Scale Diamond Plate Aluminum Sheets - Low Price and Lightweight Oxidation Aluminum Alloy Gratings Stair Tread Steps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

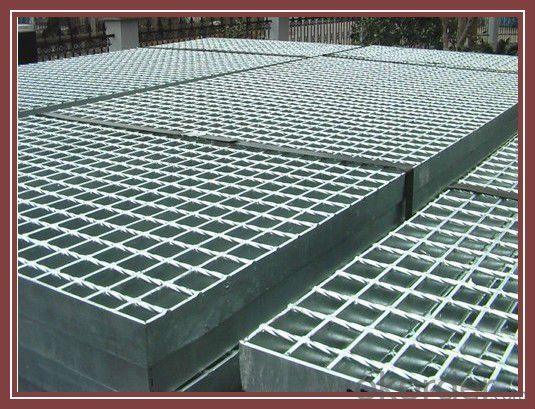

3.Drainage trench cover Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets suitable for aerospace engine components?

- Yes, aluminum sheets are suitable for aerospace engine components. Aluminum is a lightweight and durable material that offers excellent corrosion resistance and high strength-to-weight ratio, making it ideal for various aerospace applications. Additionally, aluminum's thermal conductivity properties are beneficial for engine components as they help dissipate heat effectively.

- Q: Can aluminum sheets be used for electrical wiring?

- No, aluminum sheets are not typically used for electrical wiring. Instead, copper wires are commonly used due to their superior electrical conductivity and lower resistance. Copper wires are more efficient and safer for transmitting electrical currents.

- Q: How does the surface cleanliness of aluminum sheet affect its adhesion properties?

- The surface cleanliness of aluminum sheet has a significant impact on its adhesion properties. A clean surface is crucial for achieving strong adhesion because any contaminants, such as dirt, oil, or oxidation, can inhibit the bonding process. These impurities create a barrier between the adhesive and the aluminum surface, reducing the strength of the bond. Therefore, ensuring the surface is properly cleaned and free from any contaminants is essential to maximize the adhesion properties of aluminum sheet.

- Q: Can aluminum be either conductive or magnitized?

- Aluminium saucepans and frypans demonstrate that Al conducts heat, aluminium wires are used because it is a very good conductor of electricity, but lighter and cheaper than copper, so used on overhead cables. Most lay-people would describe Al as non-magnetic. However, Al is weakly paramagnetic. It does not hold a magnetic field, but does respond to a (strong) magnetic field, albeit weakly. The effect is strongest at low temperatures, and decreases as temp increases.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, meaning it can be easily manipulated without breaking or cracking. This property makes it ideal for various applications where flexibility and customization are required. Aluminum sheets can be bent, folded, rolled, or formed using a variety of techniques such as press brakes, rollers, or specialized forming tools. This versatility allows for the creation of complex shapes and structures, making aluminum a popular choice in industries like construction, automotive, aerospace, and manufacturing.

- Q: How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ primarily in terms of thickness and applications. Aluminum sheets are typically thinner, ranging from 0.2mm to 6mm in thickness, whereas aluminum plates are thicker, usually starting from 6mm and going up to several inches thick. Aluminum sheets are commonly used for general purposes such as packaging, signage, and roofing due to their lightweight nature and flexibility. They are often bent, formed, and cut into various shapes and sizes to fulfill specific requirements. On the other hand, aluminum plates are typically used in applications that require higher strength and durability. With their greater thickness, they provide enhanced structural integrity and are commonly utilized in industries such as aerospace, automotive, and construction. Aluminum plates can withstand heavy loads and are often used as structural components in buildings, aircraft, and machinery. In summary, the main differences between aluminum sheets and aluminum plates lie in their thickness and the specific applications they are suited for. Sheets are thinner and more flexible, suitable for general purposes, while plates are thicker and stronger, ideal for heavy-duty applications that require structural integrity.

- Q: Can aluminum sheets be used for electrical busbars?

- Yes, aluminum sheets can be used for electrical busbars. Aluminum is a commonly used material for busbars due to its excellent electrical conductivity, lightweight nature, and cost-effectiveness. However, it is important to consider factors such as current carrying capacity, temperature rise, and mechanical strength when selecting aluminum sheets for busbar applications.

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability, making them ideal for various applications in industries such as construction, automotive, and aerospace.

- Q: What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets are equipped with exceptional electrical conductivity characteristics. With its low electrical resistance, aluminum finds extensive usage in diverse electrical applications. It boasts a high conductivity rating, marginally lower than that of copper, rendering it an effective electricity conductor. This attribute enables aluminum sheets to efficiently transmit electrical current with minimal energy wastage. Consequently, aluminum is extensively employed in power transmission lines, electrical wiring, and electrical connectors. Moreover, aluminum's conductivity renders it suitable for applications requiring heat dissipation, such as heat sinks in electronic devices. In general, aluminum sheets are renowned for their favorable electrical conductivity, making them a preferred choice in numerous electrical and electronic applications.

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is approximately 22.2 x 10^-6 per degree Celsius.

Send your message to us

Scale Diamond Plate Aluminum Sheets - Low Price and Lightweight Oxidation Aluminum Alloy Gratings Stair Tread Steps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords