Schedule 40 Seamless Carbon Steel Pipe 13CrMo45 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

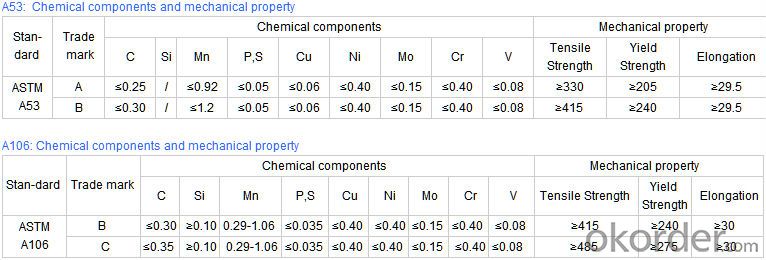

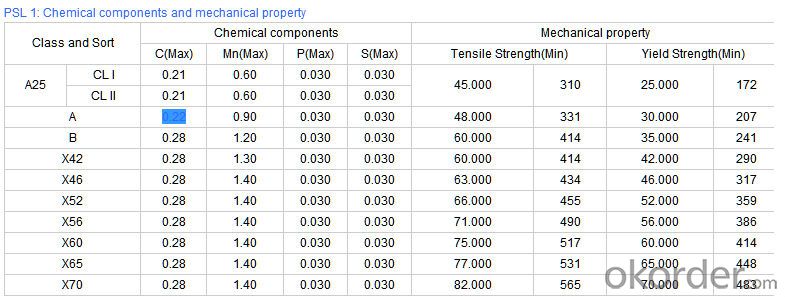

Technical Parameters of Seamless Steel Pipe

- Q: Can steel pipes be threaded?

- Yes, steel pipes can be threaded.

- Q: How does the price of steel pipes vary based on size and grade?

- The price of steel pipes varies based on their size and grade. Generally, larger pipes tend to have higher prices due to the increased amount of materials and manufacturing processes involved. Additionally, the grade of steel used in the pipes also affects the price, with higher-grade steel pipes being more expensive. This is because higher-grade steel offers better strength, durability, and corrosion resistance, making it suitable for specialized applications. Therefore, the price of steel pipes increases as both the size and grade increase.

- Q: 304 stainless steel tube with the diameter of 25*2-3 is what mean

- This is according to the "water drawing standards" (GBT50106-2001) in 2.4.2-2 seamless steel pipe, welded steel pipe (straight or spiral seam), brass, stainless steel pipe, pipe diameter should be D diameter * thickness representation (such as D108 * 4 and D159 * 4.5); and the provisions of the habit of acting D with seamless pipe diameter.

- Q: How do steel pipes handle soil movement?

- Steel pipes are highly resistant to soil movement due to their strength and durability. The rigid nature of steel pipes allows them to withstand ground shifting and settling without deforming or breaking. Additionally, steel pipes are often installed with proper anchoring and support systems to further enhance their ability to handle soil movement.

- Q: Can steel pipes be used for transporting gases?

- Yes, steel pipes can be used for transporting gases. Steel pipes are commonly used for gas transportation due to their high strength, durability, and resistance to corrosion. They can effectively withstand high pressure and temperature conditions, making them a reliable choice for gas transmission systems.

- Q: Can steel pipes be used for conveying corrosive substances?

- Steel pipes can be used for conveying corrosive substances, but it is important to choose the right type of steel and consider additional protective measures. Stainless steel pipes, for example, are highly resistant to corrosion and can handle a wide range of corrosive substances. However, it is crucial to consider the specific corrosive properties of the substance being conveyed and the concentration levels. In some cases, additional protective coatings or linings may be necessary to prevent corrosion and ensure the longevity of the steel pipes. Regular maintenance and inspection are also essential to detect and address any signs of corrosion to prevent leaks or failures in the piping system. Overall, steel pipes can be used for conveying corrosive substances, but proper material selection, protective measures, and maintenance are vital to ensure safe and efficient operations.

- Q: How can galvanized steel pipe be connected with stainless steel pipe?

- The method of non direct fusion is adopted, such as blue, silk head and movable joint

- Q: How are steel pipes used in the construction of underground utilities?

- Steel pipes are commonly used in the construction of underground utilities as they are highly durable and can withstand the pressure and weight of the surrounding soil. They are primarily used for various applications such as transporting water, natural gas, and sewage, as well as for electrical conduit systems. Additionally, steel pipes are resistant to corrosion, which makes them ideal for long-term underground installations.

- Q: How do steel pipes perform in marine environments?

- Steel pipes perform well in marine environments due to their high corrosion resistance. They are typically coated with protective layers such as zinc or epoxy, which further enhance their ability to withstand the harsh conditions of saltwater, waves, and constant exposure to moisture. These pipes are capable of withstanding the corrosive effects of seawater, making them reliable for various applications like offshore oil rigs, shipbuilding, and coastal infrastructure.

- Q: How are steel pipes used in the manufacturing of ships?

- Steel pipes are used in the manufacturing of ships for various purposes, such as carrying fluids and gases, providing structural support, and facilitating efficient operation of the ship's systems. They are used for plumbing, ventilation, and firefighting systems, as well as for the construction of hulls and other vital components. Overall, steel pipes play a crucial role in ensuring the functionality and safety of ships during their construction and operation.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 13CrMo45 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords