Diamond Tread Aluminum Sheets for Sale - Low Price Aluminium Slab with Better Discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,7075,6063,8011, etc.

The temper is include H14, H22, F,O, H44,H112,F,O, H114,etc.

2. Main features of the product

a. the best-discount cheapest price

b. Frist-Class Service.

c. Shortest service.

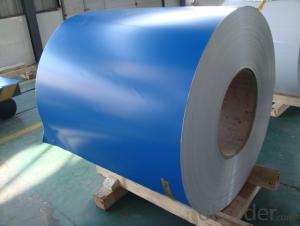

3. Image.

4. Product detailed sizes:

2000mm*2000mm,1000*1000MM, 1219mm*2438mm,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, big 5 bar, and small 5 bar and else grades,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the different finishes available for aluminum sheets?

- There are several different finishes available for aluminum sheets, each with its own unique characteristics and benefits. Some of the most common finishes include: 1. Mill finish: This is the most basic finish for aluminum sheets, characterized by a smooth, shiny surface. It is typically achieved by passing the aluminum through a rolling mill, leaving it with a natural appearance. Mill finish is often preferred for industrial applications where aesthetics are not a primary concern. 2. Anodized finish: Anodizing is an electrochemical process that adds a layer of oxide to the surface of the aluminum sheet, providing enhanced durability and corrosion resistance. Anodized finishes can range from clear to various colors, and they can also be dyed to achieve specific hues. 3. Brushed finish: This finish is achieved by brushing the aluminum sheet with abrasive materials, creating a pattern of fine lines on the surface. Brushed finishes offer a distinctive, textured appearance and are commonly used in architectural and decorative applications. 4. Polished finish: Polishing aluminum sheets involves buffing the surface to a high shine, resulting in a mirror-like, reflective finish. This finish is often chosen for decorative purposes, such as in interior design, automotive detailing, or jewelry making. 5. Embossed finish: Embossing involves creating raised patterns or designs on the surface of the aluminum sheet, adding texture and visual interest. It can be achieved through various methods, such as roll embossing or stamping, and is commonly used for decorative purposes or to improve grip on certain applications. 6. Powder-coated finish: Powder coating is a process where a dry powder is applied to the aluminum sheet and then cured under heat, creating a tough, durable, and attractive finish. Powder-coated finishes come in a wide range of colors and provide excellent resistance to fading, chipping, and scratching. These are just a few examples of the different finishes available for aluminum sheets. The choice of finish will depend on the specific requirements of the application, such as aesthetics, durability, and functionality.

- Q: Which is better, a water bottle made out of steel or one made out of aluminum?

- Aluminum

- Q: I am using Reeves Acrylic Colour Set and I plan on painting on Heavy Duty Ralphs Brand Aluminum Foil. Will the paint be able to go on the foil well? Tips? Thank you.

- i use aluminum foil to mix colors on and when it dries it DOES stick, however, it will scratch off really easy. just try experimenting. what do u need the foil for? maybe you can try the aluminum foil leaves? the flakes that you put ontop on the art instead of under it. that way you can glue it on and dont have to worry about it scratching off. foil looks beautiful on paintings :) how it turns out great

- Q: Are aluminum sheets suitable for electrical enclosures?

- Yes, aluminum sheets are suitable for electrical enclosures. Aluminum is a lightweight and durable material that offers excellent electrical conductivity and corrosion resistance, making it an ideal choice for protecting electrical components. Additionally, aluminum's thermal conductivity helps dissipate heat generated by the enclosed equipment, ensuring proper functioning and longevity.

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is approximately 0.000022 per degree Celsius. This means that for every degree Celsius increase in temperature, the aluminum sheet will expand by 0.000022 times its original length. This coefficient of expansion is important to consider in applications where the aluminum sheets may be exposed to varying temperatures, as it can affect the overall dimensions and stability of the material.

- Q: Aluminium magnesium alloy plate, 5052 aluminium plate, 5005 aluminium plate. 5252 aluminum plate performance and use

- Electronic cabinet material and LED LCD TV backlight board

- Q: And isn't aluminum extremely bad for ones health?

- Antiperspirant does two things. It kills sanitizes the area so it kills resident bacteria that eat the oils and secretions in the skin and produce odor. The aluminum compounds plug the pores and prevent sweat secretion. But be careful, aluminum has been implicated in Alzheimers disease.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- Is it pure Aluminum ? or an Alloy of some kind ? Are you heating the aluminum in a Steel Crucible ( bowl or spoon ) of which it will absorb much of the heat and it will be difficult to achieve the proper temp for the alum to melt. Is the Flame constant, No drafts to waver the flame off Target, In theory, the aluminum should melt if held long enough by itself over a large candle flame by tongs, also, How thick is the aluminum you are trying to melt? just trying to help, I'm no expert, but thought i'd give this a shot. Good Luck Color tells us about the temperature of a candle flame. The outer core of the candle flame is light blue -- 1670 K (1400 °C). That is the hottest part of the flame. The color inside the flame becomes yellow, orange and finally red. The further you reach to the center of the flame, the lower the temperature will be. The red portion is around 1070 K (800 °C).

- Q: How do you achieve a mirror-like finish on aluminum sheets?

- Achieving a mirror-like finish on aluminum sheets involves a series of steps to remove any imperfections and create a smooth, reflective surface. Here are the key processes involved: 1. Surface preparation: Start by thoroughly cleaning the aluminum sheet to remove any dirt, grease, or other contaminants using a mild detergent and water. Rinse and dry the surface completely. 2. Sanding: Use progressively finer grits of sandpaper or abrasive pads to remove any scratches, oxidation, or roughness on the aluminum surface. Begin with a coarser grit (around 120-180) and gradually move to finer grits (up to 1000 or higher) to achieve a smoother finish. Sanding should be done in a consistent direction to avoid creating visible scratches. 3. Polishing compounds: Apply a polishing compound or metal polish designed specifically for aluminum surfaces. Use a soft cloth or a buffing wheel to apply the polish and work it into the surface. Apply gentle pressure and move in circular motions to evenly distribute the polish. Repeat this step until the desired level of shine is achieved. 4. Buffing: Use a buffing wheel, preferably made of felt or cotton, to further enhance the shine. Apply a small amount of a high-quality polishing compound to the wheel and carefully buff the aluminum sheet in a consistent manner. Again, use circular motions and maintain a steady, even pressure. 5. Final polishing: To achieve a mirror-like finish, use a specialized aluminum polish or a metal finishing compound. Apply a small amount onto a clean cloth and gently rub the surface in circular motions. This final step helps remove any fine scratches or imperfections, adding a brilliant shine to the aluminum sheet. Remember to clean the aluminum sheet thoroughly after each step to remove any residue or excess polish. Additionally, always follow the manufacturer's instructions when using specific polishing compounds or tools, as they may have specific guidelines for optimal results. By following these steps carefully and patiently, you can achieve a mirror-like finish on aluminum sheets, transforming them into highly reflective surfaces that are both visually appealing and functional.

- Q: Can 101 aluminum sheets be anodized for outdoor architectural applications?

- Yes, 101 aluminum sheets can be anodized for outdoor architectural applications.

Send your message to us

Diamond Tread Aluminum Sheets for Sale - Low Price Aluminium Slab with Better Discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords