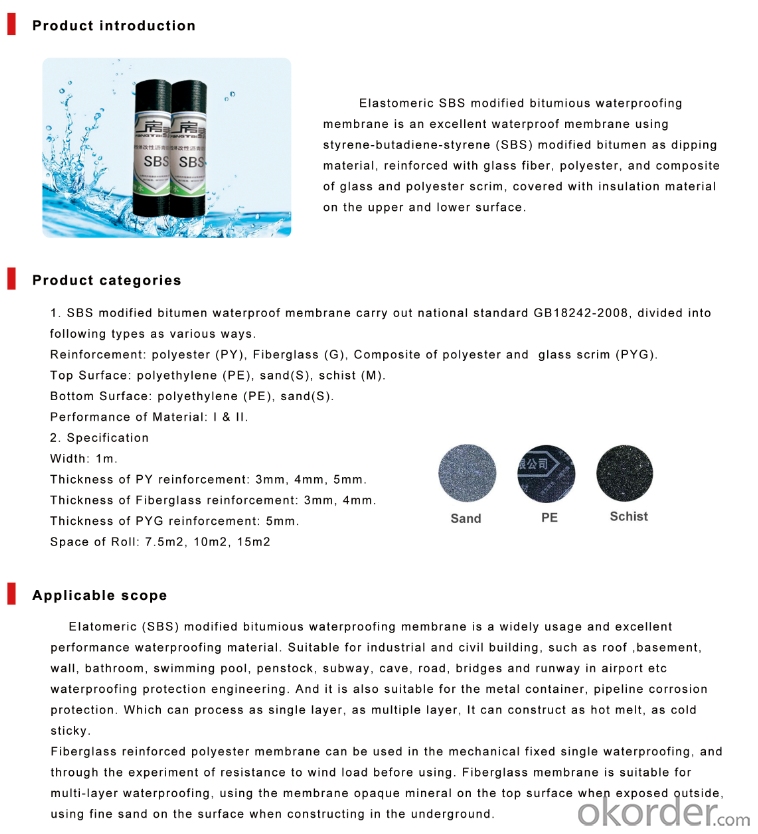

Elastomeric sbs Modified Bitumious waterproofing rolls for basement or roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Self-adhesive polymer modified bitumious waterproofing membrane using polymer modified bitumen adhesive material as main material(internal could have reinforcement),double or single coated with silicone oil isolating membrane or isolating paper as antiseize

II. Product Categories:

Reinforcement: no reinforcement (N) polyester (PY)

Top surface of N type: polyethylene (PE), polyester (PET), double sides adhesive without film (D).

Top surface of PY type: polyethylene (PE), sand(S), double sides adhesive without film (D).

Performance of Material: I & II. Thickness of 2.0mm of PY only have I type.

III. Product features:

The construction of the membrane is concise and environmental: without firing, remove the isolation can adhesive at the basic tightly, it's environmental and economic.

2. Good elongation and elasticity, so it could adapt to deformation and cracking of basic well.

3. The membranes adhesive performance with basic is excellent, can avoid running water.

4. The self-healing is strong. the adhesive layer can heal automatically to protect waterproof layer in the case of puncturing.

IV. Applicable scope:The waterproof membrane is suitable for industrial and civil roofing, basement, indoor, municipal engineering, reservoirs, swimming pool, subway, road and tunnel. It also used in wood and metal roofing especially suitable for oil depot, chemical factory, textile mill, granary etc.

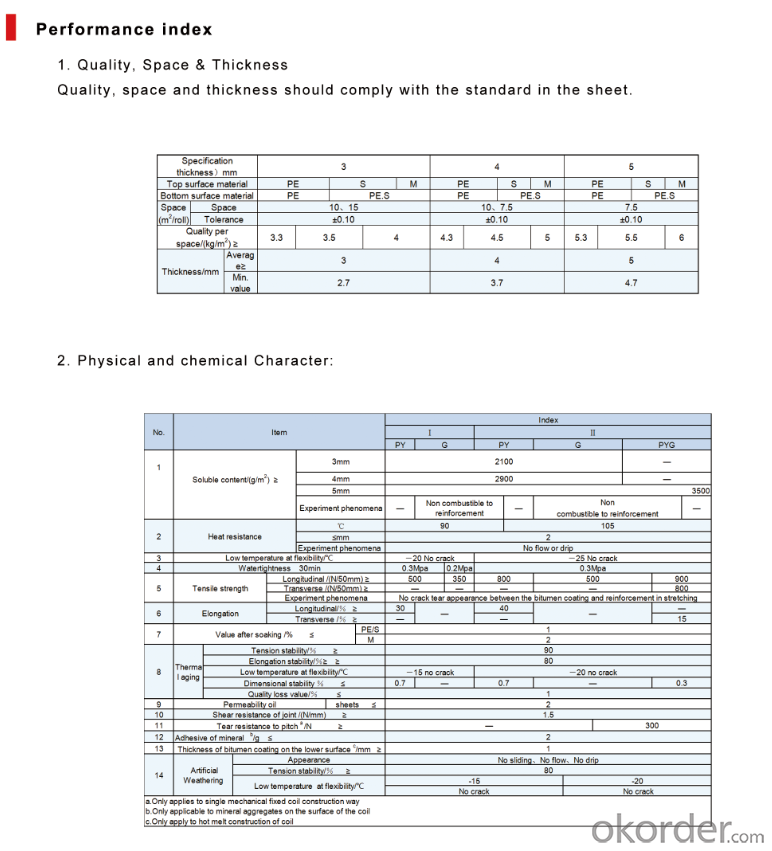

V. Performance index:

Physical and chemical Character of N type

No. | Item | Index | ||||||

PE | PET | D | ||||||

I | II | I | II | |||||

1 | Tensile strength | Tension(N/50mm) ≥ | 150 | 200 | 150 | 200 | -- | |

Longitudinal/% ≥ | 200 | 30 | -- | |||||

Bitumen elongation/% ≥ | 250 | 150 | 450 | |||||

Stretch phenomenon | Before membrane cracking no crack tear appearance between the bitumen coating and membrane in stretching | |||||||

2 | Tear resistance to pitch/N ≥ | 60 | 110 | 30 | 40 | -- | ||

3 | Heat resistance℃ | 70℃ sliding no more than 2mm | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | -20 | -30 | -20 | ||

No crack | ||||||||

5 | Watertightness | 0.2Mpa ,120Min | -- | |||||

6 | Peel strength N/mm ≥ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil | 2 | ||||||

9 | Holding power | 20 | ||||||

10 | Thermal aging | Tension stability/% ≥ | 80 | |||||

maximum tension elongation/% ≥ | 200 | 30 | 400 | |||||

Low temperature at flexibility/℃ | -18 | -28 | -18 | -28 | -18 | |||

No crack | ||||||||

Peel strength coil and aluminum plate N/mm ≥ | 1.5 | |||||||

11 | Heat stability | Appearance | No drum,fold,sliding,flow | |||||

Dimensional stability/%≤ | 2 | |||||||

Physical and chemical Character of PY type products

No. | Item | Index | ||||||

I | II | |||||||

1 | Soluble content/(g/㎡) | 2.0mm | 1300 | -- | ||||

3.0mm | 2100 | |||||||

4.0mm | 2900 | |||||||

2 | Tensile strength |

| 2.0mm | 350 | -- | |||

3.0mm | 450 | 600 | ||||||

4.0mm | 450 | 800 | ||||||

Maximun tension elongation/% ≥ | 30 | 40 | ||||||

3 | Heat resistance | 70℃ no sliding、no flow、no drip | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | |||||

No crack | ||||||||

5 | Watertightness 30min | 0.3MPa,120min | ||||||

6 | Peel strength/ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil/ amount of sheets ≤ | 2 | ||||||

9 | Holding power/min ≥ | 15 | ||||||

|

| maximum tension elongation/% | 30 | 40 | ||||

Low temperature at flexibility | -18 | -28 | ||||||

Peel strength Coil and aluminum plate/(N/mm)≥ | 1.5 | |||||||

Dimensional stability/% ≤ | 1.5 | 1.0 | ||||||

11 | Self-adhesive bitumen peel strength/(N/mm) ≥ | 1.5 | ||||||

Product Description

Construction Process

Test Machines

Certificates

Company Information

- Q: Can a waterproofing membrane be used in steam rooms?

- Yes, a waterproofing membrane can be used in steam rooms. Steam rooms generate high levels of moisture and heat, which can cause damage to the walls and floors. A waterproofing membrane creates a barrier that prevents moisture from seeping through and protects the underlying structure. It is essential to choose a membrane specifically designed for steam room application to ensure proper performance and durability.

- Q: Can a waterproofing membrane be used in earthquake-prone areas?

- Using a waterproofing membrane in areas prone to earthquakes is not only possible but highly advisable. This is because it serves as an effective shield against water infiltration, which can cause significant harm to buildings and structures during seismic events. The main purpose of waterproofing membranes is to create a barrier that prevents water from seeping in, thereby safeguarding the structural integrity of a building. Moreover, these membranes possess some degree of flexibility and elasticity, allowing them to absorb and distribute the forces exerted during an earthquake. This reduces the likelihood of cracks and leaks occurring. Nonetheless, it is crucial to ensure that the waterproofing membrane chosen is specifically designed and tested to meet the requirements of earthquake-prone areas. Factors such as the intensity and frequency of seismic activity in the region should be taken into account. Seeking advice from a structural engineer or waterproofing specialist is highly recommended to identify the most suitable waterproofing system for earthquake-prone areas.

- Q: How does a waterproofing membrane adhere to the substrate?

- A waterproofing membrane adheres to the substrate through the use of adhesive materials or mechanical bonding techniques. These can include the application of liquid adhesives, hot asphalt, or the use of mechanical fasteners such as screws or nails. The objective is to create a strong and secure bond between the membrane and the substrate, ensuring effective waterproofing and preventing water penetration.

- Q: Can a waterproofing membrane be used for underground fuel storage tanks?

- Underground fuel storage tanks can benefit from the application of a waterproofing membrane. This membrane serves as a barrier, preventing water and moisture from infiltrating the tank and causing corrosion or leaks. Given their underground positioning, these tanks are particularly susceptible to moisture infiltration. By utilizing a waterproofing membrane, the tank's integrity and lifespan are safeguarded through the provision of a sturdy and trustworthy waterproof seal. When selecting a waterproofing membrane for fuel storage purposes, it is vital to opt for one specifically formulated to endure the harsh conditions and chemicals associated with underground fuel storage.

- Q: Can a waterproofing membrane be used for below-grade parking structures?

- Yes, a waterproofing membrane can be used for below-grade parking structures. Waterproofing membranes are commonly used in construction to prevent the ingress of water and protect structures from water damage. In the case of below-grade parking structures, which are underground or partially underground, there is a higher risk of water infiltration due to the surrounding soil and groundwater. Waterproofing membranes are applied to the exterior surfaces of the structure, creating a barrier that prevents water from seeping through the walls and floors. These membranes are typically made of materials such as bitumen, rubberized asphalt, PVC, or polyurethane, which are highly resistant to water penetration. Additionally, some membranes may also have additional properties like crack-bridging capabilities or protection against chemicals or gases. It is important to consult with a qualified engineer or waterproofing specialist to determine the most suitable membrane for a specific below-grade parking structure, taking into consideration factors such as soil conditions, hydrostatic pressure, and local building codes.

- Q: Can a waterproofing membrane be used for balconies or decks?

- Yes, a waterproofing membrane can definitely be used for balconies or decks. Waterproofing membranes are specifically designed to protect surfaces from water damage, making them an ideal choice for outdoor spaces like balconies and decks that are constantly exposed to the elements. These membranes are typically made from durable materials such as rubber or polyvinyl chloride (PVC) and are applied directly to the surface of the balcony or deck. They create a barrier that prevents water from seeping into the underlying structure, which helps to extend the lifespan of the balcony or deck and prevent issues like rotting or mold growth. Additionally, waterproofing membranes can also provide added protection against UV rays, chemicals, and foot traffic, making them a reliable choice for enhancing the durability and longevity of balconies and decks.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Absolutely, government or municipal projects can most certainly utilize a waterproofing membrane. It is, in fact, a vital element frequently employed in the construction or refurbishment of diverse infrastructure projects like roads, bridges, tunnels, and buildings. The purpose of waterproofing membranes is to thwart water infiltration, which may inflict harm upon the structure and undermine its stability. By incorporating a waterproofing membrane, government and municipal projects can guarantee the endurance and robustness of their infrastructure, thereby diminishing the necessity for costly repairs or replacements in the future. Furthermore, these membranes also contribute to energy efficiency by preventing moisture intrusion, thereby reducing the potential for mold growth and enhancing insulation properties. All in all, it is highly recommended to integrate a waterproofing membrane in government or municipal projects to elevate the lifespan and functionality of the infrastructure.

- Q: Can a waterproofing membrane be used for a plaza deck?

- Yes, a waterproofing membrane can be used for a plaza deck. A plaza deck is a flat surface that is usually elevated and exposed to various weather conditions, such as rain, snow, and sunlight. Waterproofing membranes are designed to provide a barrier against water penetration and protect the underlying structure from moisture damage. They are commonly used in outdoor applications, including plaza decks, to prevent water infiltration into the building or structure below. By installing a waterproofing membrane on a plaza deck, it helps to ensure the longevity and durability of the deck, while also providing a safe and dry environment for pedestrians.

- Q: Can waterproofing membranes be used in basements?

- Basements can indeed benefit from the use of waterproofing membranes. These specialized membranes are designed specifically to act as a barrier against water penetration and are commonly employed in basements to effectively prevent moisture and water seepage. Typically composed of materials like rubber, bitumen, or polyethylene, these membranes are carefully applied to the walls and floors of the basement, creating an impermeable seal that keeps water out. By effectively stopping water from entering the basement, these membranes play a crucial role in safeguarding the foundation, walls, and interior spaces from the damaging effects of water, including mold and other moisture-related problems. Moreover, for comprehensive protection against water infiltration, waterproofing membranes can be utilized in conjunction with other waterproofing techniques like drainage systems and sump pumps.

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Gypsum block surfaces can benefit from the use of a waterproofing membrane. These surfaces are porous and can absorb moisture, making them naturally non-waterproof. By applying a waterproofing membrane, the infiltration of water, moisture damage, and mold growth on gypsum block surfaces can be prevented. The membrane acts as a barrier, repelling water and keeping it from penetrating the material. However, it is crucial to choose a suitable waterproofing membrane that is specifically designed for use on gypsum blocks and compatible with the particular type of gypsum block being treated. Moreover, to ensure the effectiveness and durability of the waterproofing membrane, proper surface preparation and application techniques must be followed.

Send your message to us

Elastomeric sbs Modified Bitumious waterproofing rolls for basement or roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords