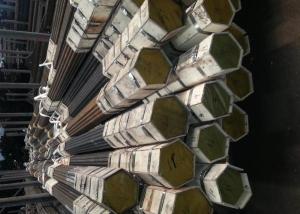

JIS G3455(Carbon Steel Pipes For High Pressure Service)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS G3455(Carbon Steel Pipes For High Pressure Service)

Standard: JIS G3455 Grade: STS 38, STS 42, STS 49. OD: 10.5-660.4 mm. Thickness: 1.7-64.2mm Length:39.34'/12M.max... JIS G3444,ASTM A53/ASTM A36 BS1387/BS1139/EN39/EN10219/EN10217/EN10297/EN10296/EN10025 DIN EN10216,DIN EN10208,DIN EN10217, DIN28180,DIN17175, DIN EN10305, DINEN 10025 Q195/215/235/345,SS330/SS400/SS500,S235JR/S235J0/S235J2,STK290,STK400,STK490,STK500,STK540 | |||

O.D | O.D tolerance | W.T | Thickness Tolerance |

48.3MM/11/2'' | ±0.5mm | 2.0-4.0MM | ±1% |

Length | 5.8-6.4M as per customers' requirements | ||

Certificate | ISO9001-2008,EN10210,API,Raw material cert,Mill cert,Reap on site inspection report,SGS,BV | ||

Standard | JIS G3444 ASTM A53/ASTM A36 BS1387/BS1139/EN39/EN10219/EN10217/EN10297/EN10296/EN10025 DIN EN10216,DIN EN10208,DIN EN10217, DIN28180,DIN17175, DIN EN10305, DINEN 10025 | ||

Material | Q195/215/235/345, SS330/400/500, S235JR/S235J0/S235J2, STK290,STK400,STK490,STK500,STK540 | ||

Inspection : | With Hydraulic Testing, Eddy Current , Infrared Test | ||

Technique: | Welded:Cold drawn,Hot rolled,heat extrusion | ||

Main market: | USA,Middle east,North and South America, Europe, South and southeast Asia,Australia,Africa, | ||

Origin place | Hebei,China | ||

HS code: | 73063090 | ||

Productivity | 20000Ton/Month | ||

Processing | galvanzied,Bared,painting,embossing,oiled,greeve,print etc | ||

Remarks | 1)Payment term : T/T,L/C,DP 2)Trade Terms : FOB / CFR /CIF 3)Minimum quantity of order:15 MT 4)Delivery period :15 to 30 Days . | ||

Usage/Applications:

construction

Packaging & Delivery:

In bundles or according to customers' requirements

40-50 days delivery on china port upon receiving original LC or prepayment.

- Q: What is the difference between API 5L and ASTM A53 steel pipes?

- API 5L and ASTM A53 are widely utilized carbon steel pipe standards with similar purposes but notable distinctions. 1. In terms of scope, API 5L pertains to seamless and welded pipes for transporting oil, gas, water, and other fluids. It encompasses plain-end, threaded-end, and belled-end pipe types. Conversely, ASTM A53 is a standard specification for seamless and welded black and hot-dipped galvanized steel pipes utilized in mechanical and pressure applications. 2. The manufacturing processes differ, as API 5L pipes undergo hot-rolling, while ASTM A53 pipes undergo either hot-rolling or cold-drawing. This variance affects the chemical composition and mechanical properties of the pipes. 3. Generally, API 5L pipes have a higher carbon content compared to ASTM A53 pipes. This discrepancy arises from the intended use of API 5L pipes for conveying oil, gas, and water, necessitating greater strength and durability. On the other hand, ASTM A53 pipes cater to mechanical and pressure applications, where lower carbon content is deemed appropriate. 4. API 5L pipes exhibit higher minimum yield strength and tensile strength than ASTM A53 pipes. This outcome stems from the increased carbon content and more stringent manufacturing process employed for API 5L pipes. Conversely, ASTM A53 pipes possess lower yield and tensile strength requirements, rendering them more suitable for general-purpose applications. 5. API 5L pipes offer various coating options, including black varnish, 3PE, FBE, among others, depending on the specific application requirements. In contrast, ASTM A53 pipes are typically hot-dipped galvanized to enhance corrosion resistance. In conclusion, API 5L and ASTM A53 steel pipes differ in scope, manufacturing processes, chemical compositions, mechanical properties, and coating options. The appropriate choice of pipe hinges upon specific application requirements, such as the nature of the conveyed fluid, operating conditions, and desired strength and durability.

- Q: What is the dimensional stability of steel pipes?

- The dimensional stability of steel pipes refers to their ability to retain their shape and dimensions under various conditions and external forces. Steel pipes are known for their excellent dimensional stability due to the inherent properties of the material. Steel is a strong and rigid material, which allows it to maintain its shape even under high pressure or changes in temperature. This makes steel pipes highly suitable for applications that require stability and resistance to deformation, such as in plumbing, oil and gas pipelines, and structural supports. In addition to its inherent strength, steel pipes also exhibit dimensional stability due to their manufacturing processes. Steel pipes are typically produced through methods like seamless or welded construction, which ensures their uniformity and consistent dimensions throughout the length of the pipe. This manufacturing precision contributes to the dimensional stability of steel pipes. Moreover, steel pipes are often treated with various protective coatings to enhance their resistance to environmental factors. These coatings, such as galvanization or epoxy coatings, not only protect against corrosion but also help maintain the dimensional stability of the pipes by providing an additional layer of strength and durability. Overall, the dimensional stability of steel pipes is one of the key reasons for their widespread use in different industries. Their ability to maintain their shape and dimensions, even under challenging conditions, ensures reliable and long-lasting performance in various applications.

- Q: How are steel pipes protected against external impact or mechanical damage?

- Various methods are employed to protect steel pipes from external impact or mechanical damage. One commonly utilized technique involves applying a protective coating onto the pipe's surface. This coating acts as a barrier, preventing direct contact between the pipe and external objects or forces. Coatings such as epoxy, polyethylene, or polyurethane are frequently chosen due to their excellent resistance to impact and abrasion. Another method of protection involves the use of pipe supports or clamps. These supports are positioned at regular intervals along the pipe's length, ensuring stability and minimizing excessive movement or vibration. They help distribute the load and absorb any external impacts, thus reducing the risk of mechanical damage. Additionally, steel pipes can be reinforced by wrapping them with materials like fiberglass, carbon fiber, or kevlar. These reinforcement materials provide an extra layer of strength and durability, enhancing the pipes' resistance to external impact and mechanical damage. Furthermore, burying the pipes underground or installing them within protective casings can offer an additional layer of protection. This measure shields the pipes from direct contact with external objects, reducing the potential for damage caused by accidental impacts or environmental factors. In conclusion, a combination of protective coatings, supports, reinforcements, and appropriate installation methods ensures that steel pipes are safeguarded against external impact or mechanical damage. This effectively extends their lifespan and maintains their structural integrity.

- Q: What are the different types of steel pipe fittings?

- There are various types of steel pipe fittings, including elbows, tees, reducers, couplings, unions, plugs, caps, and flanges.

- Q: How are steel pipes tested for quality control?

- Steel pipes are tested for quality control through various methods such as visual inspection, non-destructive testing, and physical testing. Visual inspection involves checking the pipes for any visible defects or inconsistencies in their appearance. Non-destructive testing methods like ultrasonic testing, magnetic particle testing, and radiographic testing are used to detect internal flaws or defects without damaging the pipes. Additionally, physical tests like tensile and impact testing are performed to evaluate the mechanical properties of the pipes. These comprehensive testing techniques ensure that steel pipes meet the required quality standards before they are used in various applications.

- Q: Can steel pipes be used for conveying abrasive materials?

- Yes, steel pipes can be used for conveying abrasive materials. Steel pipes are known for their durability and resistance to wear, making them suitable for handling abrasive materials. Additionally, steel pipes can be lined with various protective coatings or linings to further enhance their resistance to abrasion and extend their lifespan.

- Q: Is hot dipped plastic pipe steel?

- Hot dip plastic composite pipes used in coal mine gas drainage, ventilation system, fire water system, central air conditioning HVAC piping circulating water, industrial water supply and drainage, water supply and drainage life, conveying gas and other gases, power threading, chemical pipelines and water disposal pipe etc..

- Q: How are steel pipes used in sewage treatment plants?

- Steel pipes are commonly used in sewage treatment plants to transport wastewater, sludge, and other fluids throughout the facility. They provide a durable and corrosion-resistant solution for the harsh environments found in these plants. Steel pipes are used for various purposes, such as conveying raw sewage, distributing treated water, and carrying sludge for disposal or further processing.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are commonly used in telecommunications infrastructure for the installation of underground cables. These pipes provide protection and support to the cables, ensuring their longevity and efficient functioning. Additionally, steel pipes are used for the construction of telecommunication towers, providing a sturdy framework for antennas and other equipment.

- Q: How are steel pipes used in the construction industry?

- Steel pipes are commonly used in the construction industry for various purposes such as transporting fluids, structural support, and underground installations. They are utilized in plumbing systems, HVAC systems, and for conveying water, oil, and gas. Additionally, steel pipes are employed in the construction of high-rise buildings, bridges, and other infrastructure projects due to their durability, strength, and resistance to corrosion.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2005 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 390People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM not offered |

| Product Price Range | Average |

Send your message to us

JIS G3455(Carbon Steel Pipes For High Pressure Service)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords