S690QL1 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

S690QL1 steel high strength steel S690QL1

S590Q, S690Q, S690QL, S690QL1, WQ690D, Q550D, WQ590D, WH70Q,WDB620E, WH785E

The content of elements - [maximum early

A maximum of 0.50 Mo Cu, a maximum of 0.70, maximum 0.06 Nb, 2 Ti Ni maximum,a maximum of 0.05, maximum 0.12 V, 0.15 Zr maximum

Executive standard: EN10025-6, I like GB/T16270-2009

S690Q used in the manufacture of low temperature resistance, high strength of thekey parts, construction machinery, mining machinery structure, is of high strengthstructural steel plate.

S690Q: the yield strength of sigma 0.2 > 690- > 650 MPa, S690Q: the ultimate tensile strength of B 770-940MPa, S690Q: extension rate greater than 14 Delta 5%, S690Q:-20 C V impact work vertical is greater than or equal to 30J. I like

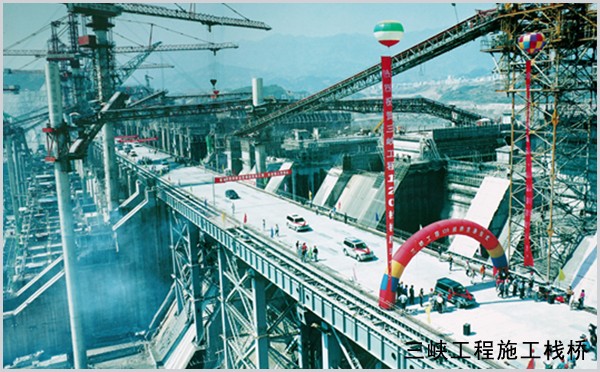

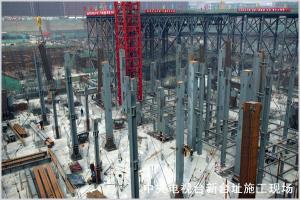

S690Q high strength steel plate, quenching and tempering heat treatment method,main use: manufacturing of all kinds of mechanical engineering, such as various types of mines and construction projects for the drilling rig, excavator, electric wheel dump truck, mine car, excavators, loaders, bulldozers, cranes, various typesof hydraulic support in coal mine mechanical equipment and abrasion proof structure; widely used in petrochemical industry, power plants and other industries,for the production of separator, nuclear reactor pressure shell, liquefied petroleum gas cylinders, hydropower station high pressure water pipe, water turbine voluteequipment and components

Plate for bridge: Q235qC Q345qC Q370qC Q420qC14MnNbq

Construction plate: Q235GJC Q345GJC Q390GJC Q420GJC Q460GJC

Shipbuilding: A B D E AH32/36 DH32/36 EH32/36 2hgr50 AH40 DH40 EH40

Grinding plate: S48-50 P20 718 WSM30A P80A 6388: X50 X56 X60 X65 pipeline steel X70

Wear resistant steel plate: NM360 NM400

High strength steel WH70Q WQ590DQ550D

- Q: What material can be used for A36 steel plate?

- The A36 plate is used instead of the standard Q345 American Standard.

- Q: What are the common lengths of steel sheets?

- The common lengths of steel sheets vary depending on the specific industry and application, but they typically range from 6 to 12 feet.

- Q: How do steel sheets perform in marine environments?

- Steel sheets perform well in marine environments due to their high strength and corrosion resistance. The steel's protective oxide layer helps prevent rusting and deterioration caused by saltwater exposure. Additionally, steel sheets can withstand the harsh conditions of marine environments, including waves, moisture, and extreme temperatures, making them a reliable choice for various marine applications such as shipbuilding and offshore structures.

- Q: How are steel sheets manufactured?

- Steel sheets are manufactured through a process called hot rolling, where molten steel is passed through a series of rollers to reduce its thickness and shape it into a flat sheet. This process involves heating the steel to high temperatures, then rapidly cooling it to increase its strength and durability.

- Q: How can steel sheets be protected from corrosion?

- Steel sheets can be protected from corrosion through various methods such as applying protective coatings like paint or galvanization, implementing cathodic protection techniques, using corrosion inhibitors, or ensuring proper maintenance and regular inspection to identify and address any potential corrosion issues promptly.

- Q: Are the steel sheets perforated or solid?

- Perforation has been applied to the steel sheets.

- Q: Can steel sheets be used in earthquake-resistant construction?

- Yes, steel sheets can be used in earthquake-resistant construction. Steel has excellent strength and ductility properties that allow it to withstand the forces generated during an earthquake. Additionally, steel sheets can be easily fabricated, assembled, and incorporated into various structural systems, making them a popular choice for earthquake-resistant construction.

- Q: What is reinforced steel plate?

- Generally speaking, steel plates are just spoken words, no specific brand or brand nameStrengthening steel plate refers to the stress intensity of steel plate, such as low alloy high strength plate, high quality carbon structural steel and high quality carbon spring steel, etc.

- Q: Can steel sheets be used for shipbuilding?

- Yes, steel sheets can be used for shipbuilding. Steel is a popular material choice for shipbuilding due to its strength, durability, and ability to withstand harsh marine environments. Steel sheets are commonly used to construct the hull, decks, and various structural components of ships.

- Q: What is the average cost of stainless steel sheets?

- The average cost of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the thickness of the sheets, the size of the sheets, and the supplier. On average, stainless steel sheets can range in price from $30 to $300 per sheet. Lower-grade stainless steel sheets tend to be more affordable, while higher-grade ones can be more expensive. Additionally, thicker sheets are generally more costly than thinner ones due to the increased amount of material used. It is important to consider these factors and shop around to find the best price and quality that suits your specific needs.

Send your message to us

S690QL1 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords