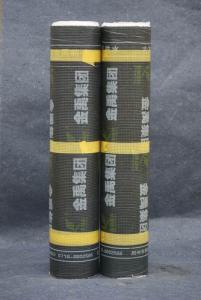

SBS modified bitumious waterproof material rolls

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Where to use:

Roofs or undergrounds

Pools, such as swimming pools, fire pools

Subways, tunnels, concrete road or bridge surfaces

Sewage plants, garbage burying projects

Penstocks

Advantages:

The combination of polyester fiber and SBS modified bitumen is showed good performance on waterproofness

It will be a high-strength membrane to resist water

Puncture-resisting, tear-resisting, corrosion-resisting, mould-resisting and weather-resisting

Good tensile strength and elongation

Strong adaptability for substrate shrinkage, deformation and cracks

Both high and low temperature resistance, especially in cold areas

Convenient to apply: use heat fusion method in all seasons

Packaging: SBS-PYPE material is packed in rolls with plastic bags.

Storage: SBS-PYPE material should be stored in well-ventilated shade place and protected from sun or rain. The temperature in stored places can not be higher than 50° C. It only can be put vertically in single-level. The normal shelf life is 1 year

- Q: How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane withstands freeze-thaw cycles by being designed with materials that can expand and contract without losing their integrity. These membranes are typically made of rubber or synthetic polymers that are flexible enough to accommodate the expansion and contraction caused by freezing and thawing temperatures. Additionally, they are formulated to resist water penetration even when subjected to these cyclical temperature changes, ensuring their effectiveness in preventing water damage.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. Some key requirements include ensuring a clean and dry surface, proper preparation of the substrate, correct application of the membrane according to manufacturer's instructions, and adequate curing time. Additionally, ensuring proper seam and joint treatments, as well as sufficient overlap and termination details, are essential for an effective waterproofing installation. It is crucial to follow the specific guidelines and recommendations provided by the manufacturer to ensure a successful and long-lasting waterproofing system.

- Q: Can a waterproofing membrane be installed underneath tile or other flooring materials?

- Yes, a waterproofing membrane can be installed underneath tile or other flooring materials to protect against moisture and water damage.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Yes, a waterproofing membrane can be used for temporary structures or tents. Waterproofing membranes are designed to provide a protective barrier against water, preventing it from penetrating the surface and causing damage. This makes them an ideal choice for temporary structures or tents, as they can effectively keep the interior dry during rain or other wet conditions. Additionally, waterproofing membranes are often lightweight and flexible, making them easy to install and remove, which is especially beneficial for temporary structures or tents that may need to be relocated or dismantled.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Yes, a waterproofing membrane can be used on metal block surfaces. Waterproofing membranes are versatile and can be applied to various surfaces, including metal blocks, to provide a protective barrier against water damage and leaks.

- Q: How does a waterproofing membrane ensure a watertight seal around penetrations?

- A waterproofing membrane ensures a watertight seal around penetrations by providing a protective barrier that prevents water from seeping through gaps or openings. It is designed to adhere tightly to the surface, creating a seamless and impermeable layer that seals off any potential entry points for water. This membrane acts as a shield, effectively preventing moisture from penetrating the structure and causing damage or leakage.

- Q: Can a waterproofing membrane be used for a retaining wall drainage?

- Yes, a waterproofing membrane can be used for retaining wall drainage. A waterproofing membrane is typically used to prevent water from penetrating through a structure, such as a basement or foundation. However, it can also be used in the construction of retaining walls to provide a barrier against water seepage. Retaining walls are designed to hold back soil and prevent erosion, but they can be susceptible to water damage if not properly constructed. Water seepage can cause pressure build-up behind the wall, leading to structural issues over time. By installing a waterproofing membrane on the backside of the retaining wall, it acts as a barrier to prevent water from infiltrating the soil and accumulating behind the wall. In addition to preventing water seepage, a waterproofing membrane can also aid in the drainage of water away from the retaining wall. By incorporating drainage systems, such as weep holes or French drains, in conjunction with the membrane, water can be directed away from the wall, reducing hydrostatic pressure and potential damage. It is important to note that while a waterproofing membrane can be used for retaining wall drainage, it is crucial to ensure proper installation and compatibility with the specific retaining wall system and conditions. Consulting with a professional engineer or contractor experienced in the construction of retaining walls is recommended to ensure the best approach for your specific project.

- Q: Is a waterproofing membrane compatible with different types of flooring materials?

- Yes, a waterproofing membrane is compatible with different types of flooring materials. A waterproofing membrane is designed to create a barrier between the subfloor and the flooring material, preventing moisture from seeping through and causing damage. This makes it suitable for use with various flooring types such as laminate, vinyl, tile, and even hardwood. The waterproofing membrane ensures that the flooring material remains protected from water damage, extending its lifespan and maintaining its appearance. However, it is important to note that different types of waterproofing membranes may have specific compatibility requirements, so it is recommended to consult the manufacturer's guidelines to ensure proper installation with the chosen flooring material.

- Q: What is the difference between PET waterproofing membrane and BAC waterproofing membrane? What is the commonality? Is BAC a PET?

- PET refers to polyethylene terephthalate, PET film using polyester composite film as the surface material, coated with rubber asphalt adhesive material, with cement mortar paste or self-adhesive. Can be constructed on the wet base surface, the grass-roots requirements are low, with high bond strength, bonding effect is good, not channeling water and so on.

- Q: Can a waterproofing membrane be used for a water tank sealant?

- Yes, a waterproofing membrane can be used as a water tank sealant. Waterproofing membranes are designed to create a barrier against water penetration, making them an effective choice for sealing water tanks and preventing leaks.

Send your message to us

SBS modified bitumious waterproof material rolls

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords