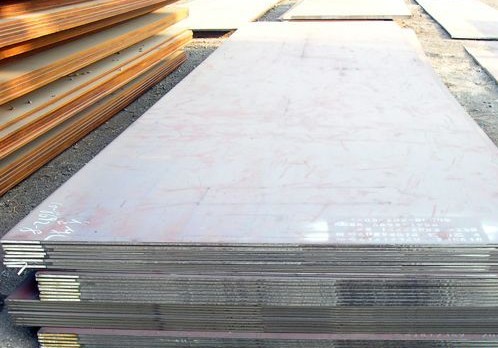

SA299B plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SA299A /SA299B vessel plate

SA299 is divided into two grade A, grade B.SA299A/SA299B is a kind of pressure vessel steel, common in the electric heater, nuclear power project with the container, which belongs to the thick steel plate. SA299A

main following pressure vessel steel plate: B61N-, P690QL1SA302GrC, SA203E/D, 13MnNiMoR, 13MnNiMo5-4,20MnMoR (20MnMo), SA299A/B, (DIWA353\BHW35), SA387MGr11, the corresponding domestic brands of 14Cr1MoR, 12Cr1MoV (R),

Chemical composition of SA299A: carbon (C) content of 0.28-0.30 manganese(Mn) plates less than 25mm melting analysis 0.90-1.40 product analysis of 0.84-1.52 plate is greater than 25mm melting analysis of 0.90-1.50, analysis of finished0.84-1.62 P max 0.035, Max 0.035 of sulfur, silicon smelting analysis of 0.15-0.40product analysis 0.13-0.45.

SA299A /SA299B vessel plate

SA299 is divided into two grade A, grade B.SA299A/SA299B is a kind of pressure vessel steel, common in the electric heater, nuclear power project with the container, which belongs to the thick steel plate. SA299A

main following pressure vessel steel plate: B61N-, P690QL1SA302GrC, SA203E/D, 13MnNiMoR, 13MnNiMo5-4,20MnMoR (20MnMo), SA299A/B, (DIWA353\BHW35), SA387MGr11, the corresponding domestic brands of 14Cr1MoR, 12Cr1MoV (R),

Chemical composition of SA299A: carbon (C) content of 0.28-0.30 manganese(Mn) plates less than 25mm melting analysis 0.90-1.40 product analysis of 0.84-1.52 plate is greater than 25mm melting analysis of 0.90-1.50, analysis of finished0.84-1.62 P max 0.035, Max 0.035 of sulfur, silicon smelting analysis of 0.15-0.40product analysis 0.13-0.45.

- Q: What are the different thickness tolerances for steel sheets?

- The thickness tolerances for steel sheets can vary depending on the specific grade and type of steel being used. However, common thickness tolerances for steel sheets typically range from +/- 0.001 inches to +/- 0.030 inches, with tighter tolerances typically being required for more precise applications.

- Q: What are the different types of surface treatments available for steel sheets?

- There are several different types of surface treatments available for steel sheets, each serving a specific purpose and offering unique benefits. 1. Hot-dip galvanizing: This is a widely used method where steel sheets are dipped in a bath of molten zinc, creating a protective coating that prevents corrosion. Hot-dip galvanizing provides excellent corrosion resistance and durability. 2. Electro-galvanizing: In this process, a layer of zinc is electrochemically deposited onto the steel sheets, creating a thin, uniform coating. Electro-galvanizing provides good corrosion protection and is often used for decorative purposes. 3. Powder coating: This surface treatment involves applying a dry powder onto the steel sheets and then curing it using heat. Powder coating provides a durable and attractive finish, offering protection against corrosion, UV rays, and chemicals. 4. Paint coating: Steel sheets can be coated with various types of paints, including epoxy, polyurethane, and polyester. Paint coatings provide aesthetic appeal and offer protection against corrosion and weathering. 5. Phosphating: This treatment involves applying a phosphate coating to the steel sheets, which enhances their corrosion resistance and improves paint adhesion. Phosphating is often used as a pre-treatment before painting or powder coating. 6. Chromate conversion coating: Also known as chromating or passivation, this treatment involves applying a thin layer of chromate onto the steel sheets. Chromate conversion coatings enhance corrosion resistance and improve paint adhesion. 7. Anodizing: Although primarily used for aluminum, anodizing can also be applied to steel sheets. This process involves creating an oxide layer on the surface of the steel, which enhances corrosion resistance and provides a decorative finish. 8. Pickling: This treatment involves immersing the steel sheets in an acidic solution to remove scale, rust, and other impurities. Pickling leaves the steel sheets with a clean, smooth surface, ready for subsequent treatments or processes. Overall, the choice of surface treatment for steel sheets depends on the intended application, desired appearance, and level of corrosion resistance required.

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- Plain carbon steel sheet and stainless steel sheet are both types of steel sheets, but they have several distinct differences. The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made up of iron and carbon, with small amounts of other elements such as manganese and silicon. It is known for its strength and durability, making it suitable for a wide range of applications. However, plain carbon steel is prone to rust and corrosion when exposed to moisture or certain chemicals. On the other hand, stainless steel sheet is made up of iron, carbon, and a minimum of 10.5% chromium. This addition of chromium forms a protective layer on the surface of the steel, known as a passive film, which prevents corrosion and rusting. Stainless steel is highly resistant to stains, heat, and corrosion, making it ideal for applications where hygiene and durability are crucial, such as in the food and medical industries. Another significant difference between the two types of steel sheets is their appearance. Plain carbon steel sheet has a dull grey finish, while stainless steel sheet has a shiny, reflective surface. This aesthetic difference is often a consideration in industries where the visual appeal of the material is important, such as architectural or interior design applications. Furthermore, stainless steel sheet has a higher price point compared to plain carbon steel sheet. This is due to the additional alloying elements, such as chromium and nickel, which are added to enhance its corrosion resistance and other properties. The higher cost of stainless steel is often justified by its superior performance and longevity in corrosive environments. In summary, the key differences between plain carbon steel sheet and stainless steel sheet are their composition, properties, appearance, and price. Plain carbon steel is strong but prone to rust, while stainless steel is corrosion-resistant and has a shiny finish. The choice between the two depends on the specific requirements of the application, including the need for corrosion resistance, aesthetics, and budget.

- Q: How do steel sheets perform in corrosive environments?

- Steel sheets perform well in corrosive environments due to their inherent resistance to corrosion. The presence of elements like chromium, nickel, and molybdenum in steel alloys forms a protective oxide layer that prevents direct contact between the steel and corrosive agents. This helps in preventing rust, degradation, and ensures the longevity of steel sheets even in harsh conditions.

- Q: Are the steel sheets resistant to bending or warping?

- Yes, steel sheets are highly resistant to bending or warping due to their inherent strength and rigidity.

- Q: What is the thermal conductivity of steel sheets?

- The thermal conductivity of steel sheets typically ranges between 50 and 60 Watts per meter-Kelvin (W/mK).

- Q: What is the difference between color steel plate and hot galvanized sheet?

- Color steel plate is divided into two kinds, one is hot galvanized after spraying color, not a hot galvanized plate directly after spraying, hot galvanized and color steel plate is a kind of anti-corrosion measures, galvanizing after spraying outdoor powder, not only has good antiseptic effect, and the color is beautiful, just hot galvanized plate no antiseptic, decorative effect

- Q: What are the different types of surface finishes available for steel sheets?

- Some different types of surface finishes available for steel sheets include hot rolled, cold rolled, galvanized, and coated finishes.

- Q: What are the different edge finishes available for steel sheets?

- Some of the different edge finishes available for steel sheets include mill edge, sheared edge, slit edge, deburred edge, and rounded edge.

- Q: Can steel sheets be used for decorative wall panels?

- Yes, steel sheets can be used for decorative wall panels. They can provide a modern and industrial aesthetic to a space and offer durability and versatility in design options.

Send your message to us

SA299B plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords