Schedule 40 Seamless Carbon Steel Pipe 15CrMo CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

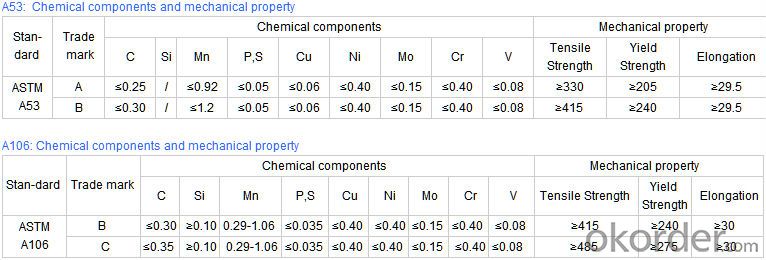

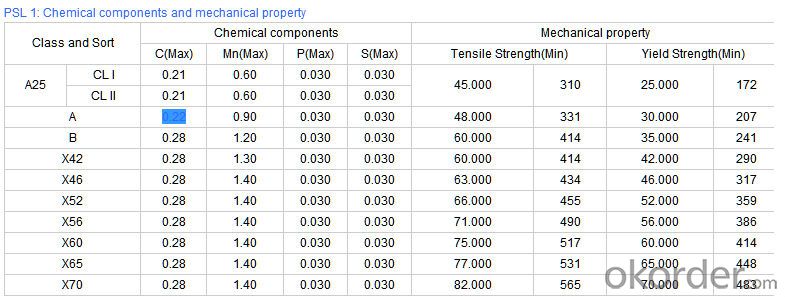

Technical Parameters of Seamless Steel Pipe

- Q: Can steel pipes be used for HVAC systems?

- Yes, steel pipes can be used for HVAC systems. Steel pipes are commonly used in HVAC systems for their durability, strength, and resistance to corrosion. They are particularly suitable for high-pressure applications and provide reliable and long-lasting performance in HVAC installations.

- Q: What are the different types of steel pipe connections for oil and gas pipelines?

- The different types of steel pipe connections for oil and gas pipelines include threaded connections, welded connections, and flanged connections. Threaded connections involve screwing the pipes together using a threaded end, which ensures a secure fit. Welded connections involve permanently joining the pipes together using welding techniques such as butt welding or socket welding. Flanged connections involve attaching flanges to the ends of the pipes and bolting them together, providing a strong and leak-proof connection.

- Q: What is the maximum allowable deflection for steel pipes?

- Industry standards and design codes typically determine the maximum allowable deflection for steel pipes. These regulations specify the acceptable limits of deflection to guarantee the pipes' structural integrity and functionality. The maximum allowable deflection can vary, depending on factors like pipe diameter, wall thickness, material properties, and the application type. To determine the specific maximum allowable deflection for a particular steel pipe application, it is crucial to reference relevant standards and codes such as the ASME B31.3 code for process piping or AWWA standards for water transmission and distribution pipes. Adhering to these guidelines ensures the safe and efficient operation of steel pipes in various industries and applications.

- Q: What is the difference between hot dip galvanized steel pipe and galvanized steel pipe?

- 1, the process is different, one is chemical treatment, one is physical treatment; hot-dip galvanized coating is reliable, not easy to fall off2, hot-dip galvanized coating thickness, so strong corrosion resistance. And zinc plating (electroplating) coating evenly, surface quality is better, coating thickness is generally between a few microns to more than ten microns.3 hot galvanizing is a chemical process, which belongs to electrochemical reaction. Zinc plating is a physical treatment, just brush a layer of zinc on the surface, there is no galvanizing inside, so the zinc layer is easy to fall off. Hot-dip galvanizing is used in building construction.4 、 hot galvanized pipe is to make molten metal and iron matrix reaction and produce alloy layer, so that the substrate and coating two combination.

- Q: How are steel pipes used in the pulp and paper industry?

- Steel pipes are commonly used in the pulp and paper industry for various applications such as transporting water, steam, chemicals, and other fluids throughout the production process. They are used in the construction of pipelines, conveying raw materials, and transferring finished products. Steel pipes provide durability, reliability, and resistance to corrosion, making them suitable for handling the harsh conditions and corrosive substances found in the industry.

- Q: Can steel pipes be used for electrical conduits?

- No, steel pipes cannot be used for electrical conduits. Electrical conduits need to be made of materials that are non-conductive and provide protection for the electrical wiring. Steel is a conductive material, so it poses a risk of electric shock and can cause interference with the electrical signals.

- Q: Can steel pipes be coated for aesthetic purposes?

- Indeed, steel pipes have the potential to be coated solely for aesthetic reasons. By applying coatings to steel pipes, not only can one achieve an attractive appearance, but also safeguard them against corrosion and other environmental influences. Numerous coating choices are at one's disposal when it comes to steel pipes, including powder coating, epoxy coating, and vinyl coating, among others. These coatings can be employed in various colors and textures to enrich the pipes' visual appeal and harmonize with their surroundings. Whether utilized in industrial settings, architectural endeavors, or for decorative purposes, the act of coating steel pipes has the power to metamorphose them into visually captivating components, all while preserving their structural integrity.

- Q: How do you protect steel pipes from external damage?

- There are several ways to ensure the protection of steel pipes from external damage: 1. Coating: To prevent external damage, it is advisable to apply a protective coating on the surface of the steel pipes. Different coating options such as epoxy, polyethylene, and fusion bonded epoxy (FBE) can be used. These coatings act as a barrier between the pipes and the surrounding environment, safeguarding them from corrosion, abrasion, and other external factors. 2. Cathodic Protection: Another method to protect the steel pipes from corrosion is by implementing cathodic protection. This involves connecting a less noble metal, either through sacrificial anodes or an impressed current, to the pipes. By doing so, the corrosive elements are attracted to the sacrificial metal, sacrificing it instead of the pipes. This process helps increase the pipes' lifespan and shields them from external damage. 3. Wrapping and Taping: To provide an additional layer of protection, it is recommended to wrap the steel pipes with materials like polyethylene or polypropylene tapes. These tapes act as a barrier against moisture, chemicals, and physical impact, ensuring the pipes are shielded from external damage. Additionally, heat shrink sleeves can be utilized to offer insulation and safeguard against corrosion. 4. Underground Installation: Proper installation techniques are crucial for safeguarding steel pipes from external damage. This includes ensuring appropriate trench depth, using suitable backfill materials, and avoiding excessive bending or stress during the installation process. Employing proper bedding and padding techniques also contributes to the pipes' protection against external factors. 5. Regular Inspection and Maintenance: It is essential to conduct periodic inspections and maintenance to detect any signs of external damage early on. This can involve visual inspections, non-destructive testing, or the utilization of advanced technologies such as pipeline integrity management systems. Timely repairs and maintenance help prevent further damage and extend the lifespan of the steel pipes. In conclusion, protecting steel pipes from external damage necessitates a combination of preventative measures, proper installation techniques, and regular maintenance. By implementing these strategies, the integrity of the pipes can be preserved, preventing corrosion, abrasion, impact, and other factors that could compromise their structural integrity.

- Q: What is the difference between steel pipe and concrete pipe?

- Steel pipe and concrete pipe are both commonly used for various applications, but they differ significantly in their material composition and properties. Firstly, the main difference lies in the materials used to manufacture these pipes. Steel pipes are made from steel, which is an alloy of iron and carbon. On the other hand, concrete pipes are made from a mixture of cement, aggregate (such as sand or gravel), and water. Secondly, steel pipes are known for their strength and durability. They can withstand high pressure, making them suitable for applications that require transporting fluids or gases under high pressure. Steel pipes also have a high resistance to corrosion, which is advantageous in environments where the pipe is exposed to moisture or chemicals. In contrast, concrete pipes are not as strong as steel pipes and are more prone to cracking or damage under high pressure. However, they are still capable of handling moderate pressure loads and are often used for drainage systems or sewage applications. Another significant difference is the installation process. Steel pipes are typically joined together using welding techniques, such as butt welding or socket welding. This creates a seamless and strong connection between the pipes. On the other hand, concrete pipes are often installed using rubber or gasketed joints, which are easier to assemble and disassemble. Cost is another factor where steel and concrete pipes differ. Steel pipes tend to be more expensive due to the higher cost of steel as a raw material and the additional labor required for welding and fabrication. Concrete pipes, on the other hand, are generally more cost-effective as the materials used in their production are more readily available and the installation process is simpler. In summary, the main differences between steel pipes and concrete pipes lie in their material composition, strength, resistance to corrosion, installation process, and cost. Steel pipes offer superior strength and durability, making them suitable for high-pressure applications and environments prone to corrosion. Concrete pipes, while not as strong, are cost-effective and commonly used for drainage systems or sewage applications.

- Q: What are the different testing methods used for steel pipes?

- To ensure the quality and reliability of steel pipes, various testing methods are employed. These methods include: 1. Non-destructive Testing (NDT): Ultrasonic testing, magnetic particle inspection, and liquid penetrant testing are utilized in NDT to identify surface or subsurface defects in steel pipes without causing any damage. 2. Mechanical Testing: Mechanical testing encompasses various tests to evaluate the mechanical properties of steel pipes, such as tensile strength, yield strength, elongation, hardness, and impact resistance. These tests determine the structural integrity and performance of the pipes. 3. Hydrostatic Testing: This method involves subjecting steel pipes to high-pressure water to assess their ability to withstand expected operating conditions. The pipes are filled with water and pressurized to a predetermined level for a specified duration. Any leaks or deformations are detected during this test. 4. Dimensional Inspection: This testing method ensures that steel pipes meet specified dimensional requirements. It involves measuring critical dimensions such as diameter, wall thickness, and length to verify compliance with applicable standards. 5. Visual Inspection: Trained inspectors visually assess the external appearance of steel pipes using this basic method. They examine the pipes for surface defects such as cracks, corrosion, or irregularities in shape or finish. 6. Chemical Analysis: Chemical analysis is conducted to determine the composition and elemental content of steel pipes. It ensures that the pipes are made from the correct grade of steel and meet required chemical composition standards. 7. Metallographic Examination: Metallography involves examining the microstructure of steel pipes under a microscope to evaluate their quality and integrity. It helps identify internal defects like grain boundaries, inclusions, or improper heat treatment that may impact overall performance. By employing these testing methods, manufacturers and inspectors can guarantee that steel pipes meet necessary quality standards and are suitable for their intended applications.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 15CrMo CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords