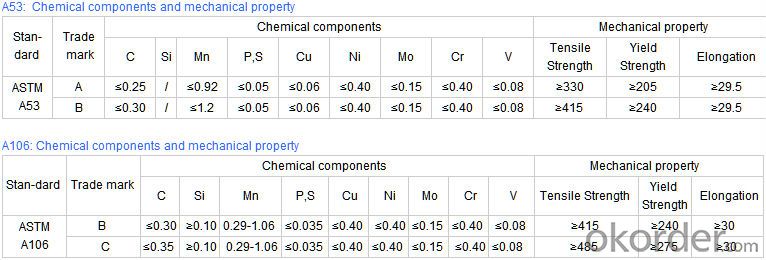

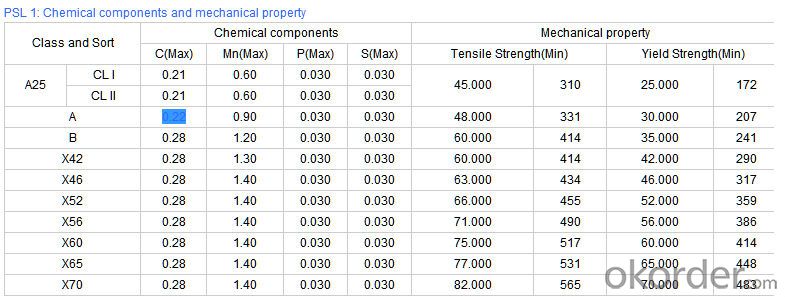

Technical Parameters of Seamless Steel Pipe

- Q: How are steel pipes insulated to prevent noise transmission?

- Steel pipes are typically insulated using specialized materials that are specifically designed to reduce noise transmission. These insulation materials, such as foam or mineral wool, are wrapped around the steel pipes to create a barrier that absorbs sound waves and prevents them from traveling through the pipes. Additionally, the insulation is often covered with a protective layer, such as aluminum or PVC, to further enhance the soundproofing properties and provide mechanical protection to the insulation.

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Yes, steel pipes can be used for conveying sewage and wastewater. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for transporting various types of fluids, including sewage and wastewater. Additionally, steel pipes can withstand high pressure and are capable of handling the abrasive and corrosive nature of sewage and wastewater, making them a reliable choice for such applications.

- Q: How long is the seamless tube?

- Welded pipe is generally 6912 meters fixed length, seamless pipe on the market in general non fixed foot, but usually more than 6 meters

- Q: What are the different types of couplings used with steel pipes?

- There are several types of couplings that can be used with steel pipes, including threaded couplings, compression couplings, and flanged couplings. Threaded couplings have threads on the inside and outside that allow pipes to be screwed together. Compression couplings use a compression fitting to connect pipes, providing a tight and secure connection. Flanged couplings have flanges on each end that are bolted together, creating a strong and durable joint.

- Q: How are steel pipes used in the construction of oil storage tanks?

- Steel pipes are commonly used in the construction of oil storage tanks for several purposes. Firstly, they are used to create the framework and structure of the tank, providing strength and durability to support the weight of the stored oil. Additionally, steel pipes are used for the internal and external piping systems of the tank, facilitating the transportation of oil to and from the tank. Finally, steel pipes are also employed for the ventilation and drainage systems of the tank, ensuring proper airflow and drainage to prevent any potential hazards or damage.

- Q: What is the difference between steel pipe and concrete pipe?

- The main difference between steel pipe and concrete pipe lies in their material composition. Steel pipes are made from steel, which provides strength, durability, and resistance to corrosion. On the other hand, concrete pipes are made from a mixture of cement, aggregates, and reinforcing materials, offering advantages such as fire resistance and the ability to withstand high pressure. While steel pipes are commonly used for transporting fluids and gases, concrete pipes are often used in drainage and sewage systems.

- Q: Can steel pipes be used for water treatment plants?

- Yes, steel pipes can be and are commonly used in water treatment plants. Steel pipes have several advantages such as high strength, durability, and resistance to corrosion, making them suitable for conveying and transporting water in water treatment processes.

- Q: How are steel pipes protected against fire?

- Steel pipes are typically protected against fire through the application of fire-resistant coatings or by encasing them in fire-rated materials, such as concrete or gypsum board. Additionally, fire sprinkler systems or fire-resistant insulation may be installed around the pipes to provide an added layer of protection.

- Q: Can steel pipes be bent or shaped to meet specific requirements?

- Yes, steel pipes can be bent or shaped to meet specific requirements through various techniques such as hot bending, cold bending, or using specialized machinery like pipe benders.

- Q: What are the different types of supports used for underground steel pipes?

- There are several types of supports commonly used for underground steel pipes, including concrete cradles, saddle supports, and thrust blocks. These supports help distribute the weight and forces acting on the pipe, ensuring its stability and preventing damage.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe ST52 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords